Geogrids Fort Mcmurray Steel-Plastic Composite Geogrid for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

Structure of Steel-Plastic composite Geogrid for coal mine description :

Made of polypropylene and steel wire by extension technology after inflaming retarding and anti static treatment , it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Steel-Plastic composite Geogrid for coal mine:

Homogenous structure, low creepage ,anti-aging and resisting acid and alkaline.

Inflaming retarding , anti static ,long lifetime,high safety factor ,high bearing capacity

Application of of Steel-Plastic composite Geogrid for coal mine :

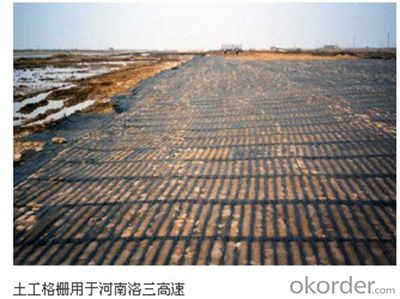

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Steel-Plastic composite Geogrid for coal mine

Single mesh belt pulling strength not less than 4000N

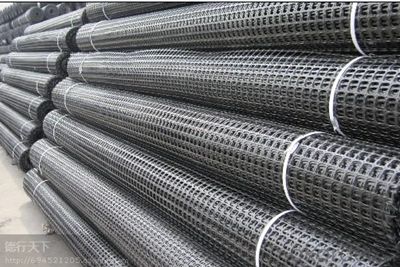

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Steel-Plastic composite Geogrid for coal mine Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Steel-Plastic composite Geogrid for coal mine : within 10 days after receiving the deposit

- Q: What is the role of geogrid?

- Unidirectional geogrid reinforcement for River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period. The geogrid reinforcement material constitutive model

- Q: What are the load-bearing capacities of geogrids?

- The load-bearing capacities of geogrids vary depending on the specific type and design of the geogrid, as well as the soil conditions and application. However, geogrids are typically engineered to have high tensile strength and can support heavy loads, ranging from several hundred to several thousand kilonewtons per meter.

- Q: How do geogrids improve the performance of unpaved roads?

- Geogrids improve the performance of unpaved roads by providing structural reinforcement and stabilization. They help distribute the load from traffic and prevent the aggregate material from shifting or rutting. This increases the overall strength and durability of the road, reducing maintenance needs and increasing its lifespan.

- Q: Water conservancy projects, the construction of the geogrid used in the quota which is not, how should the set of fixed price calculation of geogrid?

- Per 1000 square meters of the amount of the project is a fixed amount of 1100 square meters (including the overlap and loss)

- Q: Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are typically made from high-strength polymers like polyester or polypropylene, which have excellent chemical resistance properties. This allows geogrids to withstand exposure to various chemicals commonly found in soil, water, and other environmental conditions, making them a reliable option for reinforcement and stability in different applications.

- Q: Want to know what is the advantage of unidirectional polyester geogrid and two-way existence? What are the differences between the two?For example, function, cost, construction

- Different intensity

- Q: What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, making them suitable for applications requiring reinforcement in a single direction. Biaxial geogrids, on the other hand, have strength and stiffness in two perpendicular directions, allowing for reinforcement in multiple directions. This makes biaxial geogrids more versatile and applicable to a wider range of projects.

- Q: Geogrid specification TGSG40-40 what meaning

- I would like to tell you about, TGSG40-40: biaxial tensile plastic geogrid, the vertical and horizontal strength indicators are not less than 40KN, to meet the national standards.

- Q: How do geogrids improve the performance of reinforced slopes?

- Geogrids enhance the performance of reinforced slopes by providing increased stability and strength. They act as a reinforcement layer within the soil, distributing loads more evenly and reducing the risk of slope failure or erosion. Geogrids also improve the soil's shear strength, preventing lateral movement and improving overall slope stability.

- Q: Can geogrids be used in mining and landfill applications?

- Yes, geogrids can be used in mining and landfill applications. Geogrids are commonly used in these industries to reinforce soil and provide stability to slopes, embankments, and retaining walls. They can enhance the strength and load-bearing capacity of the soil, making them suitable for various mining and landfill applications.

Send your message to us

Geogrids Fort Mcmurray Steel-Plastic Composite Geogrid for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords