Spraying polyurethane foam for composite board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong China (Mainland) | Brand Name: | DHKCHEM | Panel Material: | Nonmetal |

| Type: | Polyurethane Sandwich Panels,Synthetic Resin and Plastics, Synthetic Rubbers | Apperance: | brown liquid |

Packaging & Delivery

| Packaging Detail: | 20gs/drum or 200kgs/drum |

| Delivery Detail: | within 7days after confirming order |

Specifications

1.Perfect flame resistance

2.Low thermal conductivity

Product Description

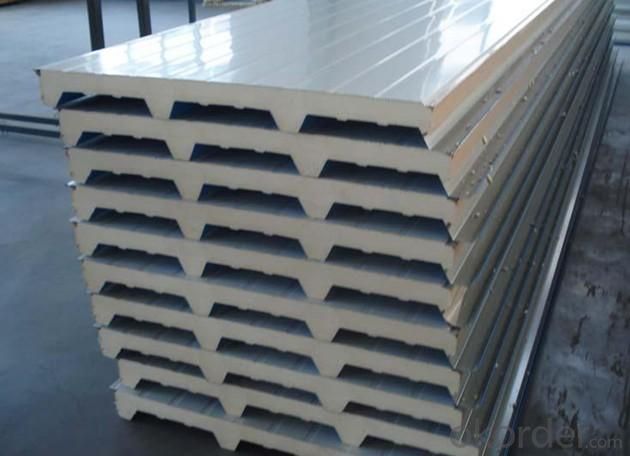

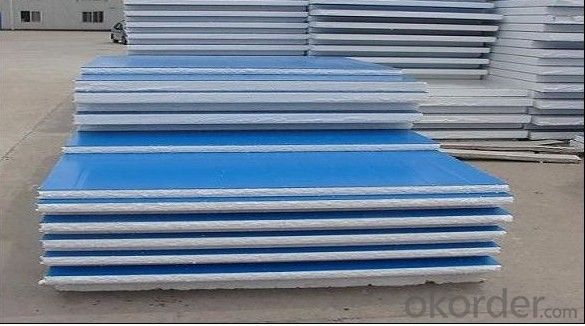

Polyurethane Foam Systems for Intermittent Boards/Sandwich DHK-204

1.Introduction

DHK204 blend polyols is a compound which consists of polyether polyols, surfactants, catalysts, foaming agent and flame retardant in a special ratio. The foam has good thermal insulation property, light in weight, high compression strength and flame retardance and other advantages. It is widely used to produce sandwich plates, corrugated plates etc, which applies to make cold stores, cabinets, portable shelters

and so on.

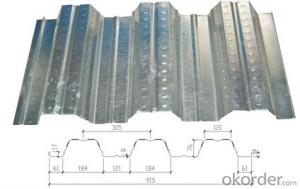

2.Technology and Reactivity (the exact value varies depending on processing conditions)

items | Manual mixing | High temperature machine |

Raw material temperature °C Moulding temperature °C Cream time s Gel time s Free density kg/m3 | 20-25 35-45 30-50 120-200 23-26 | 20-25 35-45 20-30 70-150 23-26 |

- Q: Buy plate three errors is what?

- At present, consumers themselves have many misunderstandings about the purchase of plates: ????"Trimming smooth and smooth plate must be good." This is not true. Perennial deal with the plate of a home improvement company boss said that the more such a plate of consumers more careful, trimming is generated when the machine sawing, good plate generally do not need "re-processing", often a lot of stubble child. But the quality of the plate because of its internal is empty, black core, so the processor will "deliberately dress up" it, in the trimming and then paste a "nice" wood, and polished smooth neat, to confuse the consumer , So you must not use this as a standard to measure what is good or bad. ????"3a is the best." Some readers reflect that they are doing the decoration in order to no problem, only selected marked "3a level" of the plate, the result is still a problem. In fact, the national standard is not "3a", but the business or business personal behavior, can not guarantee its quality. Currently on the market has not allowed the words, the detection of qualified wood will be marked "excellent goods", "first-class goods" and "qualified products." ????"The heavier the better plate". This view is absolutely incorrect, the insider to buy a look at the degree of drying, two see splicing. Good dryness of the plate is relatively light, and there will be no cracks, very smooth. For outsiders of consumers, the safest way is to reliable building materials market, buy some well-known brands of plates. In order to prevent some of the counterfeit products on the market, you must see whether the purchase of a national authority issued by the test report once the problem is also well documented.

- Q: How to do the corn stalks

- Process Technology Line: 1. Straw density plate: Air dry straw → impurity removal → cut off → wind selection (blown out of the heart) → cans → high pressure steam → spray → fine → spray → drying → pavement → preload → hot pressing → edge → cutting → packaging → finished product 2. Straw crushed plate (particleboard) Drying Straw → Cutting → Wind Selection → Recovering → Drying → Screening → (Surface Layer, Dust, Core Material) → Mixing → Pavement → Preloading → Hot Press → Edge → Cutting → Inspection → Packaging 3. Straw composite board Straw → Cutting → Steam Blasting → Mixing → Paving → Wood Veneer → Glue → Preloading, Hot Press → Side → Varnish → Sanding → Finished 4. New wall materials: Corn stover high grain straw → election → leaves → cut → pavement → irrigation → do the surface layer → veneer → sanding → finished In addition to the above processing, the straw can also be used for pulp making after steam blasting, which is about a third less expensive than traditional pulping methods and only one third of the traditional method. It is helpful to solve the problem of pulp gap caused by the forced cessation of small papermaking by the state. Fourth, the main technical key and expected to achieve the technical and economic indicators: 1. Main technical key: ① developed as low as possible, environmentally friendly, waterproof superior, infiltration of a good name of the glue. ② design and improvement of grading pavement. ③ steam blasting equipment selection and the determination of the main process parameters. ④ hot pressing and cold pressing process parameters adjustment. 2. Expected technical and economic indicators: ① adhesive; solid content: 60% -65% ??????????Free formaldehyde content: 0.2% or less ??????????Viscosity: coated with 4 cups: 30 ℃ 10-20 seconds (fiberboard) ?????????????????????????????????50-65 seconds (particle board)

- Q: Qianshan Wood Malacca plate how much money a piece

- Normal more than 200 to 300 have, too cheap do not easily believe that is likely to be fake, decoration with the plate can not careless, to prevent the use of poor quality sheet, affecting health, choose authentic, in order to simply identify genuine, each There are anti-counterfeit labels on the plate, you can go to the official website query verification.

- Q: What is the meaning of C in 13.5 * 1500 * C in plate specifications?

- In front of the thickness and width, C said length, according to need to determine.

- Q: It is good for plate of plate and plate of deer river

- Asia Asia Group, the first 10, Asia's first large Asia-based panel production of large Asian health board "Daya Group currently has nine production bases in China, the total annual production scale of nearly 300 million cubic meters / year", large As early as 2008, the sub-panel group started to implement the E0 grade MDF and developed a super-E0 board with limited formaldehyde release of less than 4mg / 100g according to customer requirements. In 2008 the company passed the US CARB certification. Most of the large Asian health board is the use of natural rubber, the use of natural rubber sheet of environmental protection index must be higher than other plates, and now large Asia-based panel group with reference to international mainstream standards, to develop a strict formaldehyde emission control standards, All grades require MDF and particleboard products. Qu Mei furniture, Maige furniture and many other enterprises are using the brand of E0-plate products.

- Q: How is the stone sheet transported?

- (2) the transportation of decorative stone sheet Handling and handling must comply with the following: (1) should be lightly loaded when handling, is strictly prohibited to roll, the vertical code must be placed on the back edge of the first landing. (2) stone sheet monolithic area of more than 0.25m2, all upright handling. Large products with lifting gear handling, the force edge edge must be pad. (3) wooden box packaging products, with lifting equipment loading and unloading, each lifting a box is appropriate. Cauline packaging products when handling, shall not pull grass rope. (4) loading code should be stored in accordance with the requirements of storage, transport required a smooth, non-collision.

- Q: Oude Sen board in the end where environmental protection?

- Germany Oude Sen board partners include Knightley, strong, Qu Mei, Oriental Parkson and Green Island. For the relationship between sheet metal and plate furniture, the sheet is only a carrier, plate furniture business should know how to tailor, to ensure the use of high-quality plate on the basis of the development of additional value-added products. It can be said that the plate is a product of good or bad basic protection, but it did not promote the entire furniture market capacity. ???? As the German plate brand, Odense has three advantages. First, the quality of raw materials is good. Germany has pine, beech and oak and other rich wood resources, the plate of soft and hard wood ratio of 70%: 30%. With wood and more plastic less, more environmentally friendly; plate light strength is good, grip nail strong and more durable; plate thickness uniformity, flatness is not easy to deformation. Second, the equipment is good. Advanced sheet metal manufacturing and processing equipment, to ensure the quality and stability of the product. Third, stick to the rules. Foreigners are relatively conservative way of doing things, the quality of sheet metal products and process requirements are also very strict, there is no room for discussion, as long as the failure to eliminate.

- Q: Plate Jianxiang E0 and ecological board which is good

- This is the concept of two issues, it is recommended that you choose Jianxiang sheet EO ecological board. Ecological board in the industry there are a variety of names, commonly known as a paint-free board and melamine board. The initial name is called melamine board, but because of China's dairy products pollution incident, and later was renamed, the industry collectively referred to as the paint-free board, also called the ecological board, but the ecological board is too general, because many of the eco-friendly sheet can also Called the ecological board, so easy to confuse. EO, E1 is the content of formaldehyde content of sheet metal standard, all kinds of sheet metal formaldehyde emission standards.

- Q: Q235 material, 2.5mm thickness of the plate, flanging R corner of the smallest can not be less than how much? Is a material thickness? This problem is applied to similar flanging situation? Do sheet metal peers please help

- The minimum radius of the bend is 0.3t in the direction perpendicular to the rolling pattern, 0.8t parallel to the rolling pattern, and the minimum radius is 0.5t when it is at an angle of 45 ° to the rolling direction.

- Q: What are the types of plates for office furniture?

- Particleboard Particleboard is made of wood scrap as the main raw material, and then infiltration of glue, additives made of thin plate. Pressing the press method can be divided into two categories: extruded particleboard, flat particleboard. The main advantage of this type of sheet is the price is extremely cheap. Its shortcomings are also very obvious: very poor intensity. Generally not suitable for the production of large or mechanical requirements of the furniture.

Send your message to us

Spraying polyurethane foam for composite board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords