Light Steel Ceiling Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

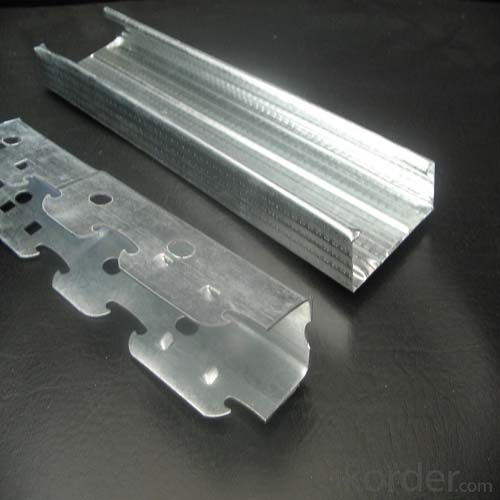

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

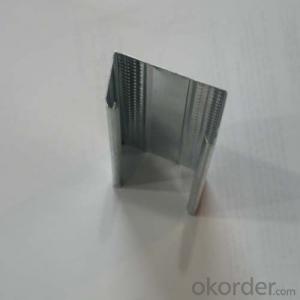

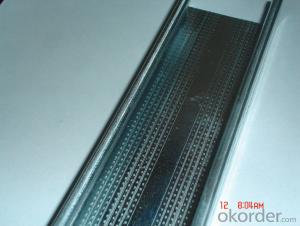

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

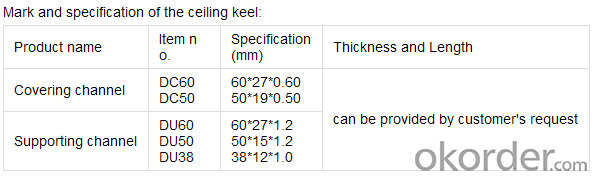

Product Specifications:

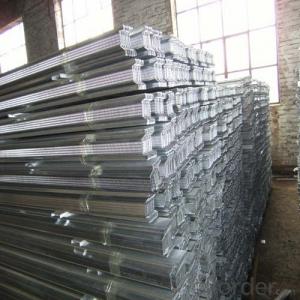

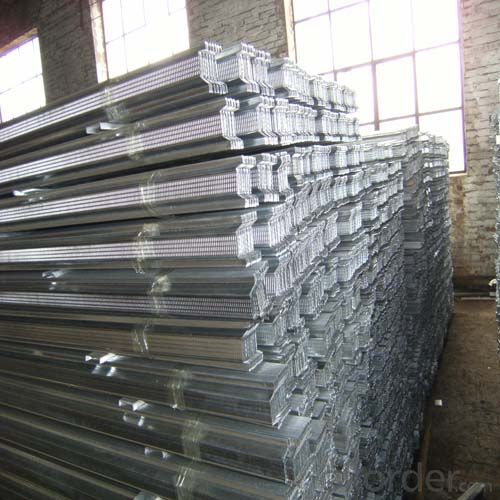

Images:

- Q: What kind of thickness of the light steel keel there is no specification?

- I think the real construction of the main situation is to see the cost requirements, under normal circumstances with 0.7-0.8 centimeters on the

- Q: Light steel keel ceiling screw must be installed vertically? There are pictures.

- As far as possible vertical, but in the adjustment process, there are still some skewed points.

- Q: What is the light steel keel?

- Light steel (paint) keel, is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction, etc., by the user and the design unit widely used. Light steel keel and paint keel is the difference between the general light steel keel is not painted surface treatment, making coating (galvanized), and paint keel surface made paint, generally divided into black and white, a few according to the design requirements baked into other colors, Mainly because most of the paint keel used in the Ming keel, paint is to ensure that the exposed part of the rust does not affect the appearance.

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- That depends on whether you are hanging flat or modeling top friends. See you want to hang double gypsum board, then I will tell you according to the price of flat top, package package material monolithic gypsum board ceiling 80 yuan / square or so, the wages of each place is different, plus a layer of plaster Board 20 dollars / square to the top, because a gypsum board is 2.88 square feet, the price is twenty or thirty dollars, the other to send you a little advice: ceiling with a screw must use 8-10mm, can not use 6mm

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Plastic buckle, it should be wooden keel, is the wooden side. If it is aluminum buckle, it should be light steel keel.

- Q: Light steel keel second ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling.

- Q: Light steel keel ceiling crack repair several times is always cracked Guiqiu expert guidance

- It is necessary to reinforce the keel and then seal the gypsum board. It is necessary to reinforce the keel and then seal it. If the exclusion of words to see if it is not gypsum board patchwork at the crack is the case First after the end of the crack more than put some time to stabilize the first shovel the surface of the putty layer and then putty powder on the cracks to do a little fill In the purchase of good cloth cut into a width of about 10CM strip with construction glue attached to the cracks in the dry after the coating can be This prevents the gypsum board from repeatedly cracking

- Q: Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated ceiling to be installed naturally nothing to ceiling accessories - keel. So, the ceiling keel on the ceiling plays a clear support, fixed role. Wood keel ceiling is good or light steel keel ceiling is better? It has a fire and rust anti-aging and other characteristics, but also in the construction of convenient, decorative effect is also very good. Light steel keel is relatively heavy, a long time more or less there will be sagging tendencies. Advantages and Disadvantages of Integrating Ceiling with Wood keel and Light Steel Now the light steel keel generally have been treated with paint, moisture, waterproof performance trustworthy, with a lot of performance. The wood keel light, easy to install and the price is relatively low, but there are some children defect. Wood keel because the main body is wood, it is easy to burn and corrosion, easy to mold in the wet bathroom, which the whole ceiling will cause a great impact. Of course, now a lot of wood keel have done anti-corrosion treatment, but also the surface of the wooden keel is also painted fire protection materials. This greatly improved the role of wood keel. In general, the wood keel ceiling or light steel keel ceiling is good, they have their own advantages, in fact, now with the development of society, integrated ceiling are more light steel keel.

- Q: Will the light steel keel ceiling be deformed?

- Generally not Please adopt If you acknowledge my answer, please accept it in time, ~ If you acknowledge my answer, please click on the "Accept Satisfactory Answer" button ~ ~ Mobile phone questions friends in the upper right corner of the client evaluation point [satisfaction] can be. ~ Your adoption is the driving force of my progress ~ ~ O (∩ _ ∩) O, remember praise and adoption, help each other

- Q: Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- When the hanging length of more than 1.5m should be set anti-support, reverse support is in the case of normal boom, from the lower end of the boom oblique ceiling installation to connect a rod, rod to have a certain stiffness, and the boom to form a Solid triangular. To prevent the ceiling in the air pressure when the upward deformation, the formation of dome, causing damage to the ceiling. The number of anti-support should be set according to the construction plan.

Send your message to us

Light Steel Ceiling Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords