Geocells Suppliers - Fiberglass Geogrid with CE Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

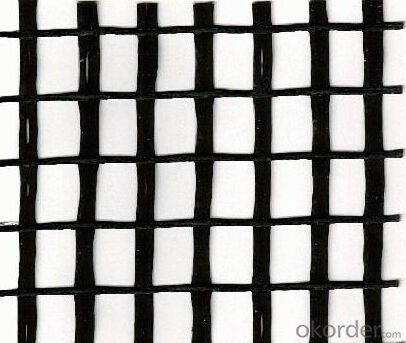

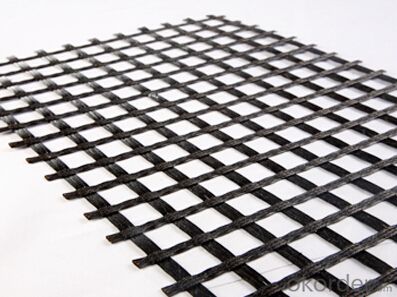

Fiberglass Geogrid Manufacturer with CE Certificate

Description Of Fiberglass Geogrid Manufacturer with CE Certificate:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Fiberglass Geogrid Manufacturer with CE Certificate:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer with CE Certificate:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer with CE Certificate:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

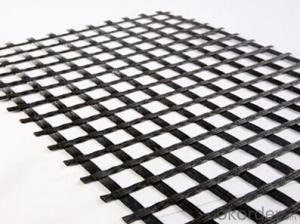

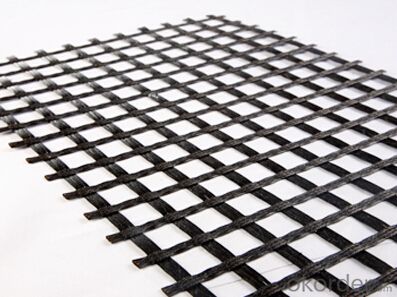

IMages of Fiberglass Geogrid Manufacturer with CE Certificate:

FAQ of Fiberglass Geogrid Manufacturer with CE Certificate:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are geogrids suitable for use in vegetated slopes?

- Yes, geogrids are suitable for use in vegetated slopes. They provide reinforcement and stability to the soil, preventing erosion and slope failure. The geogrids can be integrated with vegetation, allowing plants to grow through the grid and establish a strong root system, further enhancing slope stability.

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- Different waterproof performance. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth and two membrane. Tensile, tearing resistance, bursting and other physical and mechanical properties of high index, the product has high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good performance of seepage control, etc..

- Q: What factors should be considered when selecting a geogrid?

- When selecting a geogrid, several factors should be considered. Firstly, the intended application and the specific requirements of the project play a crucial role. Different geogrids are designed for various purposes such as soil stabilization, reinforcement, or erosion control. Secondly, the strength and durability of the geogrid are important considerations. The material composition, tensile strength, and resistance to environmental factors like UV radiation or chemicals should be evaluated. Additionally, the installation process and ease of handling the geogrid should be taken into account. Lastly, cost-effectiveness and the long-term performance of the geogrid should be considered to ensure an optimal selection.

- Q: What are the factors to consider when designing with geogrids for reinforced soil walls?

- When designing with geogrids for reinforced soil walls, there are several important factors to consider. Firstly, the type and strength of the geogrid material is crucial. The geogrid should have sufficient tensile strength and stiffness to effectively reinforce the soil and withstand the loads and stresses imposed on the wall. Secondly, the connection between the geogrid and the soil is critical. Proper anchoring and connection methods must be employed to ensure the geogrid remains securely in place and effectively distributes the loads throughout the reinforced soil structure. Additionally, the design should consider the wall height and slope angle, as these factors impact the stability and performance of the reinforced soil wall. The geogrid spacing and orientation must be determined based on these parameters to achieve the desired stability and load-bearing capacity. Other factors such as soil properties, water drainage, and environmental conditions should also be taken into account to ensure the long-term performance and durability of the reinforced soil wall. Overall, a comprehensive understanding of these factors is essential for successful design and construction with geogrids in reinforced soil walls.

- Q: What are the advantages of using geogrids in ground improvement for liquefaction mitigation?

- Geogrids offer several advantages when used in ground improvement for liquefaction mitigation. Firstly, geogrids provide increased shear strength to the soil, which helps to prevent liquefaction during seismic events. They enhance the stability and load-bearing capacity of the ground by effectively distributing loads and reducing settlements. Additionally, geogrids improve the overall performance of the soil by increasing its stiffness and reducing its compressibility. This ultimately leads to a more stable and resilient ground, reducing the risk of liquefaction-induced damage. Furthermore, geogrids are lightweight, easy to install, and cost-effective, making them a practical choice for ground improvement projects.

- Q: Do you need a production license for the production of geogrid?

- Generally not much

- Q: Geogrid tgsg50-50 what does it mean

- Hello ~TGSG is just a product code, referring to the two-way Plastic Geogrid

- Q: Are geogrids suitable for reinforcement of mechanically stabilized earth retaining walls?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized earth retaining walls. Geogrids are commonly used in these types of structures to provide additional strength and stability. They help distribute the forces and reduce the potential for wall failure, making them an effective choice for reinforcement in mechanically stabilized earth retaining walls.

- Q: Fiberglass grille and geogrid which use more

- Fiberglass geogrid is glass fiber rovings as the main raw material, the reticular structure material of the knitting process, for the protection of glass fiber and improve the overall performance, through a special coating treatment process and the formation of new excellent soil substrate.

- Q: Are geogrids suitable for use in mining tailings dams?

- Yes, geogrids are suitable for use in mining tailings dams. They are commonly used in such applications due to their high tensile strength, durability, and ability to reinforce soil and prevent erosion. Geogrids can enhance the stability and overall performance of tailings dams by providing structural support and preventing potential failures.

Send your message to us

Geocells Suppliers - Fiberglass Geogrid with CE Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords