Velocity Slope Geogrids - Fiberglass Geogrid with CE Certification and Bitumen Coated

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with CE Certification and Bitumen Coated

Description Of Fiberglass Geogrid with CE Certification and Bitumen Coated:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with CE Certification and Bitumen Coated:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with CE Certification and Bitumen Coated:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with CE Certification and Bitumen Coated:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

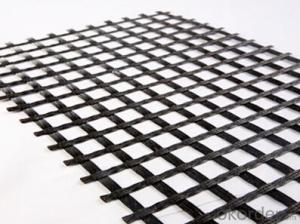

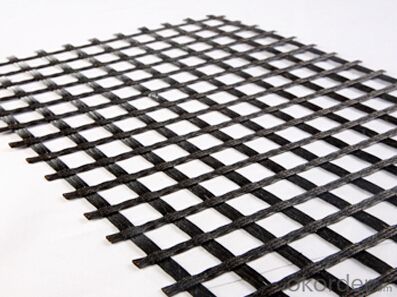

IMages of Fiberglass Geogrid with CE Certification and Bitumen Coated:

FAQ of Fiberglass Geogrid with CE Certification and Bitumen Coated:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are geogrids suitable for use in cold climates?

- Yes, geogrids are suitable for use in cold climates. Geogrids are made from materials that are resistant to temperature variations and have been designed to withstand the harsh conditions of cold climates. They provide excellent reinforcement and stabilization for soil and are commonly used in various applications such as road construction, retaining walls, and erosion control in cold regions.

- Q: Can geogrids be used in reinforcement of geosynthetic clay liners?

- Yes, geogrids can be used in the reinforcement of geosynthetic clay liners (GCLs). Geogrids are often used as a reinforcement material to enhance the tensile strength and stability of the GCLs, thereby improving their performance in applications such as slope stabilization, landfill liners, and erosion control. The geogrids are typically placed between layers of GCLs to provide additional support and prevent potential failure modes, such as shear sliding or lateral spreading.

- Q: Are geogrids resistant to hydrostatic pressure?

- Yes, geogrids are generally resistant to hydrostatic pressure.

- Q: What kind of circumstances need to shop geogrid

- Geogrid reinforced soil function, improve the integrity, equivalent to the concrete reinforcement. (corresponding to another material geotextile, play a major role in seepage prevention)

- Q: What are the general laying methods of Geogrid

- Along the longitudinal laying, U nail fixed joint part, 15 cm, with tie rods or connection

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- Different waterproof performance. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth and two membrane. Tensile, tearing resistance, bursting and other physical and mechanical properties of high index, the product has high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good performance of seepage control, etc..

- Q: How do geogrids improve the performance of geotextile sediment control tubes?

- Geogrids improve the performance of geotextile sediment control tubes by providing additional structural support and reinforcement. They help to prevent the tubes from collapsing or deforming under the weight of sediment, enhancing their overall stability and effectiveness in controlling erosion and sediment runoff.

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- Glass fiber mesh used in exterior wall, interior wall paint, mainly to prevent cracking, different materials at the junction of mortar plastering material hollowing. Local node reinforcement will also be used.

- Q: How much is the steel plastic geogrid?

- Steel plastic geogrid 50KN, 4.5 yuan per squareSteel plastic geogrid 60KN, 5 yuan per square

- Q: Glass fiber grating with large pulling force for Expressway

- The glass fiber geogrid is made of glass fiber alkali free roving as the main raw material, and the net structure material is made by certain knitting technology

Send your message to us

Velocity Slope Geogrids - Fiberglass Geogrid with CE Certification and Bitumen Coated

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords