Cold Rolled Steel Coils 304,Cold Rolled Steel Plates 316 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

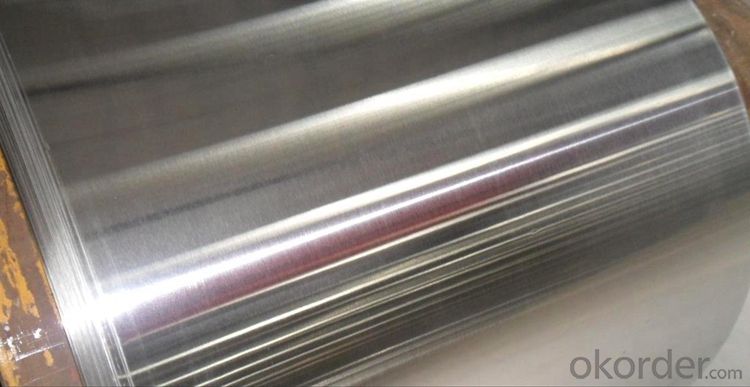

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for decorative purposes?

- Certainly, decorative purposes can be served by stainless steel sheets. Renowned for its sleek and contemporary look, stainless steel is a widely preferred option for diverse decorative uses. Its applications span across interior design, architecture, and even art installations. Stainless steel sheets can be personalized to fashion distinctive patterns, textures, and finishes, rendering them ideal for crafting captivating and visually enticing decorative elements. Moreover, stainless steel boasts exceptional durability, corrosion resistance, and simple maintenance, making it a pragmatic choice for both indoor and outdoor decorative applications.

- Q: Are stainless steel sheets resistant to stress corrosion cracking?

- Stainless steel sheets generally display resistance to stress corrosion cracking. This is because of their elevated levels of chromium and nickel, which grant exceptional anti-corrosive properties. Stress corrosion cracking refers to a form of corrosion that arises when subjected to tensile stress in a corrosive setting. Stainless steel sheets are alloyed with materials that generate a passive protective layer on the surface, making them highly resistant to corrosion and preventing stress corrosion cracking. However, it is worth noting that the resistance to stress corrosion cracking may vary depending on the precise stainless steel grade and the environmental conditions it encounters. Consequently, it is advisable to consult the manufacturer or consult corrosion resistance charts to ensure the appropriate stainless steel grade is chosen for specific applications.

- Q: Can stainless steel sheets be used for medical sterilization equipment?

- Yes, stainless steel sheets can indeed be used for medical sterilization equipment. Stainless steel is a popular material choice in the medical industry due to its excellent resistance to corrosion, high heat resistance, and durability. These features make stainless steel sheets ideal for various medical applications, including the construction of sterilization equipment. Stainless steel sheets can withstand high temperatures and repeated sterilization cycles without warping or degrading, making them suitable for autoclaves and other sterilization devices. Additionally, stainless steel is easy to clean and maintain, which is crucial for preventing the growth of bacteria or other harmful microorganisms. Thus, stainless steel sheets are commonly used in medical settings where sterilization equipment is required.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can follow these simple steps: 1. Start by gathering the necessary cleaning supplies. You will need a microfiber cloth, mild dish soap, warm water, and a stainless steel cleaner or vinegar. 2. Begin by dampening the microfiber cloth with warm water. Make sure the cloth is not soaking wet, just slightly damp. 3. Gently wipe the stainless steel surface in the direction of the grain. It is important to always follow the grain to avoid causing scratches or streaks. 4. If the fingerprints persist, you can add a small amount of mild dish soap to the damp cloth and continue wiping the surface. Be sure to rinse the cloth thoroughly after applying the soap. 5. If the fingerprints are still visible, you can use a stainless steel cleaner specifically designed for brushed stainless steel surfaces. Apply a small amount of the cleaner onto the microfiber cloth and wipe the surface in the direction of the grain. Remember to follow the manufacturer's instructions for the specific cleaner you are using. 6. Alternatively, you can use white vinegar as a natural cleaning solution. Dampen a cloth with vinegar and gently wipe the surface in the direction of the grain. Vinegar can help remove fingerprints and restore shine. 7. Once you have removed the fingerprints, use a dry microfiber cloth to buff the surface gently. This will help remove any remaining streaks and give the stainless steel a polished finish. Remember to always test any cleaning solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, avoid using abrasive materials or cleaners that contain chlorine or bleach, as they can damage the brushed finish of the stainless steel.

- Q: Are stainless steel sheets suitable for medical equipment?

- Indeed, medical equipment can be fabricated using stainless steel sheets. The utilization of stainless steel in medical equipment is widely favored due to its remarkable resistance to corrosion and its ability to endure. It boasts effortless cleaning and sterilization, rendering it fitting for employment in healthcare facilities where cleanliness and hygiene are paramount. Furthermore, the high strength-to-weight ratio of stainless steel permits the creation of lightweight yet robust medical equipment. Moreover, its magnetic permeability is low, rendering it an ideal option for situations necessitating minimal electromagnetic interference. All in all, stainless steel sheets are a dependable and pragmatic selection for the production of medical equipment.

- Q: How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q: What are the different types of edge finishes for stainless steel sheets?

- There are several types of edge finishes for stainless steel sheets, including square edge, round edge, beveled edge, and rolled edge. Each of these finishes provides a different aesthetic and functional appeal, catering to different design preferences and project requirements.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, there are several preventive measures that can be taken: 1. It is crucial to handle stainless steel sheets properly, avoiding any scratching or rubbing of the surface that could lead to fretting corrosion. Gloves should be worn and contact with other metals or rough surfaces should be avoided. 2. Regular cleaning of the stainless steel sheets using mild detergents or specialized stainless steel cleaners is recommended. This helps to remove contaminants that can initiate corrosion and prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion, especially in applications with repeated movement or vibration. 4. Whenever possible, it is advised to isolate stainless steel sheets from direct contact with other metals. This can be achieved by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular inspection of the stainless steel sheets is important to detect any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. It is recommended to consult with a professional to determine the most suitable coating for the specific application. 7. Proper storage of stainless steel sheets is essential. When not in use, they should be stored in a clean, dry environment to minimize exposure to moisture or corrosive substances. The storage area should be well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, the risk of fretting corrosion on stainless steel sheets can be significantly reduced, ultimately prolonging their lifespan.

- Q: Are stainless steel sheets suitable for medical applications?

- Yes, stainless steel sheets are suitable for medical applications. Stainless steel is a popular choice in the medical field due to its excellent corrosion resistance, durability, and ease of sterilization. It is commonly used in medical equipment, surgical instruments, implants, and even architectural applications within healthcare facilities. Stainless steel is highly resistant to staining, bacterial growth, and contamination, making it a hygienic and safe material for medical use. Additionally, its strength and low maintenance requirements make it suitable for long-term use in demanding medical environments. Overall, stainless steel sheets meet the stringent requirements of medical applications and are a reliable choice for healthcare professionals.

- Q: Are stainless steel plates 3.4mm or 3.5mm thick?

- The thickness of less than 1mm of any size 0.05mm times, thickness more than 1mm of any size 0.1mm times;According to standard GB/T 709-2006 hot rolled steel sheet size tolerances, the stainless steel sheet thickness is 3~400mm,

Send your message to us

Cold Rolled Steel Coils 304,Cold Rolled Steel Plates 316 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords