Single Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Single Component Polyurethane Waterproof Coating Introduction

Single component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof film after

coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

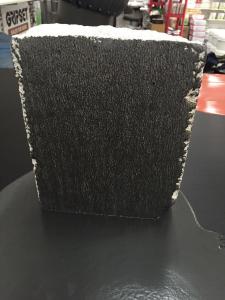

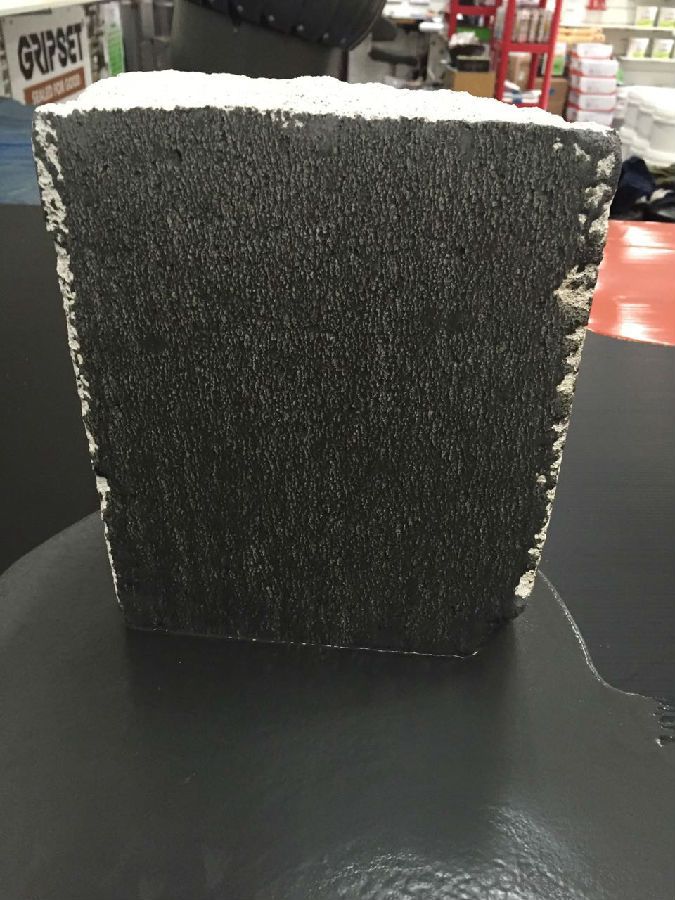

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Slope roof drains do not need to be waterproof

- When installing a waterproof board, when the width of a waterproof board is not enough, to be placed side by side, it should be noted that the gap between the board and the plate will provide potential space for root growth.

- Q: A complete set of basement waterproof construction program

- Second, the basement of the external walls of water leakage construction preparation 2.1 Technical preparation 2.1.1 Selection of construction methods Waterproof engineering is related to the use of the project an important indicator, it is the construction process of a key project, difficult engineering. The choice of construction methods and programs has a direct impact on the quality of construction. The underground wall of the project SBS waterproofing membrane with hot melt method full construction. 2.1.2 before the start of the project, the first organization of engineering and technical personnel to enter the construction site, to understand the situation, to further understand the characteristics of the project to solve the contradiction between the construction technology and the implementation process. 2.1.3 technology before the end of the construction of waterproofing works by the professional foreman in accordance with the construction drawings and the existing national norms require the actual situation of the project to the construction team in writing to the end. The contents include construction site, construction sequence, construction technology, construction level, node fortification method, enhancement site and practice, project quality standard, guarantee the quality of technical measures. And after the field technical person in charge of the strict implementation of the audit.

- Q: How to do waterproof bathroom, construction process is what

- First, the bathroom waterproof method: 1, brush the first time waterproof coating. Before the construction to ensure that the ground dry, waterproof coating to be painted, no omission, and the combination of solid grass, no cracks, no bubbles, no shedding phenomenon. Brushing the same height, the thickness of the product requirements to meet the requirements.

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: How does the finished ventilator manufacturer waterproof?

- Rooftop natural ventilator waterproofing measures are mainly two kinds, one is the traditional silicone, adhesive tape waterproof, the other is the structure of water, the national standard Atlas 11CJ33 "ventilation and light skylight" recommended the use of structural waterproof technology.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- Plastic runway construction should pay attention to: 1, before the construction, must be on the asphalt concrete foundation for quality acceptance, acceptance criteria according to design standards and technical specifications, the plastic runway in the corresponding drainage facilities, can be used around the clock. The ambient temperature should be controlled at 5 ℃ ~ 38 ℃, to avoid below 5 ℃, 38 ℃ above the ambient temperature operation, the relative humidity control below 70%, the foundation requires a clean, according to the temperature and relative humidity to adjust the amount of catalyst The curing speed control appropriate. Color paste and prepolymer storage, the lid to be tightened, before use to detect moisture, qualified after use, the water in the foundation should also be controlled to avoid the bubble after the glue. Plastic pavement materials must be carefully checked when the quality inspection certificate and validity period.

- Q: Villa roof leakage what general reasons, what materials to remedy

- Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- First, rigid (concrete) waterproof roofing SBS membrane should not be painted before the coating of any waterproof coating, otherwise it will damage the bonding strength of the coil and the grassroots.

Send your message to us

Single Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords