Single component Polyurethane waterproofing coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

01 Product introduction Product Introduction

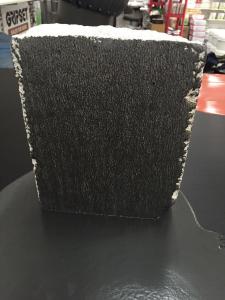

Single-component polyurethane waterproof coating, the main components of isocyanate, polyether polyol, and a variety of functional additives prepared by the reactive elastomer waterproof coating. Its waterproof film forming mechanism is to cure cross-linking with water vapor in the air after contact, forming a three-dimensional network structure, forming a layer of flexible and strong overall waterproof film on the surface of the substrate, so as to achieve a better waterproof effect.

02 Product characteristics

1. High construction efficiency, convenient and fast: single component, ready to use;

2. Good mechanical properties: reactive waterproof material has large tensile strength, high elongation, strong adaptability to base cracking and expansion;

3. Low temperature flexibility is very good :-35℃ bending without cracks, ordinary waterproof materials can not do, suitable for low temperature waterproof projects;

4. Strong bond with the base: no need to brush the base treatment agent, the bond strength can reach 1.0MPa;

5. Excellent water resistance: wet curing reactive polyurethane coating, the coating is dense, no pinholes, no bubbles, water permeability coefficient is small, can be waterproof and can be used as a gas insulation layer;

6. Green environmental protection: the use of low volatile solvent, non-dangerous goods. Does not contain benzene, toluene, xylene and other harmful solvents.

03 Applicable scope

1. Basements and roofs of industrial and civil buildings, large venues;

2. Subways, tunnels, Bridges;

3. Kitchen bath room, swimming pool, water channel;

4. Parts with complex shapes that are not easy to coil construction, such as vertical and horizontal parts of pipelines.

04 Packaging and storage andtransportation

1. Pay attention to safety during storage and transportation, avoid sun and rain, prevent extrusion collision, stay away from fire source and heat source, pay attention to ventilation and drying.

2. Storage temperature should be 5-40℃.

3. Under normal storage and transportation conditions, the storage period is 6 months.

【 Product Specification 】20Kg/ barrel

- Q: How to do waterproof bathroom, construction process is what

- First, the bathroom waterproof method: 1, brush the first time waterproof coating. Before the construction to ensure that the ground dry, waterproof coating to be painted, no omission, and the combination of solid grass, no cracks, no bubbles, no shedding phenomenon. Brushing the same height, the thickness of the product requirements to meet the requirements.

- Q: Eastern rainbow waterproof how to do

- Do not know where you use, waterproof as if a lot of materials. I know there are coiled, painted.

- Q: What is PE waterproof cloth and PVC tarpaulin

- The characteristics and performance index of waterproof cloth products 1. Tensile strength index: warp strength ≥ 2100N / 5CM, zonal strength ≥ 1600N / 5CM; 2. No leakage of water, water pressure ≥ 2000MM water column; 3. Low temperature, cold temperature -20 ℃; 4 Can be mildew, mildew experiment for the first level. Product Usage 1. Can be used car, train, ship cargo tarpaulin; 2. It can be used for the open storage of the harbor airport at the station terminal harbor; 3. Can be set up temporary granary and a variety of crops covered with open-air; 4. Can be used for construction site power construction site and other sites to build temporary shed, temporary warehouse materials; 5. Can be processed camping with tents and various machinery and equipment outside the jacket.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Between the glass and the wall is generally waterproof with waterproof glue, the specific steps are as follows: First, clean the surface Remove the surface of the joints of water, grease, dust and other pollutants, with a clean cloth to clean all the residue, so that the surface clean and dry. (If it is waterproof glue, the surface should be flat and clean, plastic gap to slightly curved as well.)

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: Js waterproof coating without powder can brushing

- 5. Coating maintenance: JS cement-based waterproof emulsion coating construction after 24 hours after the end with a damp cloth to cover the coating or spray water to maintain the coating, usually 2-3 days; air humidity, poor ventilation of the local dry The time period may be longer, and vice versa; 6. Check the construction of JS waterproof coating (closed water test): bathroom, pool and other parts in the JS cement-based waterproof emulsion waterproof layer after dry (at least 24 hours in summer, at least 48 hours in winter) stored water for 48 hours to see the water Construction is not qualified. Light wall must do the water test. JS waterproof coating See the amount of: under normal circumstances, the amount of about 0.6-1kg / ㎡, the actual amount from the use, the use of parts, rough surface roughness, environmental factors such as the decision.

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Construction of roof waterproofing membrane First, the process (hot melt construction) Clean up the grass-roots → brushing the primary treatment agent → paving the film additional layer → paving the film → hot melt sealing side → water test → protective layer

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 4: coating waterproof layer coating evenly, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm not exposed at the end.

Send your message to us

Single component Polyurethane waterproofing coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches