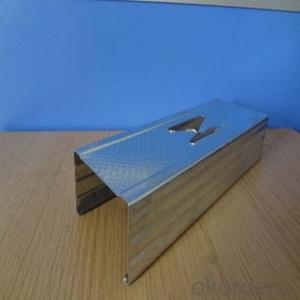

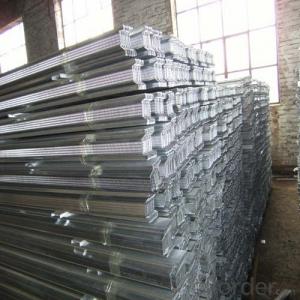

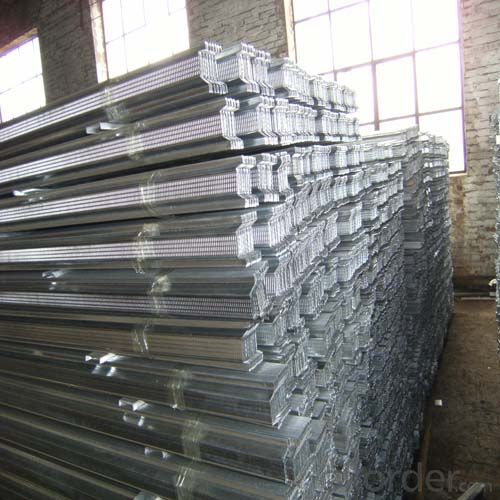

Ceiling Profile - Track of Light Steel Track of Light Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

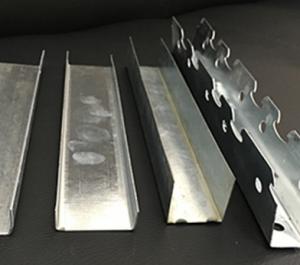

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

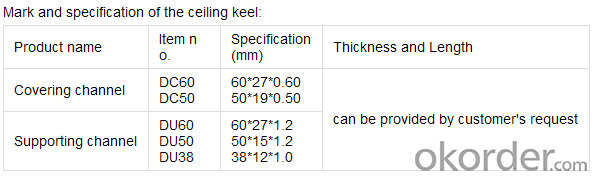

Product Specifications:

Images:

- Q: I am a novice . The How the keel is fixed on the ceiling of the hairy house. The Also gypsum board ceiling gypsum board is how to install on the keel I think: it will not fall? Is it to take nails or what glue up? What is the use of the boom (the ceiling will seem to use ..)

- Now the ceiling is generally light steel keel gypsum board ceiling. First of all, the hanging wire with the expansion of silk fixed on the ceiling hanging under a hanging piece is fixed on the main dragon. There is a buckle on the main dragon is stuck in the vice dragon. And then the gypsum board is used by the self-Gong Luo Luo on the vice dragon. Under normal circumstances as long as the operation in accordance with the norms do not have to fall off. Please rest assured that the landlord.

- Q: Why the ceiling keel

- Ceiling keel is what we often see the ceiling, especially the shape of the ceiling, are made of keel frame, and then covered with gypsum board made. Ceiling keel is made of light steel, for the ceiling of the main material, it is connected with the floor through the screw, used to fix the ceiling or objects.

- Q: Light steel keel ceiling good or wood keel good? Residential. I want to use light steel keel, but the designer said the reasons for modeling, light steel

- Now the basic use of keel less we do are to use light keel to do

- Q: Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel thickness has nothing to do with the height of the ceiling, and the span of the relationship between the ceiling, span, light steel keel thickness is slightly thicker.

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Wood keel, this wood keel is generally finished, bought can be used.

- Q: Ceiling 3 meters long light steel keel how much money one

- 4 to 5 quick money one meter

- Q: Ordinary light steel keel gypsum board ceiling budget sets which quota

- Ordinary flattened around with a light bulb, then 120 yuan per square meter Shaped 180 yuan per square meter Below this price you can not make money

- Q: Light steel keel ceiling crack repair several times is always cracked Guiqiu expert guidance

- There are problems, clawed look, is the keel of the re-reinforcement of the keel.

- Q: Light steel keel gypsum board ceiling hanging cut short can be connected to you

- One can pick up, buy a place to have a set of reed, about three centimeters. If you hang the tendons shorter than five centimeters recommended more short points up and down regulation.

- Q: Light steel keel gypsum board ceiling artificial materials about how much money a square meter

- Light steel keel ceiling material costs about 40. Keel 'gypsum board GB and non-standard price gap, depending on your choice. Labor costs flat about 35, modeling top 50-60 a square, depending on the specific complexity.

Send your message to us

Ceiling Profile - Track of Light Steel Track of Light Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches