Tri HDPE Geocomposite Drainage for Slope Protection Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

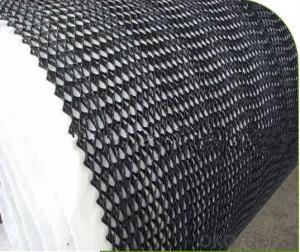

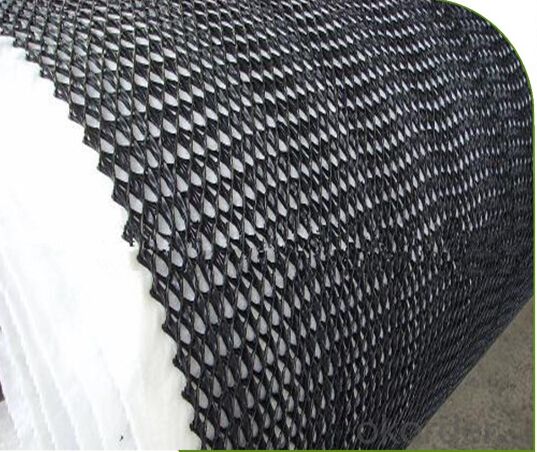

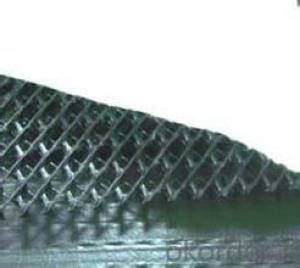

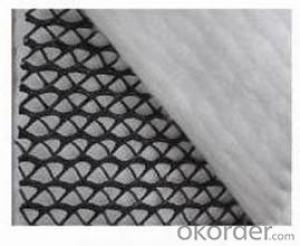

Tri HDPE Geocomposite Drainage for Slope Protection

Description :

Drainage Geocomposites GCD is a high drainage capacity geocomposite, consisting of a flexible and high compressive strength HDPE Geogrid, covered by non woven-needle punched PP polypropylene geotextiles on one or both sides. Also available in PES polyester, HDPE high density polyethylene, coloured - recycled or waterproof one side.

This structure provides for high flow rates for the life of a drainage structure, not just for few hours. Therefore TENAX TENDRAIN are triplanar geocomposites engineered for long term drainage in waste containment application characterized by the following

Ability of the drainage structure to maintain high long term in-plane flow;

Ability of the drainage structure to withstand long term compressive loads;

Ability of the drainage structure to provide adequate shear stability.

Application:

Water Lagoons

Lagooning and Water Treatment Tanks,

Reservoirs, Liquid

Waste Ornamental Ponds,

Golf Courses

Drainage and Filtration

Landfill CappingTailing ponds,

Leach miningVertical Barriers

Erosion ControlTunnels

Linear and Surface Works

Consolidation of Margins Building – Parking:

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

FAQ

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q: Can earthwork products be used for constructing terraced gardens?

- Yes, earthwork products can be used for constructing terraced gardens. Earthwork products such as retaining walls, terracing blocks, and geogrids can be utilized to create levels and stability in the garden. These products help to prevent erosion, shape the terrain, and provide structural support, making them ideal for constructing terraced gardens.

- Q: Can geocells be used for load support in parking areas?

- Yes, geocells can be used for load support in parking areas. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE) that can be filled with compacted materials such as soil, sand, or gravel. When installed and filled, geocells provide a strong and stable base for parking areas, distributing the load and preventing the settling of the surface. This helps to increase the load-bearing capacity and durability of the parking area, making it suitable for heavy vehicle traffic.

- Q: Civil engineering expertise which to master the technology (specific point of speaking)

- Civil engineering is the construction of various types of engineering facilities of science and technology collectively. It refers to the technical activities of the materials, equipment and facilities carried out by survey, design, construction, maintenance and repair; also refers to the object of construction, that is built on the ground or underground, land or water, directly or indirectly for human life Construction, military, scientific research services such as housing, roads, railways, transport pipelines, tunnels, bridges, canals, dams, ports, power stations, airports, offshore platforms, water supply and drainage and protection works The material basis of the facility is land, building materials, construction equipment and construction machinery. With these material conditions, economic and convenient to build both to meet people's requirements and aesthetic requirements, but also safe to withstand the load of various engineering facilities, civil engineering disciplines is the starting point and destination

- Q: What are the advantages of using geosynthetic materials in airport runway construction?

- There are several advantages of using geosynthetic materials in airport runway construction. Firstly, geosynthetics provide increased strength and stability to the runway, enhancing its overall performance and durability. These materials also offer excellent resistance to environmental factors such as erosion, frost, and water penetration, ensuring the longevity of the runway. Additionally, geosynthetics are lightweight and easy to install, saving time and labor costs during construction. Moreover, their use can lead to reduced maintenance requirements and increased safety for aircraft operations. Overall, geosynthetic materials contribute to the efficient and long-lasting construction of airport runways.

- Q: What are the cost implications of using earthwork products?

- The cost implications of using earthwork products can vary depending on factors such as the type and quantity of products needed, the location of the project, and the specific requirements of the construction or landscaping project. Generally, earthwork products can be more cost-effective compared to traditional construction materials, as they are often readily available and require minimal processing. Additionally, using earthwork products can reduce the need for extensive excavation and can contribute to environmental sustainability. However, it is important to consider transportation costs, installation expenses, and potential maintenance requirements when assessing the overall cost implications of using earthwork products.

- Q: How do geotextile tubes help in marine construction?

- Geotextile tubes are used in marine construction to provide effective erosion control and shoreline protection. These tubes are filled with sand or slurry and then placed in strategic locations to create barriers that prevent erosion and maintain stability. The geotextile fabric of the tubes allows water to pass through while retaining the fill material, ensuring that the construction remains intact even in high-energy marine environments. Additionally, these tubes can be easily installed, removed, and reused, making them a cost-effective and sustainable solution for marine construction projects.

- Q: What are the different types of geotextile bags available for erosion control?

- There are several different types of geotextile bags available for erosion control, including sandbags, coir logs, and geotextile tubes.

- Q: How are geosynthetic clay liners used in mining applications?

- Geosynthetic clay liners (GCLs) are used in mining applications to provide an impermeable barrier and prevent the leakage of liquids and contaminants from tailings ponds or waste storage areas. They are placed beneath the liner system to enhance the overall sealing capacity and minimize environmental risks associated with mining operations. GCLs are highly effective due to their ability to swell and self-seal when in contact with water, providing an additional layer of protection against leaks and seepage.

- Q: How are geosynthetic materials used in mining and oilfield applications?

- Geosynthetic materials are extensively used in mining and oilfield applications for various purposes. In mining, these materials are commonly employed for lining tailings storage facilities, heap leach pads, and ponds to prevent seepage and contamination of soil and water sources. They also serve as a barrier to control the movement of fluids and gases in underground mining operations. Additionally, geosynthetics are used in reinforcing mine access roads and stabilizing slopes to enhance safety and reduce erosion. In oilfield applications, these materials are utilized in constructing containment systems for oil and gas storage tanks, as well as lining ponds and impoundments to prevent leakage and protect the environment. They also play a crucial role in reinforcing drilling pads and stabilizing the ground during drilling operations. Overall, geosynthetics contribute significantly to improving the efficiency, sustainability, and environmental performance of mining and oilfield activities.

- Q: How do geotextile mats help with slope stabilization?

- Geotextile mats help with slope stabilization by providing reinforcement and erosion control. The mats are placed on unstable slopes to prevent soil erosion, retain soil particles, and distribute loads. They help to increase soil stability, promote vegetation growth, and reduce the risk of landslides.

Send your message to us

Tri HDPE Geocomposite Drainage for Slope Protection Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords