Non-negative Pressure Building Water Supply Pump in Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non-negative Pressure Building Water Supply Pump in Building

1.Structure of Non-negative Pressure Building Water Supply Pump in Building Description

High Pressure Booster Pumps is a high efficient water facility has characters of easy installation,saving space, water pool is not required.The pump energy efficient, using I mm converter speed control valve control over a large number of energy saving, the elimination of the high level of secondary pollution of water tanks,water tank eliminates the need to wash the cost and trouble,Water Pump achieve soft-start, start on the grid to reduce the impact of pumps to extend life.

2.Main Features of the Non-negative Pressure Building Water Supply Pump in Building

Water Supply: Urban water supply, boiler or condensate system, water filtering and distribution, water to water district, in charge of pressurized, high-rise building pressurization.

Industrial boosting: process water system, cleaning system, high pressure washing system, fire system.

Industrial liquid conveying: cooling and air conditioning systems, boiler feed and condensate systems, machine matching, acid and alkali.

Water Treatment: Industrial circulating system and processing system, environmental protection water treatment and infiltration analysis system, Ultrafiltration systems, reverse osmosis systems, distillation systems, separators, swimming pool

Irrigation: Agriculture irrigation and dewatering, sprinkler irrigation, drip irrigation.

3.Non-negative Pressure Building Water Supply Pump images

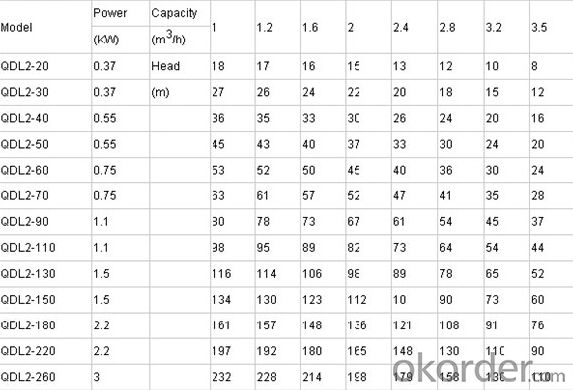

4.Non-negative Pressure Building Water Supply Pump Specification

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: Fire pump and shower pump flow head selection, high resolution.

- 3, larger than 25000, the minimum water consumption of indoor fire hydrant is 20L/s4, the minimum water consumption is the flow of a fire hydrant.

- Q: What is the pump lift voltage? And how to suppress the pumping voltage rise?

- The reverse voltage and torque electric torque instead, and the motor has strong braking torque, forcing the rotor quickly stopped, but usually AC-DC-AC converter is the main power AC/DC rectifier circuit is irreversible, and therefore can not return to the power grid, resulting in the main circuit of the capacitor voltage increases two that is called the pump voltage.

- Q: What's the pump? Where can I use it?

- Working principleIt transfers mechanical energy or other external energy of the prime mover to the liquid, increasing the energy of the liquid. Before the pump starts, the pump shell is filled with the liquid to be transported; after starting, the impeller is driven by the shaft to rotate at high speed, and the liquid between the blades must also rotate. Under the influence of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and obtains energy, and leaves the outer edge of the impeller at high speed to enter the volute pump shell. In the spiral case, the liquid slows down due to the gradual enlargement of the flow passage, and the part of kinetic energy is converted to static pressure, and finally flows into the exhaust pipe at higher pressure and is sent to the required place. When the liquid flows from the center of the impeller to the outer edge, a vacuum is formed at the center of the impeller. As the pressure at the upper level of the tank is greater than the pressure at the pump inlet, the liquid is continuously pressed into the impeller. Visible, as long as the impeller continues to rotate, the liquid will continue to be inhaled and discharged.

- Q: What does electromechanical vector pump mean?

- It is a close set of mechanical and microelectronic technology. It adopts dual control center mode to control, and has a new water pump with logic control center and IPC control center.

- Q: Does the reservoir water heater press the booster pump (high marks)?

- In addition, the water storage electric water heater has a safety valve is O.7MPa, before buying a booster pump, you can check the water inlet valve spring weakness, see the effect of water, barely even, then use it, do not buy.

- Q: Rules for operation of centrifugal pumps

- 3, start the pump, wait until the speed reaches the normal speed, slowly open the outlet valve, observe the ammeter at the same time, and control the current in the rated current range of the motor.4, the operation requires smooth operation of water pumps, no abnormal noise, no pressure fluctuations. The abnormal situation should be stopped in time.

- Q: What is a feed pump?

- Feeding the role of the pump is to make the injection pump inlet pressure, increase the injection pump inlet pipe flow rate, in order to ensure high pressure water injection pump has sufficient supply.

- Q: Why is the submersible pump tripped on an electrical switch?There is no electrical leakage protection, directly connected to the circuit breaker, and when the switch on, the circuit breaker jumpedI checked the line is good, the pump did not break down, is not the water pump?

- Submersible pump cable or motor insulation is damaged.3) motor water solution

- Q: No negative pressure water supply equipment, both the main pump and auxiliary pump, power is not the same, how to choose the control cabinet?

- 1) microcomputer frequency conversion control cabinet2) water pump unit3) current stabilizing compensator4) vacuum suppressor5) all kinds of pipe fittings, valves and so on

- Q: Attention should be paid to the use of pumps?

- 7 water pump and pipe interface must be sealed, because if there is debris access, then the pump will cause damage to the interior. 8 for the water pump bearing is also the focus of inspection, use up to check whether the bearings wear,

Send your message to us

Non-negative Pressure Building Water Supply Pump in Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches