PP Fiber for Concrete Reinforcement Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

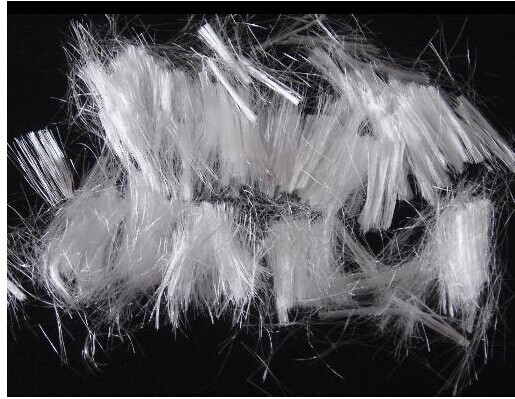

PP Fiber Introduction

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Features of PP Fiber for Concrete Reinforcement

pp fiber is also called engineering fiber, concrete fiber, anti-cracking fiber, synthetic fiber or plastic fiber.

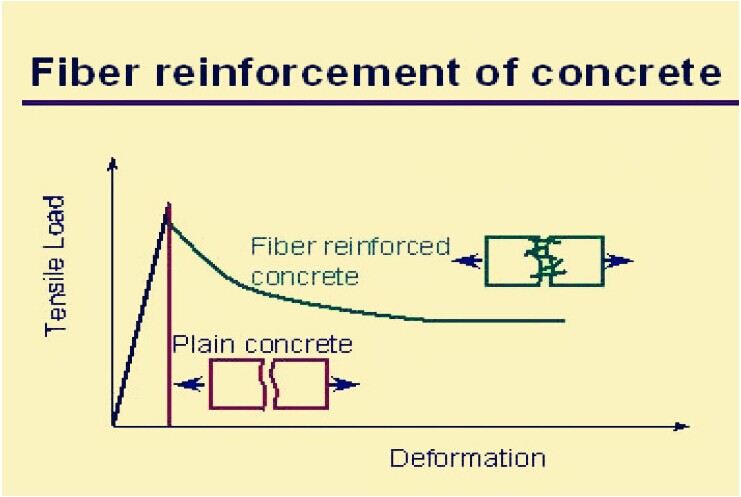

1).Prevention of the mortar’s contraction crack.

2).Improvement of the wall’s anti-shock and resistance to stripping.

3).Increasing of anti-permeability of wall.

4).Strengthen resistance to freezing and thawing.

5).Improve the ability of protection of reinforcement.

6).Prevent mud crack and crack propagation of mortar.

7).Substitute for steel mesh.

Technical Data of PP Fiber for Concrete Reinforcement

Name | 100%pp fiber |

Raw Material | Polypropylene/pp |

Type | Monofilament |

Fiber Dia | 10-45um |

Tensile Strength | ≥500Mpa |

Size | 6-48mm |

Crack Elongation | 15-25% |

Density | 0.91g/cm3 |

Melting Point | 160---170°C |

Resistance to Acid, Alkali | Strong |

Water Absorbency | No |

Package of PP Fiber for Concrete Reinforcement

1kg/plastic bag,20bags/pp woven bags

Product effect of PP Fiber for Concrete Reinforcement

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q: Can earthwork products be used for constructing terraced gardens?

- Yes, earthwork products can be used for constructing terraced gardens. Earthwork products such as retaining walls, terracing blocks, and geogrids can be utilized to create levels and stability in the garden. These products help to prevent erosion, shape the terrain, and provide structural support, making them ideal for constructing terraced gardens.

- Q: Are geosynthetics resistant to chemical degradation?

- Yes, geosynthetics are generally resistant to chemical degradation. They are designed with materials that have a high level of chemical resistance, allowing them to withstand exposure to various chemicals without significant degradation or deterioration.

- Q: How can geocells be used in slope reinforcement?

- Geocells can be used in slope reinforcement by providing stabilization and erosion control. These three-dimensional honeycomb-like structures are filled with soil or aggregate material, creating a strong and stable foundation. The interconnected cells prevent soil movement and sliding, effectively increasing the slope's resistance to erosion and landslides. Additionally, geocells can promote vegetation growth, further enhancing the slope's stability and sustainability.

- Q: How do earthwork products contribute to sustainable construction?

- Earthwork products, such as recycled aggregates and geosynthetics, play a crucial role in promoting sustainable construction practices. Firstly, the use of recycled aggregates reduces the need for extracting raw materials from quarries, thus minimizing environmental impact and conserving natural resources. Additionally, these products help divert construction and demolition waste from landfills, reducing waste generation and promoting circular economy principles. Moreover, geosynthetics, such as geotextiles and geomembranes, offer various environmental benefits. They can enhance soil stability, reducing the need for excavation and earthworks, which in turn minimizes disturbance to ecosystems and reduces carbon emissions associated with transportation and construction machinery. Geosynthetics also facilitate improved drainage and erosion control, helping to protect water quality and prevent soil erosion, further contributing to sustainable construction practices. In summary, earthwork products contribute to sustainable construction by conserving natural resources, reducing waste generation, minimizing carbon emissions, and protecting ecosystems and water quality. By incorporating these products into construction projects, we can achieve more environmentally friendly and sustainable outcomes.

- Q: Can geocells be used for load support in pavements?

- Yes, geocells can be used for load support in pavements. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) material. They are filled with compacted soil, aggregate, or concrete to create a stable base layer for pavements. The geocells provide confinement and prevent lateral spreading of the filler material, enhancing load-bearing capacity and reducing vertical deformation. This makes them an effective solution for load support in pavements, especially in areas with soft or weak subsoil conditions.

- Q: What are the advantages of using geotextile tubes for riverbank protection?

- There are several advantages of using geotextile tubes for riverbank protection. Firstly, geotextile tubes are highly effective in preventing erosion and stabilizing the riverbank. They provide a strong barrier against the forces of water, waves, and currents, thereby reducing the risk of bank collapse. Secondly, geotextile tubes are environmentally friendly as they are made from non-toxic materials that do not harm the ecosystem. Additionally, they can be filled with locally available materials such as sand, which makes them cost-effective compared to traditional methods. Lastly, geotextile tubes are easy to install and maintain, requiring minimal labor and resources. Overall, geotextile tubes offer a sustainable and efficient solution for riverbank protection.

- Q: Are earthwork products suitable for shoreline protection?

- Yes, earthwork products can be suitable for shoreline protection. They can be used to create berms, dunes, or other structures to help prevent erosion and protect the shoreline from wave action. These products offer stability and durability, making them an effective solution for shoreline protection in certain conditions.

- Q: What are the benefits of using concrete pipes in earthwork?

- There are several benefits of using concrete pipes in earthwork. Firstly, concrete pipes are extremely durable and can withstand heavy loads and harsh environmental conditions. They have a longer lifespan compared to other materials, reducing the need for frequent repairs or replacements. Additionally, concrete pipes are resistant to corrosion, making them ideal for use in underground drainage systems. They also provide excellent flow capacity, ensuring efficient transportation of fluids or materials. Lastly, concrete pipes are relatively cost-effective and easy to install, saving both time and money during construction projects.

- Q: Can earthwork products be used in slope reinforcement?

- Yes, earthwork products can be used in slope reinforcement. These products, such as geotextiles, geogrids, and erosion control blankets, are specifically designed to provide stability and prevent erosion in slopes. They can be installed to reinforce the soil, distribute loads, and enhance the overall performance and longevity of the slope.

- Q: What are the different design options available for earthwork products?

- Some of the different design options available for earthwork products include embankments, terraces, retaining walls, berms, and slope stabilization measures.

Send your message to us

PP Fiber for Concrete Reinforcement Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches