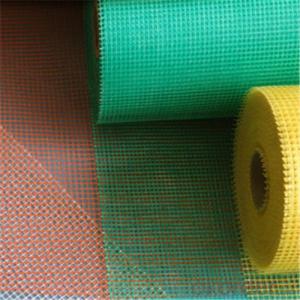

Fiberglass Lampshade Fabric YX-GF(SL) 105 Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Application: | Surface Treatment: | Width: | |||

| Weave Type: | Yarn Type: | Alkali Content: | |||

| Standing Temperature: | colour: | high temperature resistance: | |||

| breadth: | thickness: |

Packaging & Delivery

| Packaging Detail: | carton or plastic woven bags |

| Delivery Detail: | 10 work days |

Specifications

silica gel coated glass fiber cloth

thicknes:0.8mm-3.0mm

breadth:1000mm

high temperature resistance:350~450C

- Q: What are the disadvantages of using fiberglass fabric?

- One disadvantage of using fiberglass fabric is that it can be brittle and prone to cracking or breaking under certain conditions. Additionally, fiberglass fabric can be quite irritating to the skin and respiratory system, requiring the use of protective gear when working with it. Furthermore, fiberglass fabric is not as flexible as other materials, making it more challenging to work with in certain applications. Finally, fiberglass fabric can be more expensive compared to alternative fabric options, making it less cost-effective for certain projects.

- Q: Problems in making FRP models and models

- Method of making die at the end of the lowest cost, is artificial cutting and polishing, wood or other materials can have certain hardness and easy processing stuff, but it requires a very high skill, good feel, and often do it is not precise enough, but for ship model, basically is sufficient.

- Q: Are there any specific fire-resistant properties associated with fiberglass fabrics?

- Fiberglass fabrics possess specific fire-resistant qualities. Their fire resistance stems from the combination of glass fibers and resin used in their composition. The glass fibers in fiberglass fabrics exhibit no tendencies to burn, melt, or release toxic fumes when confronted with flames or intense heat. Consequently, fiberglass fabrics exhibit exceptional resistance to ignition and combustion. Moreover, these fabrics possess a high ignition temperature, necessitating higher temperatures for them to catch fire compared to other materials. Furthermore, their low heat conductivity ensures that they do not easily transfer heat, further augmenting their fire-resistant attributes. Consequently, fiberglass fabrics find widespread use in various applications that prioritize fire safety, including protective clothing, curtains, insulation materials, and the construction of fire-resistant structures.

- Q: Can fiberglass fabrics be used for reinforcement in building panels?

- Yes, fiberglass fabrics can be used for reinforcement in building panels. Fiberglass is a strong and lightweight material that is commonly used in construction due to its excellent strength-to-weight ratio and durability. When used as a reinforcement in building panels, fiberglass fabrics can provide additional structural integrity and enhance the overall strength of the panel. The fabric is typically embedded within a resin matrix, such as epoxy or polyester, to create a composite material that is strong, rigid, and resistant to various environmental factors. Additionally, fiberglass fabrics can be easily molded or shaped into complex forms, making them suitable for reinforcement in a variety of building panel applications.

- Q: Can fiberglass fabric be used for insulation in steam systems?

- Fiberglass fabric is indeed suitable as insulation in steam systems. Its exceptional thermal insulation properties and ability to withstand high temperatures make it a favored option. By effectively capturing the steam's heat, it prevents any loss of heat and enhances energy efficiency in the system. Moreover, fiberglass fabric's lightweight, flexible, and effortless installation process make it a convenient choice for insulating steam pipes and equipment. Its non-combustible nature also ensures safety in steam systems. All in all, fiberglass fabric is a dependable and efficient insulation material for steam systems.

- Q: Can fiberglass fabric be used as a heat shield?

- Yes, fiberglass fabric can be used as a heat shield. Fiberglass is a highly heat-resistant material commonly used in applications where thermal insulation is required. It has excellent fire resistance properties and can withstand high temperatures without melting or deforming. Fiberglass fabric is often used as a heat shield in various industries such as aerospace, automotive, and construction. It is lightweight, flexible, and can be easily molded or shaped to fit different surfaces. Additionally, fiberglass fabric is known for its low thermal conductivity, meaning it is an effective barrier for heat transfer. Overall, fiberglass fabric is a reliable choice as a heat shield due to its high heat resistance, versatility, and durability.

- Q: Can fiberglass fabric be used for reinforcement in swimming pools?

- Yes, fiberglass fabric can be used for reinforcement in swimming pools. It is a durable and lightweight material that is commonly used in the construction and maintenance of pools to provide added strength and support.

- Q: How does fiberglass fabric perform in water repellency?

- Fiberglass fabric is not inherently water repellent. However, it can be treated with various coatings or finishes to enhance its water repellency.

- Q: Can fiberglass fabric be used for reinforcement in chemical processing tanks?

- Indeed, fiberglass fabric proves to be a reliable option for reinforcement in chemical processing tanks. Its outstanding chemical resistance capabilities render it an optimal choice for scenarios where the tank is subject to various corrosive chemicals. Furthermore, its lightweight composition and remarkable strength contribute to fortifying the tank structure and enhancing its longevity. Moreover, fiberglass fabric exhibits versatility as it can readily adapt and conform to the specific design specifications of the tank, rendering it a multifaceted material for reinforcement in chemical processing tanks.

- Q: What is the cost range for fiberglass fabrics?

- The price range of fiberglass fabrics can differ based on a variety of factors, including the fabric's quality, weight, and width, as well as the supplier and any additional features or treatments applied to it. On average, fiberglass fabrics typically cost between $5 and $20 per yard. However, certain high-end or specialized fiberglass fabrics that possess specific properties or finishes can have higher price tags, sometimes exceeding $50 per yard or even more. It is important to remember that these prices are only approximate and may vary due to market conditions and individual suppliers. Furthermore, bulk orders or wholesale purchases might offer discounts, so it is advisable to directly contact suppliers for accurate pricing information.

Send your message to us

Fiberglass Lampshade Fabric YX-GF(SL) 105 Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords