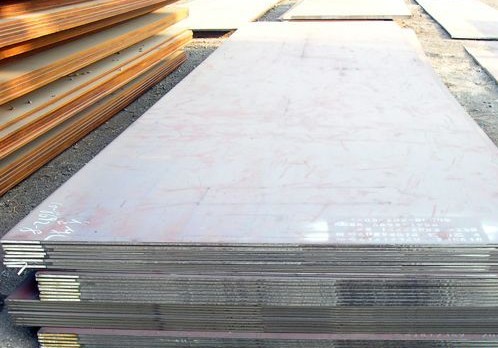

A515Gr70 steel production in Wugang

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SA515Gr70belonginlowcarbonsteelpressure vessels,performASMEstandards,Wugang2006R & Dproduction,is widely used inpetroleum, chemical, power plants,boilers and otherindustries for the productionreactors,heat exchangers,separators,ballcans,gas tanks, nuclearreactor pressure vessel,boiler drum,hydropowerhigh pressurepipes,water wheelsvoluteother equipment and components.

1.SA515Gr60, SA515Gr70, SA516Gr60, SA516Gr70, SA516Gr60N, SA516Gr70Nthickness≤1.5in, (40mm)steelis usuallysupplied inrolled condition, steelcan also benormalized oreliminate stress,or normalizedstress relievingorders.

2thickness> 1.5in. (40mm)steelshould benormalized.

4, ifapprovedby the demand side,allows the use oflarger than thecooling ratein the airto improve thetoughness,butas long as thesubsequentsteel1100-1300°F (595-705 ℃)within a range oftempering.

Q245R、Q345R、Q370R、16MnDR、15CrMoR、09MnNiDR、SA285GrC、19Mn6、P355GH、15Mo3、SPV355、15MnVR、14Cr1MoR、SA515Gr60/70、SA516Gr60/70、A48CPR

SA515Gr60 / 70is widely used inpetroleum, chemical,power plants,boilers and otherindustries for the productionreactors,heat exchangers,separators, tank, notank, nuclearreactor pressure vessel,boiler drum,hydropowerhigh pressurepipes,waterscrollwheeland other equipment andcomponents.

Grade thickness width length remarks

SA515Gr60 8 2300 10000 FourcutGuaranteed

SA515Gr60 185 3815 10322

A515Gr60 25 2400 12000 FourcutGuaranteed

SA515Gr60 30 2500 11400

SA515Gr60 36 2300 10000 FourcutGuaranteed

SA515Gr60 40 2520 8400

SA515Gr60 50 2300 10000 FourcutGuaranteed

SA515Gr60 60 2000 10000

SA515Gr60 80 2560 10800

SA515Gr60 100 2700 8900 FourcutGuaranteed

SA515Gr60 120 2550 10500

SA515Gr60 200 2550 3330

- Q: What is the difference between a hot rolled and hot dipped galvanized steel sheet?

- A hot rolled steel sheet is produced by rolling the steel at high temperatures, typically above 1,000 degrees Fahrenheit. This process allows the steel to be shaped and formed easily, resulting in a sheet with a rougher and less precise surface finish. Hot rolled steel sheets are commonly used in applications where strength and durability are key factors, such as in construction and structural projects. On the other hand, a hot dipped galvanized steel sheet goes through an additional process after being hot rolled. The steel sheet is immersed in a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating provides excellent corrosion resistance and helps to prevent rusting, making hot dipped galvanized steel sheets ideal for outdoor and exposed applications. The main difference between the two types of steel sheets lies in their surface finish and protective properties. While hot rolled steel sheets have a rougher surface, hot dipped galvanized steel sheets have a smoother and more uniform appearance due to the zinc coating. Additionally, the galvanization process provides enhanced corrosion protection to the steel, extending its lifespan and making it suitable for harsh environments. In summary, hot rolled steel sheets are versatile and commonly used in various applications, while hot dipped galvanized steel sheets offer added protection against corrosion and are often preferred for outdoor or exposed applications.

- Q: What are the insulation properties of steel sheets?

- Compared to other commonly used insulation materials like fiberglass or foam, steel sheets have relatively poor insulation properties. This is because steel is an excellent conductor of heat and electricity, possessing high thermal conductivity. Consequently, steel sheets are ineffective in preventing heat transfer and are not typically used as standalone insulation materials. Nonetheless, steel sheets can still offer some insulation benefits when utilized alongside other insulating materials. For example, they can serve as a protective layer or cladding, enhancing the durability and fire resistance of insulation systems. Additionally, they can function as a radiant barrier, redirecting heat away from buildings and reducing heat gain in warm climates. To summarize, although steel sheets themselves do not possess exceptional insulation properties, they can contribute to improving overall insulation performance when combined with other insulating materials or applied in specific scenarios such as radiant barriers.

- Q: How can the white steel plate be bright and cleaned?

- The use of detergent plus iron cloth rub, salt, vinegar 50 ml into the bowl, then add a little detergent thoroughly, with a cloth dipped in salt and vinegar detergent water rubbed white plate, not only can remove stains, can maintain the original brightness.

- Q: Can steel sheets be used in corrosive environments?

- Yes, steel sheets can be used in corrosive environments, but the type of steel used and the proper protective measures need to be taken into consideration. Stainless steel, for example, is highly resistant to corrosion and can withstand harsh environments. It contains chromium, which forms a protective oxide layer on the surface, preventing corrosion. Galvanized steel is another option, where a layer of zinc is applied to the steel surface, providing a protective barrier against corrosion. Additionally, various coatings such as epoxy, polyurethane, or paint can be applied to steel sheets to enhance their resistance to corrosive elements. It is important to select the appropriate steel grade and protective coatings based on the specific corrosive environment to ensure long-lasting performance. Regular inspections and maintenance are also necessary to identify and address any potential signs of corrosion.

- Q: What is the typical weight of steel sheets?

- The typical weight of steel sheets can vary depending on the thickness and dimensions of the sheet. However, a commonly used gauge for steel sheets is 16 gauge, which typically weighs around 40 to 50 pounds per square foot.

- Q: Are steel sheets resistant to warping or bending under load?

- Yes, steel sheets are generally resistant to warping or bending under load due to their high strength and stiffness.

- Q: How do steel sheets compare to other materials like aluminum or copper?

- Steel sheets have several advantages over other materials like aluminum or copper. First, steel is generally stronger and more durable, making it suitable for a wide range of applications. Additionally, steel has a higher melting point than aluminum, making it better suited for high-temperature environments. Steel sheets are also relatively more affordable and readily available compared to copper, making them a cost-effective choice for many industries. However, it's important to consider specific requirements and characteristics of each material before making a final comparison.

- Q: Are steel sheets resistant to warping and twisting?

- Yes, steel sheets are highly resistant to warping and twisting due to their inherent strength and rigidity properties.

- Q: Can steel sheets be used for automotive exhaust systems?

- Yes, steel sheets can be used for automotive exhaust systems. Steel is a commonly used material for exhaust systems due to its durability, heat resistance, and cost-effectiveness. Steel sheets are often formed and welded to create the necessary components of an exhaust system, such as pipes, mufflers, and catalytic converters.

- Q: Are steel sheets prone to warping or bending?

- Yes, steel sheets are prone to warping or bending under certain conditions, such as exposure to high heat or excessive force. However, the extent of warping or bending also depends on the thickness and quality of the steel sheet.

Send your message to us

A515Gr70 steel production in Wugang

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords