ISO 9001 Certified Ceiling Profile Drywall Metal Studs and Tracks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

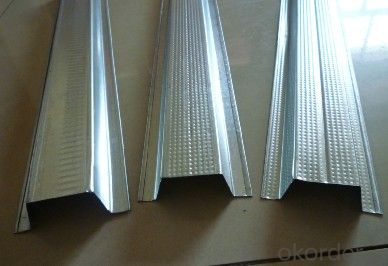

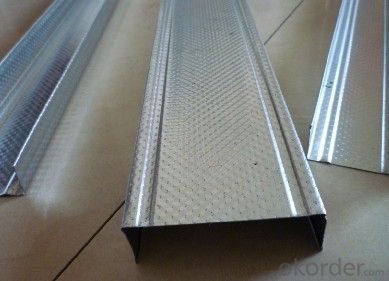

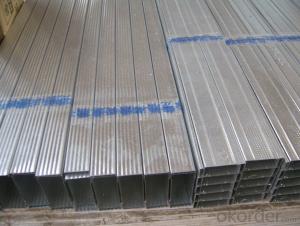

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

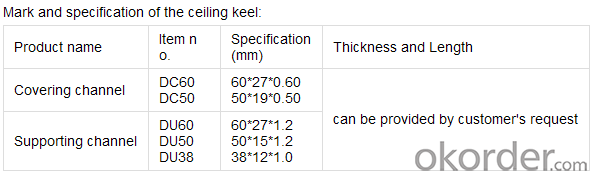

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Construction Measures of Caustic Sintered Calcium Silicate Board Ceiling 1, the roof height level: according to the level of the floor level, with the vertical bar to the ceiling design elevation, along the wall to the surrounding height of the ceiling. 2, designated keel file line: according to the design requirements of the primary and secondary keel spacing arrangement, has been on the roof of the standard elevation of the keel sub-line. 3, the installation of the main keel boom, playing a good ceiling elevation and keel sub-file position, to determine the boom under the head of the elevation, according to the main keel location and hanging spacing, the end of the bucket without screw button embedded with the floor expansion Bolt connection is fixed. 4, install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong set. Design no request, the nail spacing of 1000mm.

- Q: Toilet integrated ceiling with good or good light steel keel good

- Light steel keel is a high-quality continuous hot-dip galvanized strip as a raw material, the cold bending process from the building with metal skeleton. Fire, rust, anti-aging performance. Wood keel commonly known as the wooden side, mainly by the pine, linden wood, fir, imported drying planing and other wood processed into rectangular or square section of the wood. Easy to shape, easy to install nail sticks easy to install, especially suitable for connection with other wood products, the disadvantage is not moisture, easy to deformation, no fire,

- Q: Divided u-type light steel keel in the ceiling spacing of less than 2 meters, 2.5 meters or less, according to the large keel count spacing, or by the small keel count spacing.

- Vice keel (should be the little keel you said) and the distance between the vice keel of 30cm, gypsum board thickness of 9.5mm. If the thickness of the gypsum board is 12mm, the distance between the vice keel can be enlarged to 40cm. But in the actual construction, the vice keel spacing is 30cm, basically no one made 40cm.

- Q: Consultation: What is the keel of the living room ceiling?

- Light steel keel, it is not on the use of wood side

- Q: Light steel keel ceiling price is not expensive?

- Should be 30 --- 35 a square, plus aerial work, in 40 square

- Q: There are several specifications for light steel keel with household ceiling

- Light steel keel according to the use of hanging keel and cut keel, Product specifications series of keel main specifications are divided into Q50, Q75 and Q100. The main specifications of the ceiling keel are divided into D38, D45, D50 and D60.

- Q: Do steel keel ceiling, need to use white latex?

- If the ceiling with light steel keel, then white latex is used to stick gypsum board between the suture, not add putty but kraft paper Kazakhstan.

- Q: The construction of the lightweight steel keel gypsum board ceiling

- With a large sample can be expressed, draw the main keel, and then draw the vice keel, a few lines that on the line.

- Q: The difference between light steel keel ceiling and macadam ceiling

- The former light weight, you can easily hang a variety of modeling top, which is estimated that no advantage, weight heavier, install trouble, etc.!

- Q: Do you need to leave a gap between the ceiling and the wall? If you need to stay much in line with design requirements? Need to do those deals

- Light steel keel manuscript board ceiling and the need to stay between the wall, leaving 5MM is enough

Send your message to us

ISO 9001 Certified Ceiling Profile Drywall Metal Studs and Tracks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords