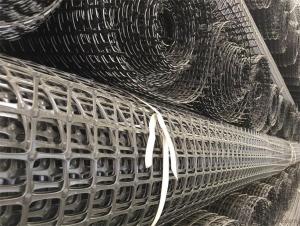

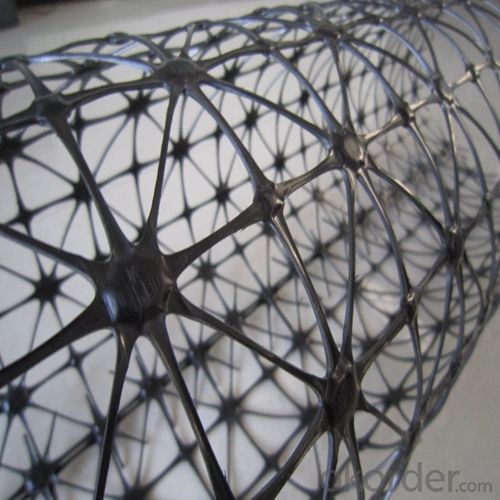

Tenax Biaxial Geogrids - Lightweight Biaxial Polypropylene Geogrid for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

EGA50-50, EGA80-80, EGA100-100

Material:

Fiberglass

Coating:

asphalt

feature:

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes. In case of water streams construction, geogrid application allows planting trees and shrubs along the banks protecting them from ablation. Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their strength and stability. They provide reinforcement and prevent the spreading of cracks and ruts, increasing the pavement's resistance to traffic loads. Additionally, geogrids help to distribute the load more evenly across the pavement, reducing the potential for deformation and extending its lifespan.

- Q: What are the general laying methods of Geogrid

- Along the longitudinal laying, U nail fixed joint part, 15 cm, with tie rods or connection

- Q: Can geogrids be used in slope stabilization for railway embankments with high water table conditions?

- Yes, geogrids can be used in slope stabilization for railway embankments with high water table conditions. Geogrids offer effective reinforcement and soil confinement, preventing soil erosion and enhancing the stability of the embankment even in areas with high water levels. They provide additional strength and support to the soil, reducing the risk of slope failure and improving the overall stability of the railway embankment.

- Q: What are the factors to consider when designing with geogrids for reinforced soil walls?

- When designing with geogrids for reinforced soil walls, several factors need to be considered. Firstly, the strength and stiffness of the geogrid material is crucial, as it should be able to provide adequate reinforcement to the soil. The type and characteristics of the soil being reinforced also play a significant role, as its properties, such as cohesion and angle of internal friction, impact the overall stability of the wall. Additionally, the design should consider the required wall height, slope angle, and the anticipated loads or surcharges that the wall will be subjected to. Proper installation techniques and construction quality control are also essential factors to ensure the effectiveness and long-term performance of the reinforced soil wall.

- Q: Is the test items within the inspection listAcceptance specification

- Overlapping width of Geogrid

- Q: Geogrid test items: what is the point of the joint point?

- The water penetration point of the lap joint is a testing project of geomembrane or waterproof board

- Q: What is the effect of cyclic loading on geogrid behavior?

- Cyclic loading on geogrid behavior can have detrimental effects, such as increased deformation and reduced strength over time. This repeated loading and unloading can lead to progressive damage and degradation of the geogrid, compromising its ability to provide reinforcement and stabilization. Therefore, it is important to consider the potential impact of cyclic loading when designing and implementing geogrids in construction projects.

- Q: What is the purpose of using the three - way geogrid in the gravel layer

- So that the crushed stone layer is more solid and meets the design requirements.

- Q: Can geogrids be used for reinforcement in asphalt overlays?

- Yes, geogrids can be used for reinforcement in asphalt overlays. Geogrids are commonly utilized to improve the overall performance and longevity of asphalt overlays by enhancing their tensile strength, reducing cracking and rutting, and providing structural support.

- Q: Can geogrids be used in reinforced earth bridge abutments?

- Yes, geogrids can be used in reinforced earth bridge abutments. Geogrids are commonly used in reinforced earth structures as they provide soil reinforcement and improve the stability and strength of the structure. In the case of bridge abutments, geogrids can be used to reinforce the soil backfill behind the abutment walls, enhancing its load-bearing capacity and reducing the potential for settlement or failure.

Send your message to us

Tenax Biaxial Geogrids - Lightweight Biaxial Polypropylene Geogrid for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords