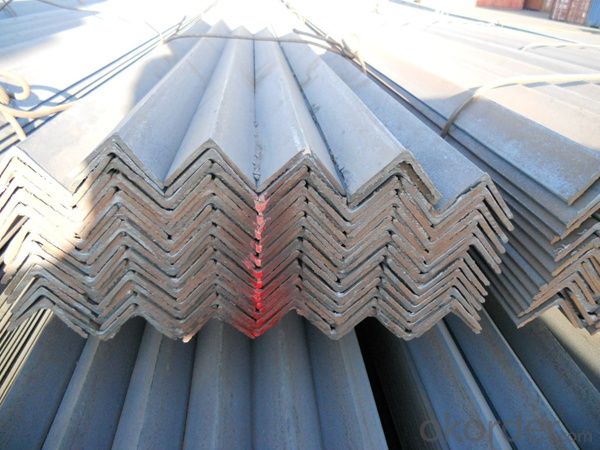

Hot Rolled Equal Angle Steel Bars for Construction, Structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Equal Angle Steel Bars for Construction, Structure at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Equal Angle Steel Bars for Construction, Structure are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

1. Supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers, etc

2. Prefabricated structure

3. Medium scale bridges

4. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

Hot Rolled Equal Angle Steel Bars for Construction, Structure are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel angles be used in sign support structures?

- Yes, steel angles can be used in sign support structures. Steel angles are commonly used in construction due to their high strength and durability. They provide excellent support and stability, making them suitable for a wide range of applications, including sign support structures. Steel angles can be easily welded or bolted together to create a sturdy framework for mounting signs. They also have a high load-bearing capacity, which is essential for ensuring the sign remains secure and stable, even in adverse weather conditions. Additionally, steel angles can be customized to suit specific design requirements, making them a versatile choice for sign support structures.

- Q: Can steel angles be used for supports in bridges?

- Yes, steel angles can be used for supports in bridges. Steel angles provide structural stability and strength, making them suitable for supporting heavy loads in bridge construction.

- Q: Can steel angles be used as handrails or guardrails?

- Yes, steel angles can be used as handrails or guardrails. They are commonly used in construction and provide sturdy support and protection when properly installed.

- Q: Can steel angles be used for foundation supports?

- Yes, steel angles can be used for foundation supports. Steel angles are commonly used in construction projects to provide structural support and stability. They have the ability to withstand heavy loads and provide durability, making them suitable for foundation supports. Steel angles can be easily connected to other structural components, such as beams or columns, to create a stable foundation system. Additionally, steel angles can be customized and fabricated to specific sizes and dimensions, ensuring that they meet the specific requirements of the foundation design.

- Q: How do steel angles contribute to the overall safety of a building?

- Steel angles contribute to the overall safety of a building by providing structural support and reinforcement. They are commonly used in construction to connect and strengthen various structural components, such as beams, columns, and trusses. Steel angles help distribute loads and resist forces, such as wind, earthquakes, and heavy loads, thereby enhancing the building's stability and resistance to collapse. Additionally, they can prevent lateral movement and deformation, ensuring the structural integrity of the building.

- Q: Can steel angles be used in seismic or high-wind areas?

- Yes, steel angles can be used in seismic or high-wind areas. Steel angles are commonly used in construction for their strength and durability. They provide structural support and can withstand seismic forces and high winds when properly designed and installed. The use of steel angles in these areas is often subject to specific building codes and regulations, which ensure that the structures are capable of withstanding the forces generated by earthquakes or strong winds. Engineering analysis and design considerations must be taken into account to ensure the appropriate size, configuration, and connection details of the steel angles in order to meet the required safety standards.

- Q: What are the different types of steel angles used in manufacturing industries?

- There are several different types of steel angles that are commonly used in manufacturing industries. These angles are utilized for various purposes and have different characteristics that make them suitable for specific applications. 1. Unequal Leg Angles: Unequal leg angles, also known as L-shaped angles, have one longer leg and one shorter leg. They are commonly used in construction and structural engineering due to their versatile nature. Unequal leg angles provide excellent strength and stability, making them ideal for supporting heavy loads and creating structural connections. 2. Equal Leg Angles: Equal leg angles, also known as L-shaped angles, have both legs of equal length. These angles are widely used in manufacturing industries for various purposes, including bracing, framing, and support structures. Equal leg angles offer good resistance to bending and provide stable connections in different applications. 3. Stainless Steel Angles: Stainless steel angles are made from corrosion-resistant steel alloy, primarily containing chromium. These angles are highly durable, resistant to rust, and have excellent strength properties. Stainless steel angles are commonly used in industries such as food processing, chemical processing, and marine manufacturing, where corrosion resistance is crucial. 4. Galvanized Steel Angles: Galvanized steel angles are coated with a layer of zinc to protect them from corrosion and rust. This zinc coating provides exceptional durability and longevity, making galvanized steel angles suitable for outdoor and exposed applications. They are commonly used in industries such as construction, agriculture, and transportation. 5. Rolled Steel Angles: Rolled steel angles are manufactured by rolling a steel plate or sheet into the desired shape. These angles offer excellent strength-to-weight ratio and can be produced in various sizes and thicknesses. Rolled steel angles are commonly used in construction, machinery, and fabrication industries for structural support and framing applications. 6. Slotted Steel Angles: Slotted steel angles have holes or slots along their length, providing flexibility for various fastening methods. These angles are often used in shelving systems, racking, and storage solutions, as they allow for easy adjustment and customization. Slotted steel angles offer versatility and convenience in manufacturing industries where quick assembly and reconfiguration are required. Overall, the different types of steel angles used in manufacturing industries offer a range of properties and advantages. The choice of angle depends on the specific application, requirements for strength, corrosion resistance, and other factors that ensure optimal performance and durability in the given application.

- Q: Are steel angles suitable for manufacturing structural beams?

- Yes, steel angles are suitable for manufacturing structural beams. Steel angles, also known as L-shaped structural steel, are commonly used in the construction industry to create structural beams due to their strength and versatility. Steel angles offer excellent load-bearing capabilities and are able to withstand heavy loads and forces, making them ideal for constructing beams that can support the weight of buildings, bridges, and other structures. Additionally, steel angles can be easily welded, bolted, or otherwise connected to form larger structural components, providing flexibility in design and construction. Overall, steel angles are a reliable and efficient choice for manufacturing structural beams.

- Q: Can steel angles be used as reinforcement in concrete structures?

- Yes, steel angles can be used as reinforcement in concrete structures. Steel angles are often used as L-shaped or angle-shaped bars that are embedded within the concrete to provide additional strength and support to the structure. These angles help to resist tensile forces and prevent cracking or failure of the concrete. They are commonly used in applications such as beams, columns, and walls to enhance the structural integrity and load-bearing capacity of the concrete elements. Additionally, steel angles can be easily welded or bolted together, making them a versatile and cost-effective choice for reinforcement in concrete structures.

- Q: Can steel angles be used in architectural or decorative applications?

- Yes, steel angles can be used in architectural or decorative applications. Steel angles are versatile structural elements that can be used to create various architectural and decorative features. Their angular shape allows for easy installation and provides structural stability. In architectural applications, steel angles can be used to create frames for windows, doors, and other openings. They can also be used as supports for beams, columns, and roofs. Steel angles can be incorporated into building facades to create unique and visually appealing designs. Additionally, they can be used to form staircases, handrails, and balustrades, adding both functionality and aesthetics to a building's design. In decorative applications, steel angles can be used to create ornamental features. They can be shaped and welded to form intricate patterns or designs, adding a touch of elegance and uniqueness to interior or exterior spaces. Steel angles can be used as decorative trim or edging, enhancing the visual appeal of architectural elements such as walls, ceilings, and furniture. They can also be used as decorative supports for shelves, countertops, and other surfaces. The use of steel angles in architectural and decorative applications offers several advantages. Steel is a strong and durable material, providing long-lasting support and stability. It is also resistant to corrosion, making it suitable for both indoor and outdoor use. Additionally, steel angles can be easily customized to meet specific design requirements, allowing for endless possibilities in architectural and decorative applications.

Send your message to us

Hot Rolled Equal Angle Steel Bars for Construction, Structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords