PP Staple Fiber for Non-woven Geotextile Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 4000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Specification of PP Staple Fiber for non-woven Geotextile Use

1.Material | 100% polypropylene staple fiber |

2.Color | White,etc |

3.Fineness | 2.5D-25D |

4.Fiber Length | 51mm/64mm/76mm,etc |

5.Samples Time | within 3 days if available spec |

6.MOQ | 20 Metric tons |

7.Delivery time | within 15days against T/T deposit or L/C original |

8.Packing&Container loading

| option 1: Hydraulic pressure bale, 275kg/bale. |

option 2: as customer required. | |

20GP: 1*20GP can be loaded 9Tons. | |

40HQ: 1*40HQ can be loaded with 20 Tons. | |

9.Production Capacity | 500Mtons per month |

10.Payment term | L/C at sight, T/T 50% deposit, balance against B/L. |

Features

Synthetic Polypropylene Concrete Fiber, as the filling material of concrete, has the properties of good dispersibility, resistance to acid and alkali. The main functions are:

1. crack resistance;

2. Increase the seepage resistance of concrete;

3. Increase the freezing & thawing resistance of concrete;

4. Increase the impact resistance of concrete;

5. Increase the durability resistance of cncrete;

6. Increase the fire resistance of concrete.

End use of PP Staple Fiber for non-woven Geotextile Use

stuffing and packing of toy,pillow,sofa,seatcushion and leaning cushion;

thermalinsulation lining of shoes,gloves,cap and garment and so on;

raw material of spray finishing cotton,gel-free cotton,hardening cotton and non wovens;

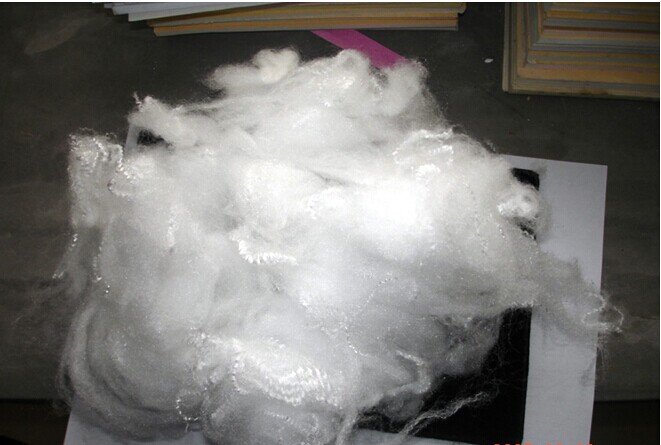

Product Photos of PP Staple Fiber for non-woven Geotextile Use

- Q: What are the benefits of using geogrids in slope stabilization?

- Geogrids offer several benefits in slope stabilization, including increased stability, improved load distribution, and enhanced erosion control. They provide reinforcement to the soil, reducing the risk of slope failure and preventing landslides. Geogrids also help distribute the load exerted on the slope, minimizing stress concentration and promoting even weight distribution. Additionally, they enhance erosion control by preventing soil erosion and promoting vegetation growth. Overall, geogrids are an effective and efficient solution for slope stabilization, ensuring long-term stability and safety.

- Q: How do geocells contribute to soil reinforcement?

- Geocells contribute to soil reinforcement by providing a strong and stable structure that confines and reinforces the soil. The interconnected cells are filled with soil, creating a three-dimensional grid system that improves load distribution, prevents soil erosion, and enhances overall stability. The geocell confinement restricts lateral movement of the soil particles, increasing its shear strength and resistance to deformation. This reinforcement technology is commonly used in various applications such as slope stabilization, retaining walls, and road construction to enhance the performance and longevity of the soil.

- Q: Which version of the material mechanics (author) is suitable for civil engineering this profession?

- Structural mechanics, "structural mechanics", "river dynamics", "geotechnical principles", "soil mechanics and environmental geology", "steel", "elasticity theory", "elastic theory" (upper and lower volumes) Structure of the basic principles "(second edition)

- Q: How are geocells used for load support in military installations?

- Geocells are used for load support in military installations by providing a stable and durable foundation for various structures, such as roads, landing strips, helipads, and storage areas. These cellular confinement systems help distribute and effectively manage heavy loads, ensuring improved load-bearing capacity and increased overall stability in military installations.

- Q: What are the different types of erosion control mats?

- There are several types of erosion control mats, including straw or hay mats, coconut fiber mats, jute mats, and synthetic erosion control mats made from materials such as polypropylene.

- Q: How do earthwork products help with erosion control?

- Earthwork products help with erosion control by providing physical barriers and stabilization measures that prevent soil erosion. These products, such as geotextiles, erosion control blankets, and sediment control devices, are designed to protect and reinforce soil surfaces, slopes, and channels. They help to reduce the velocity of water runoff, trap sediment, promote vegetation growth, and prevent the loss of topsoil. By creating a more stable and resilient environment, earthwork products effectively mitigate erosion and its negative impacts on land, water quality, and ecosystems.

- Q: Can geopipes be used for drainage systems?

- Yes, geopipes can be used for drainage systems. Geopipes are specifically designed to efficiently drain and transport water, making them an effective solution for drainage systems in various applications, including roads, sports fields, and agricultural areas. They are durable, lightweight, and have high flow capacity, making them an ideal choice for managing water runoff and preventing flooding.

- Q: What are the key considerations when using geotextile mats for erosion control on golf courses?

- Some key considerations when using geotextile mats for erosion control on golf courses include the material's durability and strength, proper installation techniques, selecting the right type of geotextile mat for the specific erosion control needs, ensuring proper drainage and water flow, and regular maintenance and inspection to ensure effectiveness. Additionally, considering environmental impact and compatibility with the golf course's aesthetics are also important factors to consider.

- Q: How do earthwork products contribute to groundwater recharge?

- Earthwork products, such as rain gardens, bioswales, and retention ponds, contribute to groundwater recharge by capturing and filtering stormwater runoff. These products are designed to slow down and absorb rainwater, allowing it to infiltrate into the ground instead of running off into nearby water bodies. This process helps replenish underground aquifers and maintain water levels, ultimately supporting groundwater recharge.

- Q: Can earthwork products be used in geotechnical engineering applications?

- Yes, earthwork products can be used in geotechnical engineering applications. Earthwork products, such as soil, aggregate, and geosynthetics, play a vital role in various geotechnical engineering projects. These products are used for construction of foundations, embankments, retaining walls, and other geotechnical structures. They provide stability, strength, and drainage capabilities to the engineered structures, making them an essential component in geotechnical engineering applications.

Send your message to us

PP Staple Fiber for Non-woven Geotextile Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 4000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords