Tri Geocomposite Drainage Net for Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tri Geocomposite Drainage Net for Slope Protection

Brief Description:

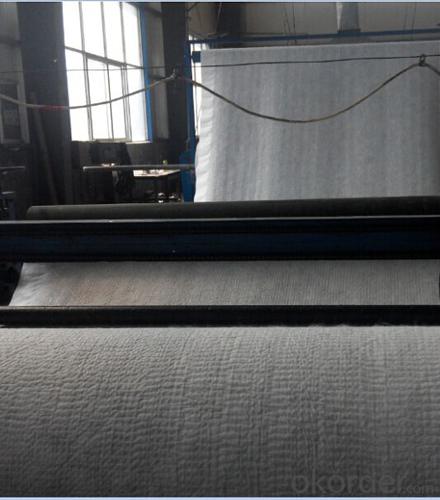

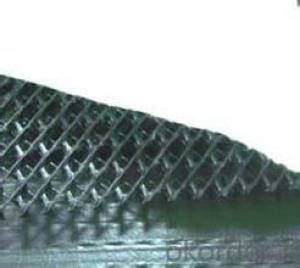

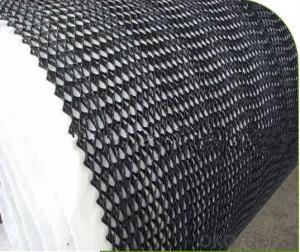

Geocomposite drainage is a drainage system consisting of three-dimensioanal high-density polyethylene

geonet, with high permeability, compressive strength and tensile strength, combined on one or both sides with

a nonwoven polypropylene geotextile.

Features:

Cost Effective - drainage nets can replace one or more feet of conventional aggregate drainage, increasing space within the landfill, allowing for additional revenue generation.

Versatility - drainage nets can be installed on steep slopes or against vertical walls where conventional drainage aggregates cannot be used.

Chemical Resistance - drainage nets exhibit the same chemical and biological resistance as the HDPE geomembrane.

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

1.What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

2.What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

3.What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions

Environment

Civil Works

Edification

- Q: How do geopipes help in underground infiltration systems?

- Geopipes play a vital role in underground infiltration systems by facilitating the efficient collection and distribution of stormwater runoff. They are designed to allow water to infiltrate through small perforations or porous materials, preventing surface flooding and reducing the strain on traditional drainage systems. Geopipes also help in filtering out contaminants and pollutants from the water, ensuring cleaner infiltration and protecting groundwater resources.

- Q: What are the benefits of using geosynthetic clay liners in landfill liners?

- Geosynthetic clay liners provide several benefits in landfill liners. Firstly, they have excellent hydraulic conductivity, which helps to effectively control the movement of liquids within the landfill, reducing the risk of contamination and groundwater pollution. Additionally, these liners have high chemical resistance, ensuring that hazardous substances do not penetrate the liner and contaminate the surrounding environment. Furthermore, geosynthetic clay liners offer enhanced stability and geotechnical properties, providing a reliable barrier to prevent the migration of waste materials. Lastly, they are relatively easy to install and cost-effective compared to traditional clay liners, making them a popular choice for landfill projects.

- Q: What are the advantages of using earthwork products in construction?

- There are several advantages of using earthwork products in construction. Firstly, earthwork products, such as soil, gravel, and sand, are readily available and easily sourced, making them cost-effective options for construction projects. Secondly, these materials can be easily compacted, providing a stable base for structures and improving their longevity. Additionally, earthwork products are often environmentally friendly, as they can be recycled and reused, reducing waste and minimizing the need for new materials. Lastly, these products can be easily manipulated and shaped, allowing for flexible and efficient construction processes.

- Q: Can earthwork products be used for culvert construction?

- Yes, earthwork products can be used for culvert construction. Earthwork products such as compacted soil, gravel, or crushed stone can be used to backfill around culverts, providing stability and support. Additionally, geotextiles can be used to reinforce the soil and prevent erosion, enhancing the durability and longevity of the culvert.

- Q: Can earthwork products be used in slope stabilization projects?

- Yes, earthwork products can be used in slope stabilization projects.

- Q: Can earthwork products be used for constructing outdoor fire pits?

- Yes, earthwork products can be used for constructing outdoor fire pits. Materials such as bricks, stones, and concrete blocks commonly used in earthwork can be assembled to create a sturdy and functional fire pit for outdoor use.

- Q: How can geocomposites be used in subsurface irrigation systems?

- Geocomposites can be used in subsurface irrigation systems by serving as a protective layer that prevents clogging of the irrigation pipes. They also aid in water distribution and filtration, improving the efficiency of the irrigation system. Additionally, geocomposites can help with soil moisture control and reduce water wastage, making them a valuable component in subsurface irrigation systems.

- Q: What is the purpose of using geotextile bags in streambank protection?

- The purpose of using geotextile bags in streambank protection is to prevent erosion and stabilize the streambank by acting as a barrier against the force of the water, while still allowing for proper drainage. The bags are filled with soil or other materials and placed strategically along the streambank to maintain its integrity and prevent further degradation.

- Q: Are earthwork products resistant to extreme temperature variations?

- Yes, earthwork products are generally resistant to extreme temperature variations due to their natural composition and ability to withstand thermal expansion and contraction.

- Q: How do earthwork products help in soil stabilization?

- Earthwork products, such as geotextiles and geosynthetics, play a crucial role in soil stabilization. These materials are designed to improve the stability and integrity of soil, preventing soil erosion and enhancing its load-bearing capacity. By providing reinforcement and erosion control, earthwork products help to distribute and dissipate the forces exerted on the soil, reducing the risk of slope failure and ensuring long-term stability. They also promote the filtration and drainage of water, preventing the accumulation of excess moisture that can weaken the soil. Overall, earthwork products are essential in creating a strong and durable foundation for various construction projects and in preserving the integrity of natural landscapes.

Send your message to us

Tri Geocomposite Drainage Net for Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords