Anodized Aluminum Molding Strips Sheet and Coil for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

2. Application of Aluminum

(1).Alumina

(2). Facades, roofing, canopies, tunnels,column Sulfates

(3).Niche compounds..

3. Feature of Aluminum

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

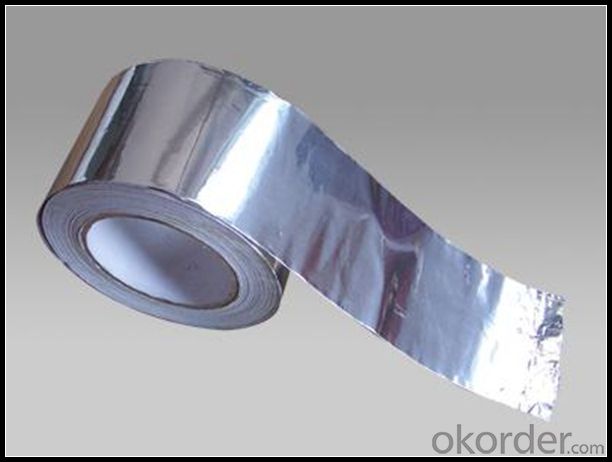

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Aluminum foil tape insulation principle, why insulation?

- The air conditioner foil is a special material for the heat exchanger fin of an air conditioner, and an early air conditioner foil is a plain foil. In order to improve the surface properties of the plain foil, an anticorrosive inorganic coating and a hydrophilic organic coating are applied before forming to form hydrophilic foil. At present, hydrophilic foil accounts for 50% of the total amount of air conditioning foil, and its use ratio will be further improved. There is also a hydrophobic foil, so that the fin surface has hydrophobic function, prevent condensation water adhesion. Because of hydrophobic foil, the technology of improving surface defrosting needs to be studied further.

- Q: What types of aluminum are known for their high strength and resistance to wear and tear?

- <p>Yes, certain types of aluminum alloys are known for their exceptional strength and resistance to wear and tear. 7075 aluminum, for instance, is one of the strongest aluminum alloys, often used in aerospace and automotive applications due to its high strength-to-weight ratio. Another example is 6061 aluminum, which is commonly used in structural applications because of its good mechanical properties and resistance to corrosion. These alloys achieve their strength through the addition of elements like copper, magnesium, and zinc, which enhance their properties for specific industrial uses.</p>

- Q: What types of aluminum are more cost-effective for specific applications?

- <p>Yes, there are different types of aluminum alloys that offer varying degrees of cost-effectiveness depending on the application. For instance, 1100 series aluminum, which is 99% pure, is the most cost-effective due to its low alloying content but has limited strength. On the other hand, 6000 series alloys, like 6061, are stronger and more durable, making them ideal for structural applications but slightly more expensive. The choice depends on factors like strength, corrosion resistance, and weight requirements, which can influence the cost-effectiveness of an aluminum alloy for a specific use.</p>

- Q: This question asks about potential dangers associated with using aluminum strips in a residential setting.

- <p>Using aluminum strips in a home can pose several safety issues. Firstly, aluminum is a good conductor of electricity, so if it comes into contact with live electrical wires, it can cause short circuits or even electrocution. Secondly, aluminum strips can be sharp and may cause cuts or injuries if handled improperly. Additionally, aluminum dust can be harmful if inhaled, potentially causing respiratory issues. Lastly, in the event of a fire, aluminum can melt and release toxic fumes, posing a significant health risk. It's crucial to handle aluminum strips with care and ensure they are used in a safe manner, away from electrical sources and in a well-ventilated area.</p>

- Q: What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- The aluminum plate and the aluminum band are better understood. One is the plate and the other is the coil.

- Q: Is it possible to utilize aluminum strips instead of conventional siding materials in areas with high temperatures?

- <p>Yes, aluminum strips can be used to replace traditional siding materials in hot climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand high temperatures. It reflects heat, reducing the amount of heat absorbed by the building, making it a suitable choice for hot climates. Additionally, aluminum siding is low maintenance and can be easily painted or finished to match the desired aesthetic. However, it's important to consider factors such as insulation properties and potential for condensation, as aluminum may not insulate as well as some other materials.</p>

- Q: What specific tools are required for the installation of aluminum strips on a roof or wall?

- <p>To install aluminum strips on a roof or wall, you generally need a few special tools. These include a measuring tape for precise measurements, a level to ensure the strips are straight, a drill for making holes, and screws or nails for securing the strips. A utility knife may be required for cutting the strips to size, and a pry bar can help with positioning. Safety equipment like gloves and goggles is also essential to protect against sharp edges and debris.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof or wall.

- <p>To install aluminum strips on a roof or wall, follow these steps: 1. Measure and mark the area where the strips will be installed. 2. Clean the surface thoroughly to ensure proper adhesion. 3. Cut the aluminum strips to the required length using a hacksaw or tin snips. 4. Apply a bead of construction adhesive along the top edge of the strip. 5. Press the strip firmly into place, starting from one end and working your way along the surface. 6. Use a level to ensure the strip is straight and secure it with nails or screws at regular intervals. 7. Fill any gaps between the strips and the surface with caulk to create a watertight seal. 8. Finish with a coat of paint or sealant to match the surrounding area and protect the aluminum from weathering. Always follow the manufacturer's instructions for the specific adhesive and sealant products you are using.</p>

- Q: Can the 6 square aluminum wires carry 3 pieces of air?

- 6 square aluminum core copper wire line is equivalent to 4 square, line laying the safety current of about 25A, can withstand the electric power of 5500 watts or less, while the air conditioning refrigeration power three 2500 watt in general, heating and electric power auxiliary is 5000 Watt or less, so the use of aluminum the core 6 square is no problem.

Send your message to us

Anodized Aluminum Molding Strips Sheet and Coil for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords