Soil Stabilisation Geogrids - Fiberglass Geogrid Manufacturer with CE Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with CE Certificate,Welcome choose us!

Product Description

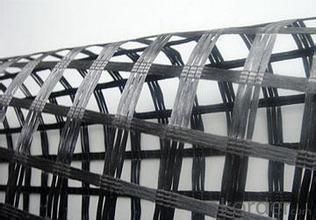

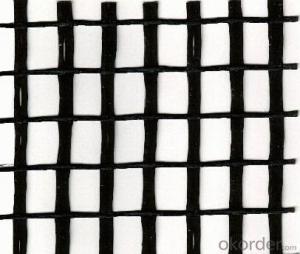

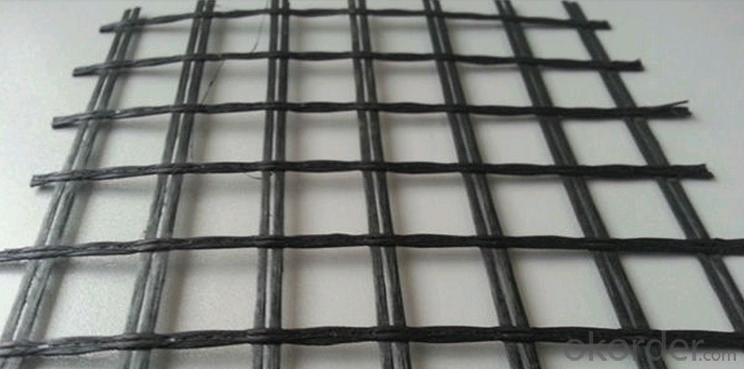

Bitumen coated fiberglass geogrid

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

| Property of Fiberglass Geogrid |

| Property | Test Method | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | |

| 30-30 | 40-40 | 50-50 | 60-60 | 70-70 | 80-80 | 90-90 | |||

| Ultimate tensile strength(1) (kN/m) | MD | EN ISO 10139 | 30 | 40 | 50 | 60 | 70 | 80 | 90 |

| CD | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| Elongation at maximum load (%) | MD | 3 | |||||||

| CD | 3 | ||||||||

| Approximate mesh size(mm) | 12.7mm×12.7mm 25.4mm×25.4mm 40mm×40mm | ||||||||

| Roll Width (m) | 1m-6m | ||||||||

| Roll Length(m) | 50m-200m | ||||||||

| Property | Test Method | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | |

| 100-100 | 120-120 | 130-130 | 150-150 | 160-160 | 170-170 | 180-180 | 200-200 | |||

| Ultimate tensile strength(1) (kN/m) | MD | EN ISO 10139 | 100 | 120 | 130 | 150 | 160 | 170 | 180 | 200 |

| CD | 100 | 120 | 130 | 150 | 160 | 170 | 180 | 200 | ||

| Elongation at maximum load (%) | MD | 3 | ||||||||

| CD | 3 | |||||||||

| Approximate mesh size(mm) | 12.7mm×12.7mm 25.4mm×25.4mm 40mm×40mm | |||||||||

| Roll Width (m) | 1m-6m | |||||||||

| Roll Length(m) | 50m-200m | |||||||||

Packaging & Delivery

| Packaging Details: | plastic pipe + black PE membrane |

| Delivery Detail: | one 40HQ within 15 days after receipt of T/T or L/C at sight |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- Such as artificial lakes, swimming pools, reservoirs and other projects, and geotextile is generally used in landscaping or highway pavement health

- Q: What is the GDL geogrid

- 2, to highlight the advantages of geogrid is deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project;3, the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, improve the service life of engineering.

- Q: Can geogrids be used in slope stabilization for railway embankments in permafrost regions?

- Yes, geogrids can be used in slope stabilization for railway embankments in permafrost regions. Geogrids provide reinforcement and stabilization to the soil, reducing the risk of slope failure and ensuring the stability of the embankment. They are particularly effective in permafrost regions where the frozen ground can be prone to thawing and subsidence. Geogrids improve the overall strength of the embankment, minimize soil movement, and help to maintain the integrity of the railway infrastructure in these challenging environments.

- Q: What are the advantages of using geogrids over traditional reinforcement methods?

- Geogrids offer several advantages over traditional reinforcement methods. Firstly, geogrids are lightweight and easy to handle, making installation quicker and more efficient. Secondly, they provide a higher tensile strength and better load distribution, resulting in improved stability and reduced deformation of the soil. Additionally, geogrids are resistant to chemical and biological degradation, ensuring their long-term performance. They are also cost-effective as they require less material and labor compared to traditional methods. Lastly, geogrids are versatile and can be used in various applications such as retaining walls, slopes, and roadways, offering a flexible solution for different engineering needs.

- Q: What is high strength geogrid

- Like fiberglass 150KN polyester 180KN unidirectional plastic 200KN

- Q: Can geogrids be used in retaining wall construction?

- Yes, geogrids can be used in retaining wall construction. Geogrids are commonly used as a reinforcement material in retaining walls to enhance stability, prevent soil erosion, and increase load-bearing capacity. They are typically installed horizontally within the soil layers of the retaining wall structure to distribute the forces exerted by the retained soil.

- Q: How do geogrids enhance the stability of landfill slopes?

- Geogrids enhance the stability of landfill slopes by providing reinforcement and increasing the strength of the soil. They are placed within the soil layers of the slope to distribute the applied loads and prevent excessive deformation. The geogrids act as a tension element, spreading the load across a wider area and reducing the risk of slope failure. Additionally, they improve the overall stability of the landfill slopes by controlling soil erosion, promoting drainage, and minimizing the potential for lateral movement.

- Q: Can geogrids be used in stormwater management systems?

- Yes, geogrids can be used in stormwater management systems. Geogrids are often utilized to reinforce and stabilize soil in stormwater management applications such as retaining walls, embankments, and erosion control measures. They can help improve the overall performance and longevity of stormwater management structures by enhancing soil stability and preventing erosion.

- Q: Are geogrids suitable for reinforcing landfill liners?

- Yes, geogrids are suitable for reinforcing landfill liners. These high-strength materials can enhance the stability and integrity of the liner system by providing additional reinforcement and preventing soil erosion. Geogrids also improve the overall performance and longevity of landfill liners, making them a reliable choice for reinforcing purposes.

- Q: Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are commonly used in geothermal installations to reinforce the ground and provide stability for underground piping systems. They help distribute the weight and thermal load, reducing the risk of ground settlement and ensuring efficient heat transfer.

Send your message to us

Soil Stabilisation Geogrids - Fiberglass Geogrid Manufacturer with CE Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords