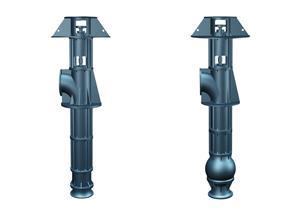

Vertical Booster Pump For Domestic Home Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Centrifugal Water Pump for Agriculture Application

1.Structure of Centrifugal Water Pump Description

Centrifugal Water Pump is used for transporting pure water or liquids with physical and chemical properties similar to pure water, and the maximum of the medium temperature is 80°C.(type ISR pump reaches 120°C).

Widely applied towater supply industry, urban water supply and drainage, metallurgy, power stations, textile, chemical industry, printing and dyeing, ceramics, rubber, heating, waste heat utilization, air conditioning, agricultural irrigation and etc.

2.Main Features of the Centrifugal Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3. Centrifugal Water Pump images

4. Centrifugal Water Pump Specification

Item | Diesel Water Pump |

Diesel Pump | Agricultural Irrigation Desel Water Pump |

Model | IS |

Material | Cast iron |

Mode | Horizontal |

Color | Blue and adjustable |

Theory | Centrifugal Pump |

Structure | Single-stage Pump |

Usage | water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Transporting pure water or liquids |

Outlet Diameter | 32-250mm |

Capacity | 6.3-400m3/h |

Head | 5-125m |

Rotation Speed | 1450-2900r/min |

Power | 0.55-110kW |

Warrenty | 1 Year |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: What is a water pump coupling device?

- The water pump coupling device comprises a coupler, a coupling flange, a guide rod and an upper fixing plate, wherein the contact surface of the coupling base and the coupling slide plate is provided with an annular groove, and a soft sealing gasket is tightly fixed on the groove. By adopting the structure, the coupling contact surface of the coupling slide plate and the coupling base is sealed firmly by an annular sealing groove

- Q: What is the pump lift voltage? And how to suppress the pumping voltage rise?

- The reverse voltage and torque electric torque instead, and the motor has strong braking torque, forcing the rotor quickly stopped, but usually AC-DC-AC converter is the main power AC/DC rectifier circuit is irreversible, and therefore can not return to the power grid, resulting in the main circuit of the capacitor voltage increases two that is called the pump voltage.

- Q: Why can the centrifugal pump hold down the pressure?

- The centrifugal pump can hold pressure because of the suction pipe in the pump at the entrance of a non-return valve (valve).

- Q: I live on the 8 floor. Often there is no water. Life is very inconvenient. What kind of pump do I have to install? What should I pay attention to when I buy it? What's the pump for that brand? Should it be installed in that position?

- (8) check the suitability of the foundation and whether the size of the foundation corresponds to the size of the pump.(9) find the position of positive pump and motor, pump set and anchor bolt and the inlet and outlet flanges, to ensure that the flange torque of the pump conforms to the standard. Check the inlet and outlet piping before alignment. Make sure the weight of the inlet and outlet pipe does not exert force or torque on the pump. When looking for, should also pay attention to eliminate the pump rotor movement, so as to avoid the end gap error. If checked after the pump is working, it should be carried out under cold condition. It is important to draw attention to the fact that the pump set of the complete set of factory is only rough looking (checked with a ruler) when it is shipped. It may cause displacement when it is transported.

- Q: Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- 3. efficiencyVolume efficiency, for hydraulic pumps, is the ratio of actual flow to theoretical flow. A hydraulic motor is the ratio of its theoretical flow to its actual flow.Mechanical efficiency, for hydraulic pumps, refers to the ratio of theoretical torque to actual input torque. The actual output torque of the hydraulic motor is theoretical torque to overcome the torque after friction, so the mechanical efficiency is the ratio of the actual output torque to the theoretical torque.

- Q: What is the function of the heating pump system for the water pump design?

- Will cause some of the internal friction gap disappeared, the coupling center damage. In this case, starting the pump inevitably results in vibration, friction, etc.

- Q: How can I buy a pump?

- 3 、 mechanical requirements of high reliability, low noise, vibration.4, the correct calculation of pump procurement costs, the pump manufacturer to inspect, requiring good quality equipment, good after-sales service, spare parts can be timely supply.The micro pump and the motive of the mechanical energy or other external energy transmitted to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids.The technical parameters of pump performance include flow, suction, lift, shaft power, water power, efficiency and so on.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- Regeneration of the filter medium is required to regain the filtration capacity of the medium. The regeneration process is mainly accomplished by the backwashing pump (the backwash pump is not a special pump, referring to the pump for the completion of the process). The working principle is through the cleaning liquid from the downstream of the filter into the backwash pump (alkali, acid and water), reverse flushing filter medium, cleaning liquid discharged from the upstream, this process can be attached to the dielectric surface and internal impurities washed away.

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Submersible pump is best in the water, if dry pumping will cause burns.

- Q: Why adjust the centrifugal pump outlet valve can adjust the flow? What are the advantages and disadvantages of this method? Is there any other way to regulate the flow of the pump?

- This method can be used to regulate flow. The advantage is that it is simple and easy to use and the disadvantage is that the throttle consumes energy

Send your message to us

Vertical Booster Pump For Domestic Home Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords