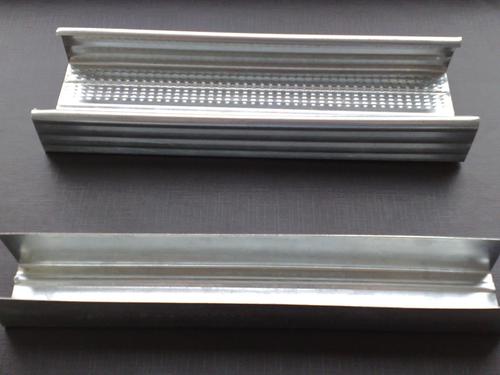

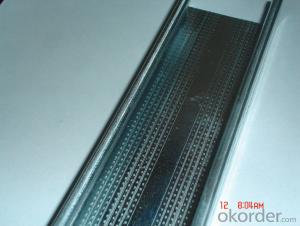

Ceiling Profile Steel Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Galvanized Steel Sheet

Application: Drywall ceiling and partition system

Size: different items / series for different markets

Thickness: 0.40~1mm

Length: Normal 3m/piece, can be customized

Zinc coated: Normal 40~50g/m2, can be customized

Function: Fireproof, Waterproof, Rustproof

Packaging Detail: in bundle, then into containers

Advantages and features:

1. Light, good strength, cauterization resistance and water resistance;

2. Matching different kinds of wall boards, such as gypsum board, fiber cement board, magnesium oxied board;

3. Moisture -proof, shock-resistance, high-effecient, environmentally-friendly and so on;

4. Easy and fast for installation, time-saving;

5. Prompt delivery, high quality, competitive price and complete sets of style;

6. Can supply products based on specific requirements;

- Q: Please give valid certificate, thank you! The

- Light steel keel and ceiling keel to have a test report of the general once a year.

- Q: Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- General ceiling, then we must play a few holes in the top, with the screw to the keel fixed to live, are generally 30 ..... 40 public lattice. Playing off on the top of the root keel, the following root keel There 's what' s the keel in the middle. , For a long time did not do that line, looking at it, that the distance is the best 30 cm, not more than 40 cm

- Q: Light steel keel ceiling hanging bar spacing how much?

- 30 cm to 40 cm between

- Q: Toilet integrated ceiling with good or good light steel keel good

- Light steel keel is a high-quality continuous hot-dip galvanized strip as a raw material, the cold bending process from the building with metal skeleton. Fire, rust, anti-aging performance. Wood keel commonly known as the wooden side, mainly by the pine, linden wood, fir, imported drying planing and other wood processed into rectangular or square section of the wood. Easy to shape, easy to install nail sticks easy to install, especially suitable for connection with other wood products, the disadvantage is not moisture, easy to deformation, no fire,

- Q: Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- With light steel keel with three or four to mention the mention of the shape of it! Absolutely solid!

- Q: What is the light steel keel?

- Light steel (paint) keel, is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction, etc., by the user and the design unit widely used. Light steel keel and paint keel is the difference between the general light steel keel is not painted surface treatment, making coating (galvanized), and paint keel surface made paint, generally divided into black and white, a few according to the design requirements baked into other colors, Mainly because most of the paint keel used in the Ming keel, paint is to ensure that the exposed part of the rust does not affect the appearance.

- Q: Tectonic levels and practices of light steel keel

- First find the ceiling of the horizontal line, and then installed in the roof on the big expansion screws. Under the boom, the distance from the boom do not exceed 80mm installation hook, and then on the 38 keel hanging with the installation of the vice keel we generally do 40mm grid, gypsum board specifications are 120mm / 3000mm. Gypsum board installation to stay, 5mm gap. Then there is adhesive powder leveling. And then stick to the bandage, in the putty putty, brush paint.

- Q: Light steel keel specifications

- Simply talk to you about the connection between the keels: the boom with a bolt bolts fixed on the floor, with T-type keel hanging pieces connected T-shaped main keel, T-keel for long, in its interface with T-keel connections fixed, between the keel and the main keel is connected between the plug, you can not accessories. If the ceiling has an additional load or a large area of the ceiling, you need U-bearing keel, that is, after the installation of the boom, first with U-shaped keel (main keel) hanging pieces will U-shaped main keel and boom connection, T-type keel pendant will T-shaped longitudinal keel and U-shaped main keel connection

- Q: Seeking: light steel keel mineral wool board ceiling, the general how much money a square? (The installation is complete)

- Different regions, different brands are not the same price, we generally installed here to complete 1 square meters 50 to 60 yuan

- Q: The construction of the lightweight steel keel gypsum board ceiling

- Note that the material can be used to mark, such as hanging bars, expansion screws, the main keel, vice keel. Aluminum plate.

Send your message to us

Ceiling Profile Steel Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords