The production of hydrogen 15CrMo steel in Wuyang steel works

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydrogen 15CrMo (H) containing WYJ testing, heat treatment, is more than or equal to -10 DEG C im

Hydrogen 15CrMoR, 15CrMoR (H) technical conditions of steel plate production

1 the use of range from Wuyang steel quality management department

The technical conditions applicable to the medium temperature pressure vesselpressure components with less than 150mm thickness of the steel plate.

2 normative references GB713-2008

In 3 dimensions, shape, weight and permissible deviations

3.1 steel plate size, shape and tolerances shall comply with the provisions of GB/T709. 3.2 thickness deviation according to B class or the C GB/T709 class in the contract execution, Naka A.

3.3 plate theoretical weight delivery, theoretical weight the maximum thickness ofsteel plate thickness is permitted and the minimum thickness of the arithmetic mean value. The density of steel 7.85g/ cm 3

The chemical composition of steel requirements, shall be in accordance with the provisions of table 1. Table 1 chemical composition of Wt% components

C Si Mn P Analysis of the S Max Cr Mo melting

0.12~ ~ ~ ~ ~ ~ 0.18 0.15 0.40 0.40 0.70 0.010 0.010

Analysis of 0.8 ~ 1.2 0.45 ~ 0.60 of the finished product

0.10~ ~ 0.20 0.13 ~ ~ 0.43 0.37 ~ ~ 0.73 0.012 0.010 0.75 ~ ~ 1.25 0.43 ~ ~ 0.62

Analysis of Ni Cu Sb* Sn* component of As* Max [H]* melting

Analysis of 0.20 and 0.20 is less than or equal to 0.003 is less than or equal to 0.015 and 0.016 2ppm products

0.20 0.20 0.003 0.015 0.016

Less than or equal to 2ppm

Note: (1) melting analysis should be per furnace (tank), sampling, analysis of products (including the X coefficient) according to Zhang sample delivery. (2) with "*" the element record analysis results. [H] under the premise of ensuring meltinganalysis, but not for the product analysis. Methods: 4.2 smelting by electric furnace+ refining outside the furnace, and through smelting process vacuum degassing.The plates shall be fine grain steel. 4.3 delivery state: steel plate to normalizing + tempering (allows accelerated cooling) delivery. 4.4 mechanical properties, shallcomply with the provisions of table 2. Table 2 project numerical unit room temperature tensile Rm

Thickness is less than or equal to 100mm 450~~590 MPa

>100~150mm 440~~580 room temperature tensile Rp0.2 less than 100mm thickness greater than 295 MPa

>100~150mm

255

Methods: using electric furnace smelting furnace refining, and through + vacuum degassing of the smelting process. The plates shall be fine grain steel. 4.3 delivery state: steel plate to normalizing + tempering (allows accelerated cooling) delivery.

- Q: What are the common surface treatments for steel sheets?

- The common surface treatments for steel sheets include galvanizing, powder coating, painting, and plating.

- Q: Can the steel sheets be easily cleaned?

- Certainly, steel sheets can be effortlessly cleaned. Renowned for their durability and low-maintenance nature, steel sheets can be swiftly wiped down with a damp cloth or sponge accompanied by mild soap or detergent. In the case of stubborn stains or grime, a non-abrasive cleaner is recommended. Moreover, steel sheets exhibit exceptional resistance to rust and corrosion, rendering them well-suited for diverse settings and ensuring hassle-free maintenance in the long term.

- Q: What is the hardness of steel sheets?

- The hardness of steel sheets can vary depending on the specific type and grade of steel, but generally, steel sheets have a high level of hardness ranging from 30 to 60 on the Rockwell C scale.

- Q: Are steel sheets resistant to rot or decay?

- Yes, steel sheets are highly resistant to rot or decay.

- Q: Are steel sheets resistant to warping under heat?

- Yes, steel sheets are generally resistant to warping under heat due to their high melting point and excellent thermal conductivity.

- Q: What are the different surface treatments for color-coated steel sheets?

- Some common surface treatments for color-coated steel sheets include chromating, galvanizing, and powder coating. Chromating involves applying a chemical solution to the surface to enhance corrosion resistance and adhesion of the color coating. Galvanizing is a process where a layer of zinc is applied to the steel sheet to provide both corrosion protection and a durable base for the color coating. Powder coating involves electrostatically applying dry powder to the surface and then curing it under heat to create a tough, decorative finish.

- Q: What is the thickness of the water resisting steel plate of the electrical outlet?

- According to the standard atlas "waterproof sleeve 02S404", the thickness of the water stopping ring steel plate should be 10mm~14mm.

- Q: Can steel sheets be used for railway applications?

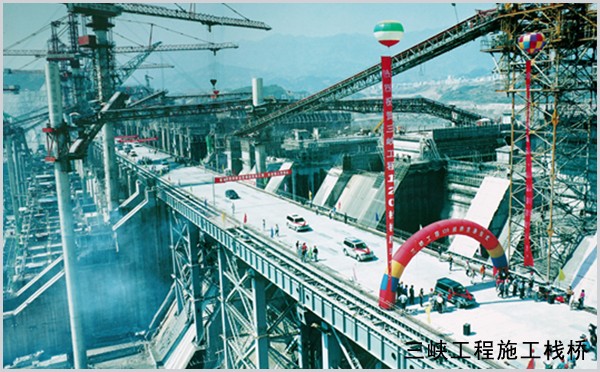

- Yes, steel sheets can be used for railway applications. Steel sheets are commonly used in the construction of railway tracks, bridges, and other infrastructure due to their high strength, durability, and resistance to wear and tear. They provide a stable and reliable foundation for railway systems, ensuring safe and efficient transportation.

- Q: Are the steel sheets suitable for automotive applications?

- Steel sheets are an excellent choice for automotive applications due to their exceptional strength, durability, and versatility. The automotive industry widely employs steel because of these qualities. It offers outstanding crash resistance, making it perfect for ensuring passenger safety in vehicle structures. Furthermore, steel sheets can easily be molded into intricate shapes, enabling the production of various automotive components like body panels, chassis, and frames. Steel also possesses excellent corrosion resistance, which is crucial for enduring harsh environmental conditions. In addition, it is cost-effective and readily accessible, making it a preferred option for automakers. All in all, steel sheets prove to be a dependable and fitting material for automotive applications.

- Q: Can steel sheets be used for architectural purposes?

- Yes, steel sheets can be used for architectural purposes. Steel sheets are versatile and widely used in architecture due to their strength, durability, and flexibility. They can be used for various architectural elements such as roofs, walls, cladding, and structural components. Additionally, steel sheets offer a wide range of design possibilities and can be easily customized to meet specific architectural requirements.

Send your message to us

The production of hydrogen 15CrMo steel in Wuyang steel works

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords