Egrid App Biaxial Geogrids - Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforcement in Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

1. Specifications for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

Tensile Strength: 30KN*30KN-300KN*200KN

Mesh Size: 25.4*25.4mm

Width: 1-6m

Length: 50-300m

Elongation<4%

High quality asphalt coation

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

2. Technical Data for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

Specification | TGS-B-30-30 | TGS-B-50-50 | TGS-B-80-80 | TGS-B-100-100 | |

tensile strength (KN/m) | warp | 30 | 50 | 80 | 100 |

weft | 30 | 50 | 80 | 100 | |

Breaking elongation % | 3 max. | 3 max. | 3 max. | 3 max. | |

Aperture (mm) | 25*25 | 25*25 | 25*25 | 25*25 | |

Roll length (m) | 100 | 100 | 50 | 50 | |

rolls width (m) | 5.9 | 5.9 | 5.9 | 5.9 | |

3. Application for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

a. Used on asphalt pavement, bituminous cocrete pavement and cement pavement to prevent cracks from occurring and to prolon pavement service life.

b. Used as a basal reinforcement material for hillsides, reservoirs, harbours, ports, water channels and dams, seawalls, and similar site work.

c. Used to reinforce railroad subgrade on soft soil.

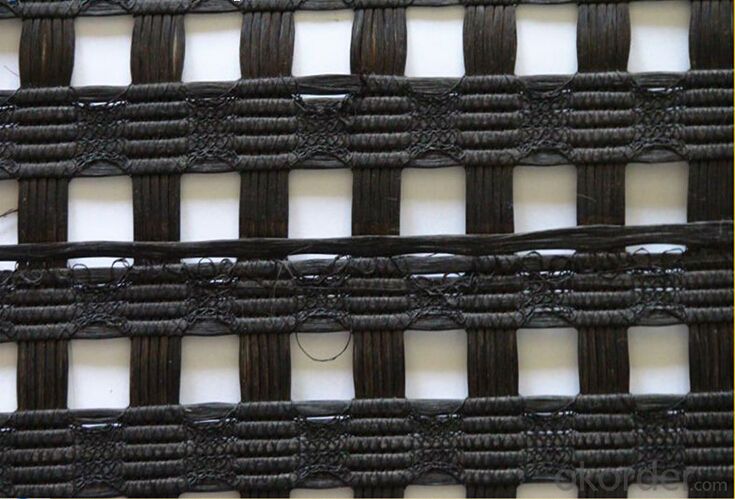

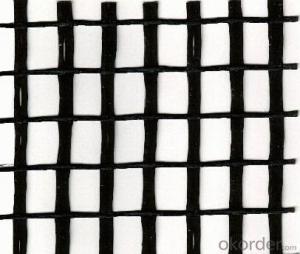

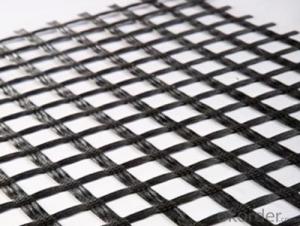

4. Photos for Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforce in Road Construction

FAQ:

1.What's your payment terms?

T/T , LC at right

2. What's your pacakge?

one roll with two woven bags

3. Can you provide free samples?

yes, but our express fees are usually on buyer's account

- Q: How to connect two-way geogrid

- Transverse 10cm overlap with plastic tape binding on the grid

- Q: Are geogrids resistant to chemicals and environmental degradation?

- Yes, geogrids are generally resistant to chemicals and environmental degradation. They are designed to withstand exposure to various chemicals, including acids, alkalis, and solvents, without significant degradation. Additionally, geogrids are typically manufactured using high-strength polymers that are resistant to UV radiation, biological degradation, and other environmental factors, ensuring their long-term durability and performance.

- Q: What are the types of Geogrid

- There are many types of geogrid is about tgsg / convex node tgsg / whole tgsg / glass fiber geogrid

- Q: What is the GDL geogrid

- 2, to highlight the advantages of geogrid is deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project;3, the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, improve the service life of engineering.

- Q: What are the applications of geogrids in civil engineering?

- Geogrids have numerous applications in civil engineering, primarily in soil stabilization and reinforcement. They are extensively used in road construction to improve the strength and stability of the subgrade and prevent rutting and cracking. Geogrids also find applications in retaining walls, embankments, and slopes, where they enhance the bearing capacity and reduce soil erosion. Additionally, they are utilized in landfills to enhance the stability of waste materials and in pavement overlays to reduce reflective cracking. Overall, geogrids play a crucial role in enhancing the durability and performance of various civil engineering structures.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing additional tensile strength and stability. These materials enhance the load-bearing capacity of the soil, prevent movement and settlement, and distribute the applied loads more evenly. Geogrids also minimize the potential for soil erosion and improve the overall durability and longevity of the reinforced structure.

- Q: Bidirectional geogrid 5 meters long side, short side of the 3 meters

- Bidirectional geogrid is a grid like

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth walls for bridge abutments?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth walls for bridge abutments. Geogrids are commonly used in these applications to enhance the stability and strength of the soil, thereby improving the overall performance and safety of the bridge abutment.

- Q: What are the advantages of using geogrids in flexible pavements?

- There are several advantages of using geogrids in flexible pavements. Firstly, geogrids provide increased pavement strength and stability by distributing stress and reinforcing the pavement layers. This helps to prevent cracking and rutting, especially in areas with heavy traffic loads. Secondly, geogrids improve the load-bearing capacity of the pavement, allowing for the use of thinner pavement layers. This reduces construction costs and materials, making it a cost-effective solution. Additionally, geogrids help to control and reduce pavement deformation caused by settlement, expansion, and contraction. This leads to longer pavement lifespan and reduced maintenance requirements. Lastly, geogrids enhance the overall resilience and durability of the pavement, making it more resistant to environmental factors such as temperature variations, moisture, and freeze-thaw cycles. Overall, the use of geogrids in flexible pavements offers numerous benefits in terms of increased strength, improved load-bearing capacity, reduced deformation, and enhanced durability, making it a preferred choice for pavement construction.

- Q: What are the different types of geogrids?

- There are several different types of geogrids, including biaxial geogrids, uniaxial geogrids, and triaxial geogrids. Biaxial geogrids have strength in two directions and are commonly used for soil stabilization and reinforcement. Uniaxial geogrids have strength in one direction and are often used for retaining walls and steep slopes. Triaxial geogrids have strength in three directions and are primarily used for load-bearing applications such as road construction and pavement reinforcement.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Egrid App Biaxial Geogrids - Bitumen Coated Fiberglass Geogrid with CE Certificate for Reinforcement in Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords