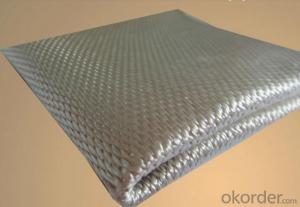

Vermiculite Coated Fiberglass Fabric for River Bank - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

No long-term creep : as a reinforcing material , with the ability to resist deformation under the load in the long-term creep resistance is extremely important, the glass fiber will not creep , to ensure that the products can long-term performance .

3.Application

ysical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

4.FAQ

good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

- Q: Can fiberglass fabric be used for making gaskets?

- Yes, fiberglass fabric can be used for making gaskets. Fiberglass fabric is known for its high strength and heat resistance, making it an ideal material for gaskets that need to withstand high temperatures and pressure. It can provide a reliable seal and is often used in applications where chemical resistance and durability are required, such as in automotive, aerospace, and industrial settings. Additionally, fiberglass fabric is lightweight and flexible, allowing for easy installation and versatility in various gasket designs.

- Q: Can fiberglass fabric be used for insulation in aerospace applications?

- Yes, fiberglass fabric can be used for insulation in aerospace applications. Fiberglass fabric is known for its excellent thermal insulation properties, making it an ideal choice for aerospace applications where temperature regulation is crucial. It is lightweight, flexible, and can withstand high temperatures, making it suitable for use in various aerospace components such as engine compartments, fuel tanks, and aircraft interiors. Additionally, fiberglass fabric is resistant to chemicals, moisture, and fire, providing an added layer of safety and protection in aerospace environments. Overall, fiberglass fabric is a reliable and widely used insulation material in aerospace applications due to its excellent thermal properties and durability.

- Q: Is fiberglass fabric resistant to pests and insects?

- Yes, fiberglass fabric is generally resistant to pests and insects. The nature of fiberglass, being made of woven glass fibers, makes it less appealing to pests and insects compared to other materials like cotton or wool. Fiberglass fabric is not a food source for pests, and its smooth and non-absorbent surface makes it less likely for insects to establish a habitat or lay eggs. However, it is important to note that while fiberglass fabric may be resistant to pests and insects, it is not completely immune. In rare cases, certain types of insects or pests may still be able to cause damage to fiberglass fabric, especially if the fabric is already compromised or damaged. Overall, fiberglass fabric is a good choice for those looking for a material that is generally resistant to pests and insects.

- Q: Can fiberglass fabric be used for reinforcement in 3D printing?

- Yes, fiberglass fabric can be used for reinforcement in 3D printing. Fiberglass fabric is a strong and lightweight material that can provide additional structural support to 3D printed objects. It can be used to reinforce certain areas of a print, such as corners or joints, to prevent cracking or breaking. By adding layers of fiberglass fabric within the 3D printed object, the overall strength and durability can be significantly improved. However, it is important to note that using fiberglass fabric in 3D printing may require specialized equipment and techniques to ensure proper adhesion and integration with the printed material.

- Q: Can fiberglass fabric be used for architectural applications?

- Certainly, architectural applications can make use of fiberglass fabric. This adaptable material presents several advantages for architectural projects. Its lightweight nature, flexibility, and exceptional tensile strength make it ideal for a range of applications, including roofing, cladding, and insulation. Moreover, fiberglass fabric's durability and longevity are enhanced by its resistance to fire, chemicals, and UV rays. Its ability to be effortlessly molded into intricate shapes further allows architects to conceive distinctive designs and structures. In conclusion, the manifold benefits and versatility of fiberglass fabric establish it as a favored option for architectural applications.

- Q: How is fiberglass fabric stored and transported?

- Fiberglass fabric is typically stored in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. It is often rolled onto large cardboard or plastic cores to prevent creasing or damage. When transported, it is usually packed in durable containers or wrapped in protective materials to ensure its safety and prevent any potential damage during transit.

- Q: How is fiberglass fabric used in the production of thermal blankets?

- Fiberglass fabric is used in the production of thermal blankets due to its excellent insulating properties. The fabric is woven with fine fiberglass strands, which create a heat-resistant barrier. This helps to trap and retain heat, making the thermal blanket highly effective in providing warmth and insulation. The fiberglass fabric also adds durability and strength to the blanket, making it long-lasting and suitable for various applications.

- Q: Can fiberglass fabric be used for reinforcement?

- Yes, fiberglass fabric can be used for reinforcement. It is commonly used in various industries such as construction, automotive, aerospace, and marine for reinforcing materials like composites, concrete, plastics, and even paper. The high strength, durability, and resistance to heat and chemicals make fiberglass fabric an ideal choice for reinforcement purposes.

- Q: How is fiberglass fabric used in the aerospace industry?

- Fiberglass fabric is commonly used in the aerospace industry for its lightweight and high-strength properties. It is used to reinforce various components such as aircraft wings, fuselage panels, and interior parts. The fabric is typically impregnated with resin and then molded or laminated to create strong, durable structures. Additionally, fiberglass fabric is also utilized in the production of heat shields and insulation materials to protect against extreme temperatures encountered during space travel.

- Q: How is fiberglass fabric used in the production of wind turbine blades?

- Fiberglass fabric is extensively used in the production of wind turbine blades due to its exceptional properties and advantages. The fabric is typically made from woven fiberglass filaments, which are lightweight, strong, and highly durable. One of the most significant uses of fiberglass fabric in wind turbine blades is as the main structural material. The fabric is typically layered and impregnated with a resin, such as epoxy, to form a composite material known as fiberglass-reinforced polymer (FRP). This FRP composite provides the required strength and stiffness to withstand the forces and stresses experienced by the blades while operating in the wind. The process of incorporating fiberglass fabric into wind turbine blades involves several steps. First, a mold is created in the shape of the blade using a positive model. Layers of fiberglass fabric are then carefully placed onto the mold, with each layer oriented in a specific direction to optimize the blade's mechanical properties. The fabric layers are impregnated with resin, ensuring that the entire structure is bonded together. This process is often repeated multiple times to increase the thickness and strength of the blade. The advantages of using fiberglass fabric in wind turbine blades are numerous. Firstly, the fabric's lightweight nature allows for the construction of longer and larger blades, enabling more efficient energy capture from the wind. Additionally, fiberglass fabric is highly resistant to corrosion, making it an ideal choice for outdoor applications, where the blades are constantly exposed to harsh environmental conditions. Furthermore, the inherent flexibility of fiberglass fabric allows the blades to bend and twist with the changing wind conditions, effectively reducing unnecessary stress and enhancing overall performance. The fabric is also resistant to fatigue, meaning that it can withstand repeated loading cycles without compromising its structural integrity. Overall, fiberglass fabric plays a crucial role in the production of wind turbine blades by providing the necessary strength, durability, and flexibility required for efficient and reliable energy generation. Its lightweight nature, corrosion resistance, and fatigue resistance make it an ideal material choice for constructing blades that can withstand the demanding operating conditions of wind turbines.

Send your message to us

Vermiculite Coated Fiberglass Fabric for River Bank - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords