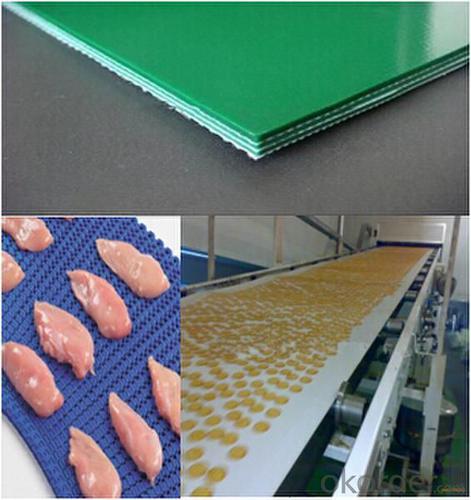

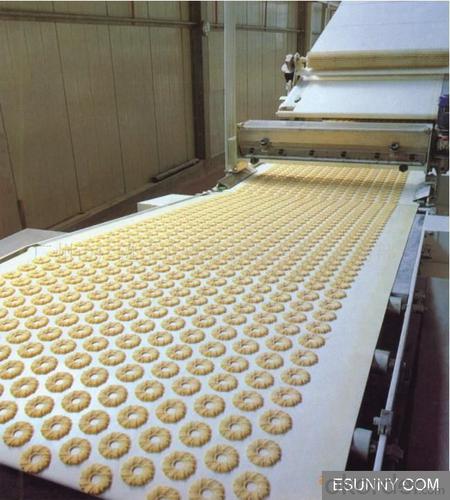

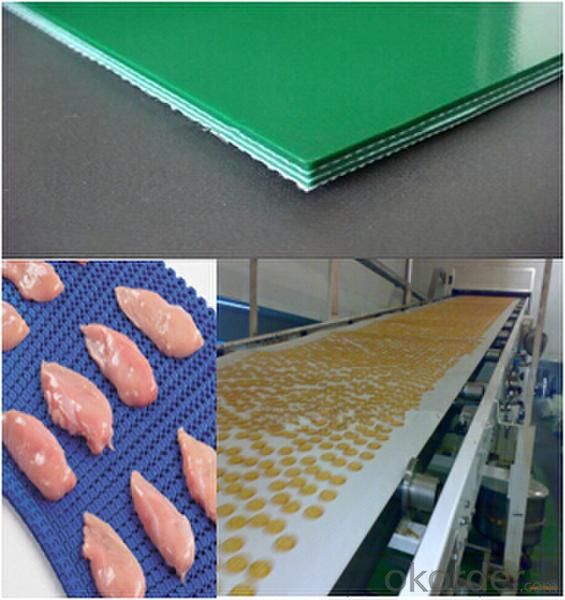

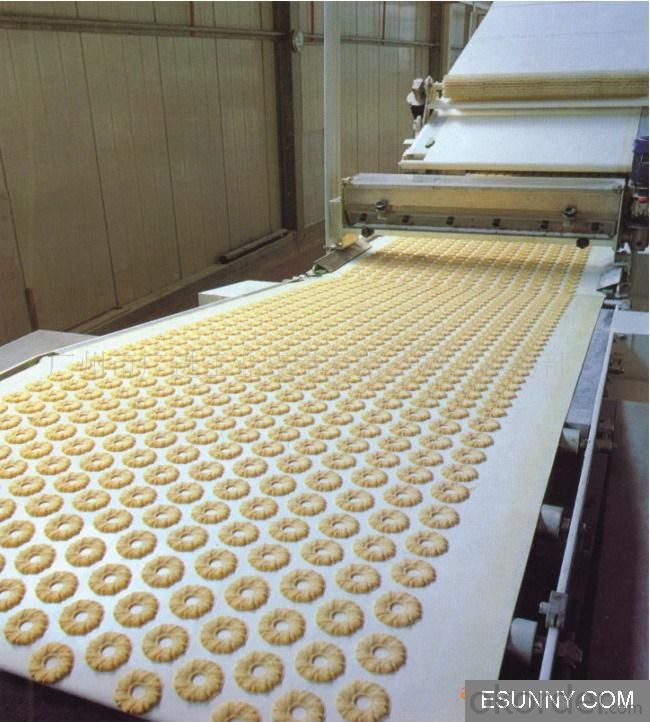

PVC Conveyor Belt Light Duty Food Grade White Food Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt Light Duty Food Grade

Applications & features:

Ø Especially suitable for material conveying at inflammable of underground coal mines.

Ø The fabric is high in strength , with low elongation, light carcass, shock resistant, anti-tear and good in trough ability.

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Various surfaces with high, medium, and low coefficient friction

Dimensional stability

Less noise

PVC Solid Woven Conveyor Belt:

Ø Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Ø Cover thickness can be from 0.5 to 4mm.

Ø Nitrile covered PVG type

Ø Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 18mm.

Ø Resistance to wetness, slip, low temperature and wear resistance of the belt.

- Q: How does rubber mobile phone cover change yellow?

- Now there is no good solution to this phenomenon, rubber oxidation caused, it is recommended to replace the new mobile phone sets. Rubber products gradually appear, become yellow, harden and become brittle, with the increase of service time. This is an irreversible process.

- Q: Silicone is silicone rubber? Extracted from there?

- Inorganic silica gel is a kind of highly active adsorbent material, which is usually reacted with sodium silicate and sulfuric acid, followed by a series of post treatment processes such as aging and acid foaming.

- Q: Is the odour emitted by industrial rubber poisonous?

- The rubber shaped blank after extruding; and then the textile materials and rolled hanging glue or glue (or metal) together formed into semi-finished products; finally after vulcanization will have final semi-finished products made of high elastic plastic.Most of the ingredients are organic substances, volatile, containing toxic, harmful and highly carcinogenic NOBS.

- Q: How can rubber products prevent fading?

- Light and white rubber products are prone to yellowing in the course of use and storage, thus affecting appearance and quality, resulting in various economic disputes and irreversible losses.

- Q: Why do rubber products become so long that they seem to melt and become sticky on the surface?

- If the solvent is tacky, the reason why the rubber is not involved in the crosslinking is dissolved. Rubber products are generally crosslinked, and the crosslinked part is the main part of rubber. It only swells and dissolves under the action of solvent. If this is the case, it will not stick when the solvent is dry.

- Q: EPDM rubber foam?

- Chung Tian factory. EPDM rubber foam sponge is one of the best thermal insulation materials.

- Q: What are the bridge rubber air bags used for?

- The bridge is a kind of rubber bladder contraction, inflatable rubber bag, Yongsheng bridge hollow board internal mold is used to form the mold cavity concrete, prestressed concrete hollow slab in the mold is simple to use, safe and sanitary, simple operation, time saving, labor saving. The rubber gasbag is inflated for use, easy to use and convenient to remove after use, saves labor time and labor cost, and reduces work intensity.

- Q: Does the fuel pipe for automobiles belong to rubber products?

- If it is a diesel car, then the high pressure part of the metal pipe only, in the low pressure part of the rubber tube.

- Q: How to distinguish between plastic products and rubber products, toys?

- Temperature resistance, plastic, fire easily deformation, melting, rubber will not be deformed, it will not melt

- Q: What is the rubber composition and function of the airplane tyres?

- Ethylene propylene rubber and ethylene propylene rubber are synthesized with ethylene and propylene as main raw materials. They are resistant to aging, electrical insulation and ozone resistance. Ethylene propylene rubber can be filled with oil and filled with carbon black. The price of the product is low, and the chemical stability of the ethylene propylene rubber is good. The abrasion resistance, elasticity, oil resistance and the proximity of styrene butadiene rubber are close. Ethylene propylene rubber is widely used. It can be used as tyre, sidewall, rubber strip and inner tube, as well as parts of automobile. It can also be used as wire, cable sheath and high voltage and extra high voltage insulating material. Can also manufacture rubber shoes, sanitary products and other light colored products. It is a chloroprene rubber as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength, heat resistance, light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good. Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

Send your message to us

PVC Conveyor Belt Light Duty Food Grade White Food Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords