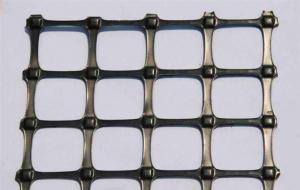

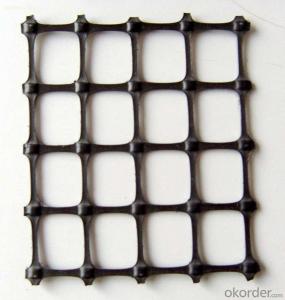

Neoloy Geocells PP Unixial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Uniaxial Plastic Geogrid for road railway highwayprojects Made from polymerand nano scale carbon black by extrusion technology

Specification ofUniaxial Plastic Geogrid for road railway highway projects:

I. TGDG35, TGDG50, TGDG80, TGDG120, TGDG160, TGDG260, TGDG300 etc

2. Lm t0 3m in roll width

Property of UniaxialPlastic Geogrid for road railway highway projects:

I. Roadbed reinforcement, improve stability and bearing capacity

2. Prevent roadbed from deformation and crack due to roadbed material wash off

3. Retaining wall bearing capacity improvement

Application of UniaxialPlastic Geogrid for road railway highway projects:

I. Roadbed reinforcement in highway

2. Municipal road, railway, airport runway

3. Dam reinforcement

4. Garden fence and river bank

5. Retaining wall reinforcement in highway

Production standard ofUniaxial Plastic Geogrid for road railway highway projects:

G B/T17689-2008

JT/T 480-2002

- Q: What are the advantages of using geogrids in soil nailing applications?

- Geogrids offer several advantages in soil nailing applications. Firstly, they provide additional reinforcement to the soil, improving its stability and preventing slope failures. Secondly, geogrids help distribute loads more evenly, reducing the stress on the soil and increasing its bearing capacity. Additionally, geogrids can be easily installed, saving time and labor costs. They are also durable and resistant to environmental factors such as corrosion and degradation. Overall, using geogrids in soil nailing applications enhances the effectiveness and longevity of the stabilization process.

- Q: Geogrid and geotextile, the role is the same?

- In short, the role of geogrid is to stabilize the roadbed, extend the service life of the road

- Q: Can geogrids be used in reinforcement of reinforced soil slopes?

- Yes, geogrids can be used in the reinforcement of reinforced soil slopes. Geogrids are often used to enhance the stability and strength of soil structures by providing tensile reinforcement.

- Q: What does the geotextile 200# mean?

- Is 200g/ square meters of geotextiles? The geotextile is generally divided according to the specifications of the weight per unit area. Geotextiles manufacturers Zhang Mingchao answer for you, and I hope to help you.

- Q: Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used to reinforce soil and provide stability in various applications, including agriculture. They can effectively improve soil strength, prevent erosion, and support the growth of crops, making them suitable for soil stabilization in the agricultural sector.

- Q: Tgsg5050 what is the difference between Geogrid and gsz5050?

- 30-30 "means: per meter of longitudinal and transverse tensile force is greater than the yield of 30KN/m. can be said to be the same.

- Q: Can geogrids be used in seismic zones?

- Yes, geogrids can be used in seismic zones. Geogrids are commonly used in geotechnical engineering to reinforce soils and provide stability to structures. They can also help mitigate the effects of earthquakes by distributing the seismic forces and reducing soil liquefaction. However, specific design considerations and geogrid properties should be taken into account to ensure their effectiveness in seismic zones.

- Q: Self adhesive fiberglass geogrid price 1m2 how much money

- The higher the tension, the higher the price

- Q: Who knows the laying method of geogrid?

- Roller compaction of C. rubber tyred roller.D. 50? 0,.3mm of the fixed iron sheet, the requirements of flat angle, the edge of the appropriate chamfer treatment, 2 inch steel nails (high quality cement nails)When the e nail fixation method is used for laying fiberglass geogrid, one end is fixed on the lower layer of the structure of the asphalt layer which has been sprayed with a fixed iron sheet and a nail. When the grating is tensioned longitudinally, the glass fiber is in a straight and tight state.

- Q: Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids are specifically designed to enhance the stability and strength of weak soils, such as soft subgrades. By distributing the load and improving soil confinement, geogrids can effectively reduce settlement and improve the overall performance of the subgrade.

Send your message to us

Neoloy Geocells PP Unixial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords