Tenax Biaxial Geogrids - Polypropylene Biaxial Tension Plastic Geogrid for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

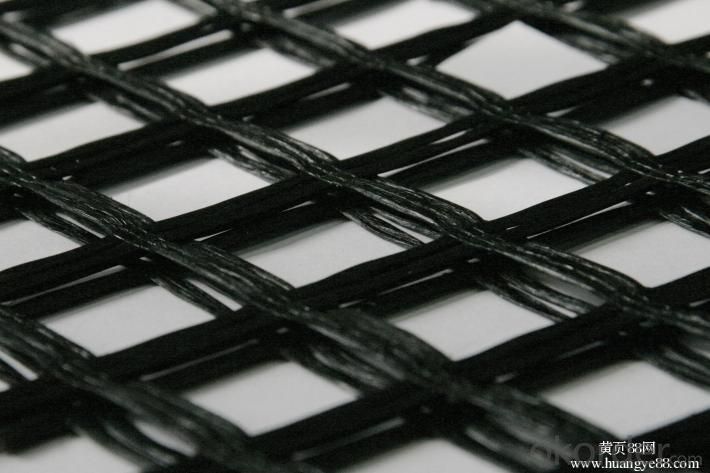

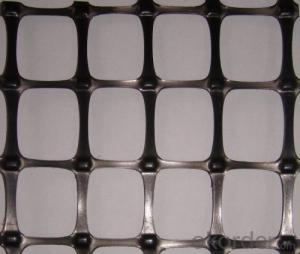

Structure of Polypropylene Biaxial Tension Plastic Geogrid

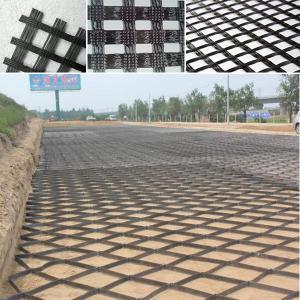

Polypropylene Biaxial Tension Plastic Geogrid is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle.This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed

Main Features of the Polypropylene Biaxial Tension Plastic Geogrid

High quality asphalt coation

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Polypropylene Biaxial Tension Plastic Geogrid Images

Polypropylene Biaxial Tension Plastic Geogrid Specification

Converting old cement concrete road into composite road.

Restraining reflection cracking caused by block shrinkage.

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Width:1 ~ 6m

Reinforcement of soft soil foundation and overall strength of roadbed

| Item | Tensile strength(KN/m) | Tensile strength at 2% elongation | Tensile strength at 5% elongation | Nomianal elongation | Products in the range of coal mine | ||

| TGSG15-15 | ≥15.0 | ≥5.0 | ≥7.0 | ≤15.0/13.0 | Fire out time from outer flam(s) | Surface resistivity | |

| TGSG20-20 | ≥20.0 | ≥7.0 | ≥14.0 | ≤3 | <1×109 | ||

| TGSG25-25 | ≥25.0 | ≥9.0 | ≥17.0 | ||||

| TGSG30-30 | ≥30.0 | ≥10.5 | ≥21.0 | ||||

| TGSG35-35 | ≥35.0 | ≥12.0 | ≥24.0 | ||||

| TGSG40-40 | ≥40.0 | ≥14.0 | ≥28.0 | ||||

| TGSG45-45 | ≥45.0 | ≥16.0 | ≥32.0 | ||||

| TGSG50-50 | ≥50.0 | ≥17.5 | ≥35.0 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the typical applications of geogrids in geotechnical engineering?

- Geogrids are commonly used in geotechnical engineering for various applications such as soil stabilization, reinforcement of retaining walls and slopes, erosion control, and pavement reinforcement. They provide mechanical support and increase the stability of soil structures, preventing soil movement and enhancing the overall performance of geotechnical projects.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength to the soil. These grid-like structures are placed within the levee's soil layers, creating a stable and cohesive system. The geogrids distribute the applied loads more evenly and prevent soil erosion, enhancing the overall stability and strength of the levee structure.

- Q: Should the municipal geogrid be included in the area of overlap, and, if necessary, the proportion of the area to be included?

- Per 1000 square meters of the amount of the project is a fixed amount of 1100 square meters (including the overlap and loss)

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- Glass fiber mesh used in exterior wall, interior wall paint, mainly to prevent cracking, different materials at the junction of mortar plastering material hollowing. Local node reinforcement will also be used.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing tensile strength and stabilizing the soil, preventing its movement and potential failure. The geogrids act as reinforcements that distribute the applied loads more evenly, reducing the stresses on the soil and improving its overall stability. Additionally, geogrids enhance the bearing capacity of the structure, increase its resistance to settlement, and minimize the potential for deformation or displacement.

- Q: How is the installation of geogrids carried out?

- The installation of geogrids is typically carried out by first preparing the subgrade, which involves clearing the area of any debris and ensuring a stable foundation. Then, the geogrid material is rolled out and placed on top of the subgrade. It is important to align the geogrid properly and ensure that it is not wrinkled or damaged during installation. Anchoring devices, such as spikes or staples, are then used to secure the geogrid to the subgrade. Finally, the geogrid is covered with the desired fill material, such as soil or aggregate, to complete the installation process.

- Q: What are the typical applications of geogrids?

- Geogrids are commonly used in various civil engineering applications. They are primarily used for soil stabilization, reinforcement, and erosion control in projects such as retaining walls, slopes, embankments, roadways, and pavements. Geogrids help improve the overall strength and stability of these structures by distributing loads, reducing lateral movement of soil, and preventing soil erosion.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are designed to withstand harsh environmental conditions, including high temperatures, moisture, and chemical exposure. Geogrids are made from high-strength materials, such as polyester or polypropylene, which provide resistance against degradation and maintain their structural integrity over time. They have a long service life and can effectively retain soil, stabilize slopes, and reinforce paved surfaces for many years without significant deterioration.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge abutments. Geogrids are commonly used in geotechnical engineering to enhance the stability and strength of soil structures, such as bridge abutments. They provide tensile strength and distribute loads, improving the overall performance and longevity of the structure.

- Q: How do geogrids enhance the stability of steep railway embankments?

- Geogrids enhance the stability of steep railway embankments by providing reinforcement and confinement to the soil. They are installed within the embankment to distribute the load more effectively, reducing lateral movement and preventing soil erosion. This additional support increases the embankment's resistance to slope failure, improving its overall stability and ensuring the safe operation of the railway.

Send your message to us

Tenax Biaxial Geogrids - Polypropylene Biaxial Tension Plastic Geogrid for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords