EP Fabric Rubber Conveyor Belt EP100-EP500 Plies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

EP Fabric Rubber Conveyor Belt EP100-EP500 Plies

Description of Rubber Conveyor Belt

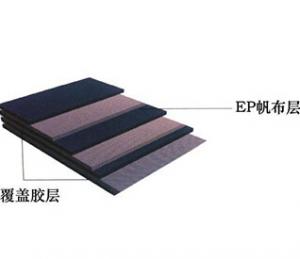

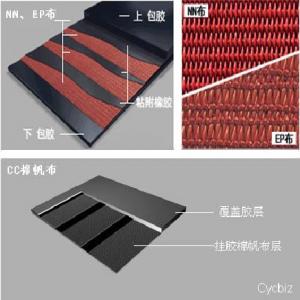

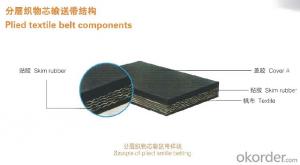

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildew-proof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

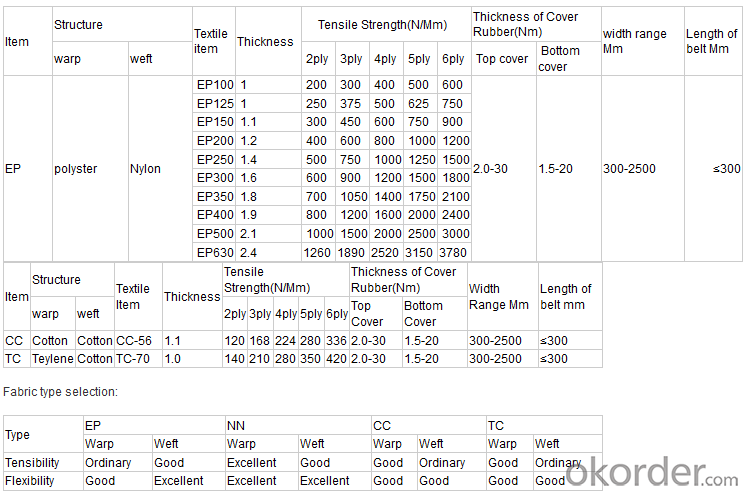

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

USAGE: mining, metallurgical industry and architectural industry, ports etc.

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: What is the cause of the bursting of rubber products and how should they be improved?

- There are five reasons for the bursting of rubber products: 1. forming temperature is too high, or the temperature of the upper and lower template is inconsistent. 2. the exhaust line is too open or exhaust time is too late. 3., the material quickly cooked. 4., the mold structure is irrational, there is no running trough. 5., down weight, overweight.

- Q: What are the causes of cracks in vulcanized rubber products?

- 1. Add some oil, 2. And reduce accelerator or vulcanizing agent 3., reduce the sulfidation temperature 4. After complete cooling

- Q: Excuse me, what is in the rubber rubber, glue them, what is the difference?

- The toughness greatly improved than rubber glue. If the car tire is cooked. Generally the same thickness, soft as glue.

- Q: How does the rubber part of the watch become yellow?

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q: The silica gel of the kettle is the white one that is waterproof and leaked out

- Isoprene rubber (IR) is a kind of CIS structural rubber polymerized from isoprene monomer. The chemical composition and solid structure are similar to those of natural rubber, and the properties are very close to natural rubber. Therefore, synthetic rubber is called. It has most of the advantages of natural rubber, aging resistance is better than natural rubber, elasticity and strength is slightly lower than natural rubber, poor processing performance, higher cost. Temperature range: about 50 DEG C + 100 can be used instead of natural rubber production of tires, rubber shoes, rubber hose, tape and other general products.

- Q: Can rubber products be injection molded and plastic injection functions?

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding. Die casting method. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q: The difference between plastic rubbers and rubber boots.

- Rubber boots will be oxidized and sun and high temperature can accelerate the aging of rubber products, make the hair soft and hard. Therefore, rainshoes must not long time sun, more do not insolate and roast. Also should avoid contact with coal sleeve, gasoline and other objects, because these chemical solvents can dissolve the rubber, the vamp is sticky. When wearing, do not cut with a broken glass, wire, nails and other sharp objects touch pinch, once you can not continue to use after shaving Water Leakage.

- Q: The action of various ingredients in rubber formula

- Performance system: reinforcing agent, colorant, foaming agent, fragrance agent, hardening agent, plasticizer, flame retardant, antistatic agent

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

- Q: What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The main use of natural rubber natural rubber because of its insulation, plasticity, water vapor barrier, tensile and wear characteristics of strong elasticity and good, widely used in industry, agriculture, national defense, traffic, transportation, machinery manufacturing, medical and health fields and daily life, such as transportation with the tire industry; with the transport belt, transmission belt, sealing rings; medical gloves, transfusion tube; used in the daily life of the shoes, raincoats, warm water bag are rubber as the main raw materials manufacturing, defense on the use of aircraft, artillery, tanks, and cutting-edge technology in the field of rockets, satellites, spacecraft, space shuttle requires a large amount of rubber parts.

Send your message to us

EP Fabric Rubber Conveyor Belt EP100-EP500 Plies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords