Non-Woven Fabric Breathable Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non-Woven Fabric Breathable Waterproofing Membrane

Introduction:

Breathable Membrane is a water resistant membrane but with high vapor permeability, use as diffusion open roofing felts under pitched roof tile or vapor permeable barrier house wraps on timber frame walls.

Breather membrane functions as a weather-resistant barrier, preventing rain from getting into the roof or wall assembly while allowing water vapor to pass to the exterior.

Breather membrane may also serve as an air barrier if it is sealed carefully at seams.

Breathable Membrane have good "water resistance", good "water vapor permeability", and good "air barrier properties". Weather Proof House Wrap.

Specification:

Surface mass density | 80 g/m² | ||

Roll size | 1.5m*50m or customized | ||

Vapor permeability | ≥2250 g/m²/24h | ||

Sd value | 0.02 m (-0.005/+0.015) | ||

Water tightness | class W1 | ||

Tensile strength MD/CD | 105/70N/50 mm (+/-20%) | ||

Tearing strength MD/CD | 50/60 N (+/-20%) | ||

Resistance to UV rays | 3 months | ||

Reaction to fire | Class F | ||

Loading quantity | 20’GP | 40’GP | 40’HC |

By bulk (1.5*50) | 1140rolls | 2450rolls | 2700rolls |

With pallets (1.5*50m) | 900rolls | 1954rolls | 2122rolls |

Jumbo rolls (1.5*3500m) | 14rolls | 30rolls | |

Advantages:

1)Excellent performance at water resistance

2)Particular function of water vapor permeability

3)Good performance at UV resistant for 3 months

4)They are much lighter than bitumen felts, suitable for construction in different condition

5)They have excellent tensile and tearing strength

6)100% recyclable

7)Simple installation in new building, re-roofing and refurbishment situations

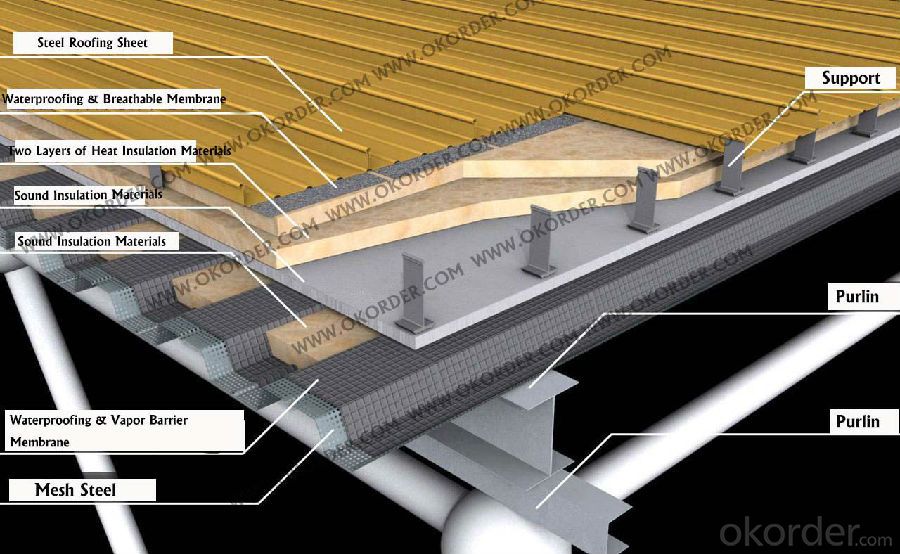

Typical Installation:

Typical Application:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: How to do waterproof bathroom, construction process is what

- First, the bathroom waterproof method: 1, brush the first time waterproof coating. Before the construction to ensure that the ground dry, waterproof coating to be painted, no omission, and the combination of solid grass, no cracks, no bubbles, no shedding phenomenon. Brushing the same height, the thickness of the product requirements to meet the requirements.

- Q: What is the car waterproof sticker material?

- C. metal technology and other: metal technology refers to the aluminum plate and other metal plate through the machine to suppress the concavity and convex surface, and then made of metal paint color, and finally after grinding, drawing and other production of the car stickers (car standard); Area can not be too large, can only be used for a small range of iconic car stickers.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- As the SBS coil finished with pure asphalt is not the same, the coil includes a variety of surface material weight. The following is the different types and different thickness of the SBS coil unit area weight, due to the need to lap and pave the reinforcement layer, calculate the load in the following unit area weight, the general multiplied by 1.2 coefficient.

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Third, security measures 1, firmly establish the "safety first, prevention first" safety production policy. Before the operation, the site management personnel must be to the operation team to carry out security technology to the end, and actively carry out pre-class security activities, security personnel check, supervise. 2, the roof around the poles outside the scaffolding (protective railings), roof construction is strictly prohibited removal. 3, roof construction, debris and other materials is strictly prohibited from the roof directly down throwing. 4, storage of coils and adhesives warehouse or site to prohibit the fireworks, for the use of fire, there must be fire prevention measures, and should set a certain number of fire extinguishers and sand bags. 5, oil drums should be flat, not two carrying, in the transport process, pay attention to balance, the spirit to focus, to prevent accidental fall caused harm. 6, transported to the roof of the material, should be scattered on average, with the use of transport, not concentrated stacking. 7, the use of torch, you should clear the surrounding flammable items, must be away from the base of oil, is strictly prohibited in the brush base oil area using the torch. Torch petrol should not be over full, cheer should not be too much, in the fire site must be equipped with fire equipment.

- Q: FRP finished brush on what can be waterproof do not fade

- With glass fiber reinforced plastic + color paste even after the use of. Can be waterproof.

- Q: What are the key points and contents of the quality control of waterproof material?

- 2, ordinary two-component polyurethane: A material is similar to the appearance of edible oil translucent yellowish curing agent from polyether and isocyanic acid by polycondensation of polyurethane prepolymer (about 20,000 yuan / t), B material For the plasticizer, coagulant, fillers and other components of the black liquid (about 3900 yuan / t), after mixing the polyurethane coating is also black. But also because of A, B material of the huge spread so often the following two kinds of fraud: ① with a very cheap black oil (priced at only about 1,200 yuan / t), diluted with xylene after thin coating twice. Cold oil is not easy to dry after the coating, after each coating must be drying a few days, in the winter with roasted, and then do not sprinkle dry powder cement, so a long time paint are dry. ② is often used to expand the proportion of A, B components such as 1: 4-6 (usually 1: 2), but also in the polyurethane mixing process by adding cement powder as a filler, if the stirring is not added xylene diluted Agents and other methods of fraud.

- Q: Villa roof leakage what general reasons, what materials to remedy

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. First look at the roof there is no crack, the original waterproof layer is not aging, the roof of the original waterproof membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking, and roof On the gutter there is no clogging.

- Q: How can the toilet waterproof works fail?

- After the failure of the bathroom waterproofing project to solve the specific needs of the specific analysis of targeted treatment. ??????? Bathroom waterproof is the problem more decoration works. The main reasons are: 1, construction (local, details, etc.); 2, waterproof material problems; 3, the structure (such as uneven settlement, cracking, etc.); 4, to save a little waterproof waterproof measures. ???????? After the three must be redo waterproof, the first type of reasons can be used to the appropriate remedial measures, pay the table "bathroom waterproof failure part of the phenomenon and the remedy list." ??????? Please responsible professionals in the field to carefully check the judge to find specific reasons for dealing with the need to destroy the red or must be destroyed, do not affect others after causing greater losses. The following are the same as the "

- Q: Waterproof material water leakage construction should pay attention to what

- 3, do the closed water test After the waterproof construction is completed, the water storage test. Will be blocked all the toilet outlet, the door at a pound of about 200mm high barrier, and then poured in the bathroom about 20mm ~ 30mm deep water, and 24 hours after the inspection of the walls and the ground around the leakage phenomenon , Waterproof test is to ensure the quality of the bathroom waterproofing the key, we must do. Such as after 24 hours without leakage as qualified. If you find a leak, you should immediately stop the water storage test, re-waterproof layer to improve the treatment, after passing the water test.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar is good, easy to mix, is conducive to the improvement of masonry and work efficiency; cement sand waterproof, suitable for wall paste wall, wall light

Send your message to us

Non-Woven Fabric Breathable Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches