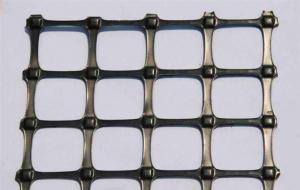

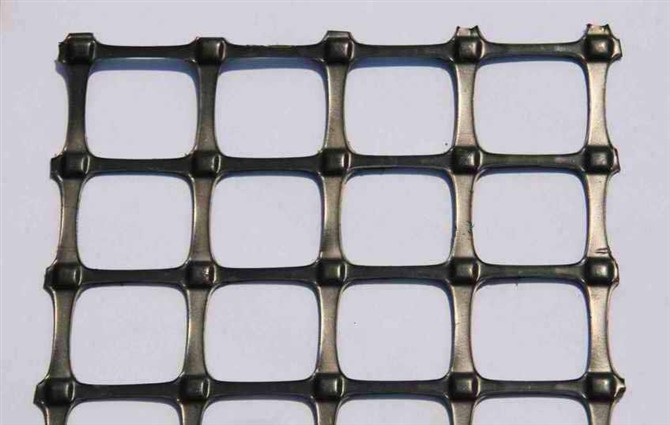

Titan Geogrids PP Biaxial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial Plastic Geogridfor Coal Mine road Railway highway

It is made from polymer and nanometer carbon black by extruded method .

Specification of Biaxial Plastic Geogrid for Coal Mine road Railway highway

L. Tensile strength (MD and TD)not less than 30kN/m

2. ROll width 2-4m, length as request

Property of BiaxialPlastic Geogrid for Coal Mine road Railway highway:

L. Not easy to produce static after friction. In the coal mine, surface staticresistance average is

Below lx109(LC

2. Good flame retardant performance, melt not burning under flam environment,even burning it

Will extinguish in lOs

3. Strong anti-corrosion property

4. High bearing capacity, low elongation

Application of Biaxial Plastic Geogrid for Coal Mineroad Railway highway:

Coal mine channels, more than 2 layers needed if for false roof use.

Production standard:

Q/LHX 02-2009

- Q: What are the six main functions of Geosynthetics

- The special geotechnical synthetic material also includes the soil cushion, the earthwork net, the geogrid, the geocell, the geomembrane bag and the geotechnical foam.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in expansive soils?

- Geogrids improve the performance of mechanically stabilized slopes in expansive soils by providing reinforcement and increasing the overall stability of the slope. They help to distribute and reduce the tensile forces within the soil, preventing cracks and failures caused by soil expansion and contraction. Geogrids also enhance the load-bearing capacity of the soil, allowing for better resistance against lateral movement and minimizing potential slope instability.

- Q: Can geogrids be used in green roof applications?

- Yes, geogrids can be used in green roof applications. Geogrids provide stability and reinforcement to the green roof system, helping to prevent soil erosion and promote the growth of vegetation. They can also help distribute the weight of the green roof evenly, reducing the stress on the building structure.

- Q: How to effectively control the quality of Geogrid in the process of construction

- 2 the surface of the bearing surface of the geosynthetics shall be leveled and compacted, and the hard and protruding surface shall be removed.

- Q: What kind of material is the geogrid in the quota

- The utility model relates to a three-dimensional grid screen with a certain height, which is used as a civil engineering, and is called a geogrid geogrid.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of geogrid used can significantly impact the overall cost. Higher quality geogrids may be more expensive but can provide better reinforcement, leading to longer-lasting and more cost-effective structures. Additionally, the design and engineering of the structure play a crucial role. Properly designed structures that consider factors such as soil conditions, loading requirements, and anticipated lifespan can ensure optimal performance and cost-effectiveness. The construction process and techniques employed also influence the cost-effectiveness. Efficient construction methods, skilled labor, and effective project management can minimize costs and maximize the durability and longevity of the geogrid-reinforced structure. Lastly, the maintenance and monitoring of the structure are essential. Regular inspections and timely repairs, if needed, can prevent costly damages and extend the lifespan of the structure, ultimately enhancing its cost-effectiveness.

- Q: Are geogrids suitable for use in mechanically stabilized bridge abutments?

- Yes, geogrids are suitable for use in mechanically stabilized bridge abutments. Geogrids provide reinforcement and stability to the soil, allowing for increased load-bearing capacity and reduced settlement. They are commonly used in bridge abutments to improve the overall performance and longevity of the structure.

- Q: Can geogrids be used in retaining walls for residential applications?

- Yes, geogrids can be used in retaining walls for residential applications. Geogrids are commonly used to reinforce and stabilize retaining walls, providing additional strength and stability to the structure. They help prevent soil erosion, improve drainage, and increase the overall durability of the retaining wall.

- Q: What is the effect of aging on geogrid properties?

- The effect of aging on geogrid properties is that it can lead to a decrease in strength and stiffness, as well as an increase in brittleness and susceptibility to environmental factors such as UV radiation and temperature fluctuations.

- Q: What are the typical applications of geogrids?

- Geogrids are commonly used in various civil engineering applications. They are primarily used for soil stabilization, reinforcement, and erosion control in projects such as retaining walls, slopes, embankments, roadways, and pavements. Geogrids help improve the overall strength and stability of these structures by distributing loads, reducing lateral movement of soil, and preventing soil erosion.

Send your message to us

Titan Geogrids PP Biaxial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords