One Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material, suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof film after coating. It is a new type of environmental friendly waterproof material without solvent.

Application:

Building roof

Concrete

Wall

Water Tank Structure

Floor(kitchen floor, bathroom floor ect)

Underground Tunnel

Sewerage Structure

Movement Joint

Wet Area, Pipes, Sewer & etc.

Advantages:

Water based and solvent based

Solid content above 80%

Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

Good splicing performance

Operate conveniently, low viscosity

Can splicing with concrete and many kinds board stuff

Will not change color after used

Apply for Roof,Swimming Pool,Tank and more

Specifications:

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

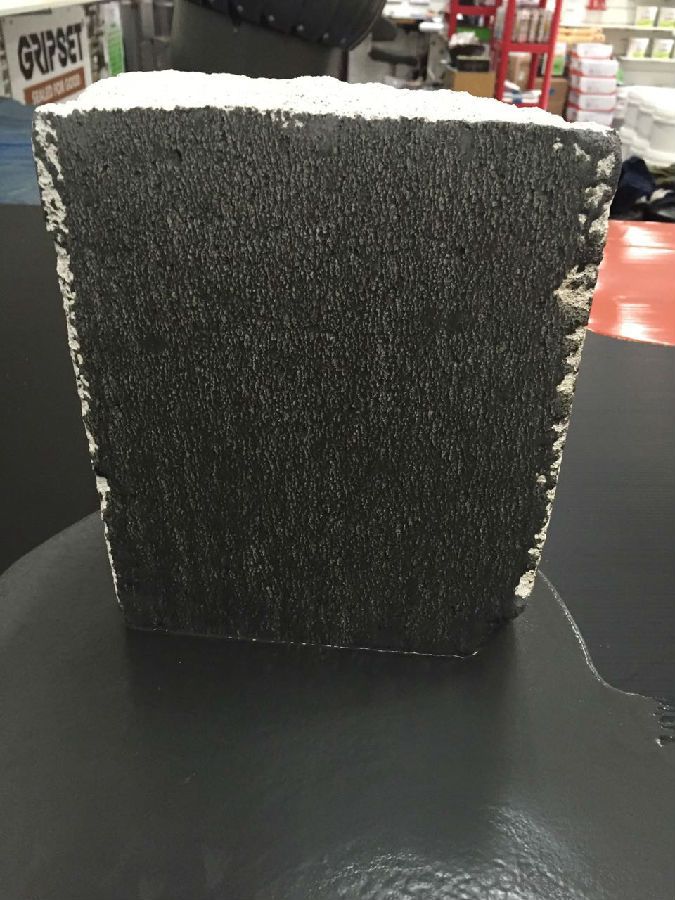

Images:

FAQ:

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed.

With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the

world. Warmly welcome your samples requirement or trail order.

- Q: Bathroom first leveling or do waterproof, what is the difference

- 7. The threshold stone is only decorated, do not mistakenly believe that can hold water. In short, each process have to carefully do not leave a hidden trouble to ensure worry. But the reality of the structure, materials, workers, mutual protection and many other unsatisfactory, so that waterproof is a common problem, perhaps set (overall) bathroom by the factory as a whole production test, on-site assembly will solve this common problem.

- Q: A complete set of basement waterproof construction program

- 2.2 site preparation 2.2.1 external wall of the pull bolts should be cut off in advance, wooden blocks removed after the use of cement mortar smooth. 2.2.2 grass-roots should be clean, concrete joints processing flat, made at the corner of the yin and yang ...

- Q: What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Finished products to buy relatively easy to do some of the cabinet to do more solid material more assured because the plate is also a long-term environmental protection or woodworking directly do better feel that the company can quote their own under the woodworker comparison

- Q: How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet is a relatively stable part of the home improvement structure, it is recommended to do waterproof mortar waterproofing agent on it, mortar waterproofing agent not only with the base surface bonding firm, and puncture resistance, high strength, waterproof life and construction Material with the life, the construction of relatively waterproof coating is also relatively simple.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: I would like to ask how to do in the warm water above,

- 1, I think the flexible mortar, waterproof paint better, because these materials in the construction process, not to warm the temperature caused too much impact, if the shop waterproofing membrane is too heavy, may affect the warm heat. 2, generally in the floor before the warmth, first do a waterproof, paved to warm to do once.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 3: waterproof gypsum board ????Waterproof gypsum board is in the gypsum core by adding a certain amount of waterproof plastic made of products, so waterproof gypsum board has a certain waterproof function, while gypsum board paper is also a waterproof measures, is a more widely used materials. Waterproof gypsum board with the effect of thermal insulation, but also has the advantages of fire, noise, but also an easy decoration materials. There is also a feature of the characteristics of environmental protection, due to the use of natural gypsum as a raw material, in the home environmental protection is guaranteed.

- Q: How does the waterproofing membrane work?

- 3, the ignition: first open the liquefied gas cylinder switch, and then hand gun slowly open the gun switch, to be heard when the gas hissing sound, ignite the flame, and then adjust the switch, the flame was blue. Ignite people should stand behind the nozzle side, so as not to be burned by fire;

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar is good, easy to mix, is conducive to the improvement of masonry and work efficiency; cement sand waterproof, suitable for wall paste wall, wall light

Send your message to us

One Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords