HDPE Geocomposite Drainage Geonet Liner Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

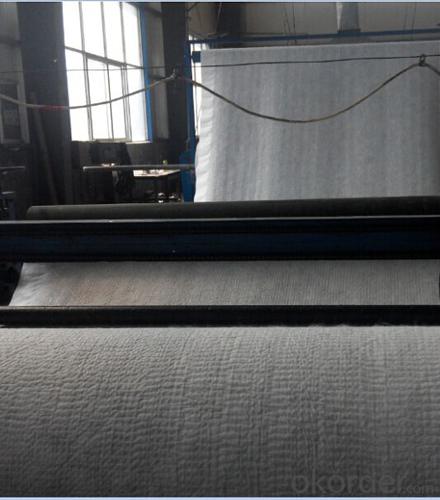

HDPE Geocomposite Drainage Geonet Liner Introduction

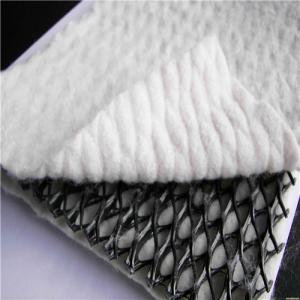

Drainage Geocomposites GCD is a high drainage capacity geocomposite, consisting of a flexible and high compressive strength HDPE Geogrid, covered by non woven-needle punched PP polypropylene geotextiles on one or both sides. Also available in PES polyester, HDPE high density polyethylene, coloured - recycled or waterproof one side.

Specification

Geonet thickness: 5-8mm; Width: 2-4m; Length as requested

Geotextile can be needle punched polyester geotextile, continuous filament PET nonwoven geotextile or Polypropylene nonwoven geotextile, and the unit weight normally 200g/m2.

NO | ITEM | UNITS | Value | ||||

1 | Unit weight | G/M2 | 750 | 1000 | 1300 | 1600 | |

2 | Thickness OV=20Kpa | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

3 | Hydraulic conductivity | m/s | KX10-4 | KX10-4 | KX10-3 | KX10-3 | |

4 | Elongation | % | <50< span=""> | <50< span=""> | <50< span=""> | <50< span=""> | |

5 | Tensile strength (core net work) | KN/m | 8 | 10 | 12 | 14 | |

6 | Geotextile | G/m2 | 200-200 | 200-200 | 200-200 | 200-200 | |

Features

1. Excellent drainage function, able to bear long time high pressure load

2. High tensile and shear strength

3. Able to protect its long time and stable hydraulic conductivity

4. Able to bear more than 2000kpa compression load, its anti-pressure capacity much higher than common drainage network

5. Corrosion resistant, acid and alkali resistant.

Application

Landfill drainage; Roadbed and road drainage; railway drainage; tunnel drainage; underground structure drainage; the retaining back wall drainage; garden and sports ground drainage.

Geonet is made of HDPE and anti-ultraviolet additives

1. Anti-aging, corrosion resistance

2. Highway and railway subgrade: effectively distribute load, improve its bearing capacity and stability and prolong service life

3. As layer of highway slope so that geonet can prevent landslide and protect water and soil, and beautify the environment

4. In reservoir and rive dykes to effectively prevent landslide; in the coastal engineering because of its soft good toughness, corrosion strong characteristic to buffer wave swept and corrosion

FAQ

1.How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 2-3 weeks. (Samples will be prepared within 3 days.)

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ. and we can provide you samples for quality inspection before the mass production.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

5. Can you produce according to customers' design?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: What are the advantages of using geomembranes for secondary containment?

- There are several advantages of using geomembranes for secondary containment. Firstly, geomembranes are highly durable and resistant to punctures, tears, and chemicals, ensuring a reliable barrier against leaks or spills. Secondly, they can be custom-designed to fit any shape or size of containment area, providing flexibility and versatility in their application. Additionally, geomembranes are relatively easy to install and maintain, saving time and costs compared to traditional containment methods. Lastly, they are environmentally friendly as they prevent the contamination of soil and groundwater, protecting the surrounding ecosystem.

- Q: What are the benefits of using geocells for channel protection?

- Using geocells for channel protection offers several benefits. Firstly, geocells provide excellent erosion control by confining and stabilizing soil, preventing it from being washed away by water flow. This helps to maintain the integrity and stability of channels, preventing erosion-related issues. Secondly, geocells promote vegetation growth. The interconnected cells create a stable structure that allows for the growth of vegetation, further enhancing erosion control. The plants' roots intertwine with the geocell structure, reinforcing the channel's stability. Thirdly, geocells are easy to install and require minimal maintenance. They are lightweight and flexible, making them quick and efficient to deploy. Once installed, they require little to no maintenance, reducing the overall costs and efforts associated with channel protection. Moreover, geocells are environmentally friendly. They are typically made from recyclable materials, reducing their ecological footprint. Additionally, their erosion control capabilities help to prevent sediment runoff, protecting water quality and the surrounding ecosystem. In summary, the benefits of using geocells for channel protection include erosion control, promotion of vegetation growth, ease of installation and maintenance, and environmental friendliness.

- Q: What are the advantages of using geotextile bags in coastal engineering projects?

- Geotextile bags offer several advantages in coastal engineering projects. Firstly, they provide effective erosion control by stabilizing the coastline and preventing the loss of sand or soil. Secondly, they are flexible and adaptable, allowing them to be used in various coastal environments and project requirements. Additionally, geotextile bags are environmentally friendly as they are made from biodegradable materials and do not harm marine life. They are also cost-effective compared to traditional methods, such as concrete structures, reducing project expenses. Lastly, their installation and maintenance are relatively simple, making them a practical choice for coastal engineering projects.

- Q: How do geocells provide erosion control on steep slopes?

- Geocells provide erosion control on steep slopes by confining and stabilizing the soil, preventing it from being washed away by water runoff. The interconnected cells create a structural matrix that reinforces the soil, reducing the velocity of water flow and minimizing erosion. Additionally, the geocells promote vegetation growth by retaining moisture and nutrients, further enhancing erosion control on steep slopes.

- Q: Can earthwork products be used for underground utility installation?

- Yes, earthwork products can be used for underground utility installation. These products, such as geotextiles and geosynthetics, are commonly used to provide stability, drainage, and erosion control in construction projects, including underground utility installations.

- Q: How do geosynthetic products contribute to soil erosion prevention in public parks?

- Geosynthetic products, such as geotextiles and geogrids, play a crucial role in preventing soil erosion in public parks. These materials act as a protective layer that stabilizes the soil, preventing it from being washed away by water or blown away by wind. Geotextiles, for example, are permeable fabrics that allow water to pass through while retaining soil particles, providing stability to slopes and preventing erosion. Geogrids, on the other hand, reinforce soil by providing additional tensile strength, distributing loads, and reducing soil movement. By using geosynthetic products in park design and construction, we can effectively mitigate soil erosion, preserve the park's aesthetic appeal, and ensure the long-term sustainability of these public spaces.

- Q: What are the safety considerations when using earthwork products?

- When using earthwork products, several safety considerations should be taken into account. Firstly, it is important to ensure proper training and supervision for workers who handle these products, as they can be heavy and may require specialized equipment for installation. Additionally, workers should be provided with personal protective equipment, such as hard hats, gloves, and safety glasses, to minimize the risk of injury. It is crucial to inspect the quality and stability of the earthwork products before usage to prevent any potential accidents or collapses. Adequate signage and barricades should also be placed around the work area to alert others and prevent unauthorized access. Regular maintenance and inspection of the products are essential to identify any wear and tear or potential hazards. Overall, prioritizing safety measures and following industry guidelines can help mitigate risks and ensure a safe working environment when using earthwork products.

- Q: What are the different types of geosynthetic drainage materials?

- There are several types of geosynthetic drainage materials, including geotextiles, geocomposites, geonets, geospacers, and geosynthetic clay liners (GCLs). Each of these materials has unique properties and functions, making them suitable for various drainage applications in civil engineering and environmental projects.

- Q: What are the key considerations when using geotextile mats for erosion control on golf courses?

- When using geotextile mats for erosion control on golf courses, there are several key considerations to keep in mind. Firstly, it is important to select the right type of geotextile mat based on the specific erosion control needs of the golf course. The mat should be able to withstand the anticipated flow of water, maintain its integrity under various weather conditions, and effectively prevent erosion. Secondly, proper installation is crucial. The mats should be placed securely and anchored appropriately to ensure they stay in place during heavy rainfall or irrigation. This may involve using stakes, pins, or other fastening methods to secure the mats to the ground. Additionally, maintenance and monitoring are essential for long-term effectiveness. Regular inspections should be conducted to check for any damage or signs of erosion. If any issues are identified, they should be addressed promptly to prevent further erosion. Lastly, it is important to consider the aesthetics of the geotextile mats. They should blend well with the surrounding landscape and not detract from the overall appearance of the golf course. Overall, by carefully considering the type of geotextile mat, proper installation, regular maintenance, and aesthetic integration, golf courses can effectively utilize geotextile mats for erosion control and maintain a visually appealing course.

- Q: What are the advantages of using geosynthetic erosion control blankets?

- Geosynthetic erosion control blankets offer several advantages, including providing immediate erosion protection, reducing sediment runoff, promoting vegetation growth, enhancing slope stability, and being cost-effective and easy to install.

Send your message to us

HDPE Geocomposite Drainage Geonet Liner Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords