Ceiling Profile Hook Channel Ceiling System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

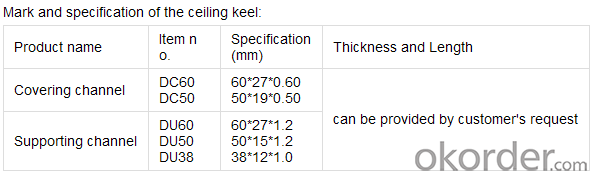

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- There is no provision for sub-dragon U line with a fixed angle on the line

- Q: Home ceiling with green steel skeleton or wooden frame

- Of course with a wooden frame

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- Light steel keel: Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on. ? Light steel keel 38 refers to the material used as keel is light steel, its cross-section and the channel is similar to the width of 38 mm series, the height of 12 mm, the thickness is not a certain value, generally depending on the force from 0.5 mm To between 1.0 mm. 38 * 12 * 0.5 38 * 12 * 0.6 38 * 12 * 0.7 38 * 12 * 0.8 38 * 12 * 1.0

- Q: Construction schedule of light steel keel ceiling

- How much area? What shape? Elaborate

- Q: Light steel keel ceiling budget how to calculate

- Hanger Light steel keel material accounting A ceiling Verification according to the construction plan on the ceiling structure and size, respectively, the calculation of each indoor ceiling of the main keel and vice keel number, and then the chamber The total number of primary and secondary keels required to add the total number of M. Taking into account the size of the construction specifications and the actual size of the difference, as well as the construction of the truncation loss and other factors, the need to add the total 3% margin, so that can be practical The total number of M required is in meters (m). The empirical formula is: M total = 1.03M Note that the total number of primary and secondary keel should be calculated separately, such as the main and vice keel of the same material, you can also be calculated.

- Q: The construction of the lightweight steel keel gypsum board ceiling

- Note that the material can be used to mark, such as hanging bars, expansion screws, the main keel, vice keel. Aluminum plate.

- Q: Whether the ceiling light steel keel has the raw material inspection standard

- The latest standard GB / T11981-2008 60 and 50 main bone thickness of 1.2mm, 38 main bone is 1.0mm, 50 bone 0.5mm, 60 bone 0.6mm

- Q: Light steel keel ceilings are the main keel specifications is how much

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

- Q: Wood keel and light steel keel were used for where?

- Light steel keel main use in a large area of the ceiling, the general home decoration in addition to kitchen and steel is used outside the light keel are used wood keel. Be sure to pay attention to full brush fire retardant coating.

- Q: Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- The kind of keel is determined by the material of the ceiling. Light steel keel for, gypsum board, integrated ceiling, relief gypsum board mineral wool board (both bones for the paint). Kitchen and other basic not suitable, integrated ceiling can be. If only the ordinary buckle top, it must be wood keel, or can not be fixed pinch. On the issue of cost-effective, light steel keel and wood keel basically no comparable, the same area of the former price of the latter twice as much as the latter, but iron is better than wood. Home improvement basically no light steel keel, because the kitchen is not suitable, in the living room after the ceiling height than the keel to 10 cm lower.

Send your message to us

Ceiling Profile Hook Channel Ceiling System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords