R49 Fiberglass Insulation

R49 Fiberglass Insulation Related Searches

Fiberglass Thermal Insulation Fiberglass Wall Insulation Fiberglass Roll Insulation Fiberglass Blanket Insulation Fiberglass Insulation Blanket Resin Fiberglass Fiberglass Fabric Fiberglass Insulation Malaysia Fiberglass Temperature Resistance Fibreglass Batt Insulation Fiberglass Resin Fiberglass Roofing Tissue Car Fiberglass Fibreglass Resin Fiberglass Roving Fibreglass Fabric R13 Insulation Fiberglass Woven Fabric Fiberglass Yarn Fiberglass Woven S Glass Fiberglass Woven Fibreglass Fiberglass Price Per Kg Electrical Conductivity Of Fiberglass Direct Roving Fiberglass Fiberglass Distributors Fiberglass Properties Fiberglass Resin Bulk Fiberglass Sheets For Roofing Fiberglass DrywallR49 Fiberglass Insulation Supplier & Manufacturer from China

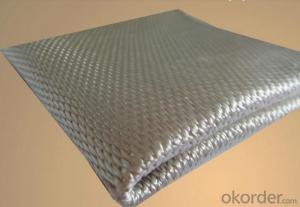

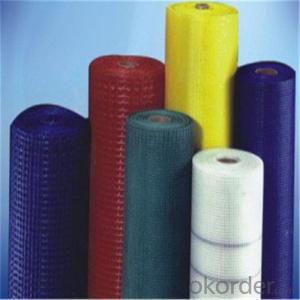

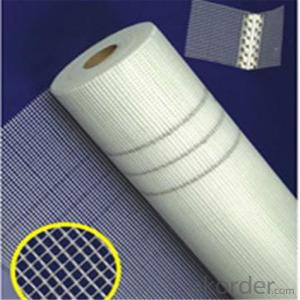

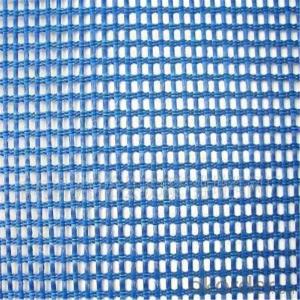

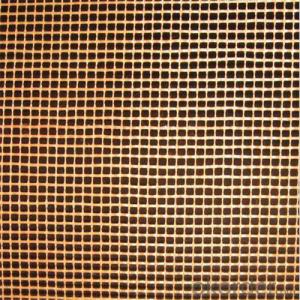

R49 Fiberglass Insulation is a high-quality insulation material designed to provide effective thermal and acoustic insulation in various applications. This product is made from durable fiberglass, which offers excellent resistance to heat, moisture, and other environmental factors, making it a popular choice for both residential and commercial projects. R49 Fiberglass Insulation is commonly used in walls, ceilings, and attics to reduce heat transfer and improve energy efficiency, as well as in noise-sensitive areas to dampen sound and create a more comfortable environment.R49 Fiberglass Insulation is widely applied in construction and renovation projects, where it plays a crucial role in enhancing the overall performance of buildings. It is particularly effective in maintaining indoor comfort levels by preventing heat loss during winter and heat gain during summer, thereby reducing energy consumption and costs. Additionally, its soundproofing capabilities make it an ideal solution for areas such as music studios, offices, and residential spaces where noise reduction is a priority. The product's versatility and effectiveness have made it a preferred choice for contractors, builders, and homeowners alike.

Okorder.com is a leading wholesale supplier of R49 Fiberglass Insulation, offering a vast inventory of this essential product to cater to the needs of various industries. As a reliable source for high-quality insulation materials, Okorder.com ensures that customers receive the best possible products at competitive prices. With a commitment to customer satisfaction and a focus on providing top-notch service, Okorder.com has established itself as a trusted supplier for R49 Fiberglass Insulation and other insulation solutions.

Hot Products