Tabe Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

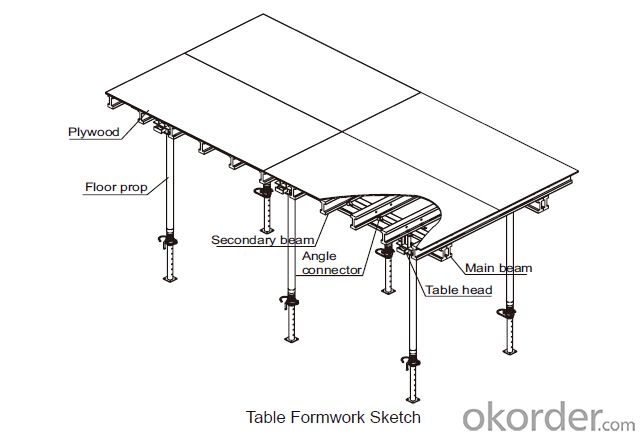

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel formwork be used for curved or complex shapes?

- Indeed, curved or complex shapes can be achieved using steel formwork. Steel, being a resilient and long-lasting material, can effortlessly be manipulated and molded to accommodate diverse designs. Its flexibility allows for the creation of intricate and personalized formwork systems suitable for a vast array of applications, including curved or complex shapes. The robustness and solidity of steel guarantee that the formwork remains steadfast throughout the pouring and setting of concrete, enabling meticulous and precise construction. Furthermore, the reusability of steel formwork proves to be an economical choice for projects necessitating curved or complex shapes.

- Q: Can steel formwork be used for concrete structures in corrosive environments?

- Steel formwork can be used for concrete structures in corrosive environments, but special precautions need to be taken to ensure its durability and longevity. Corrosive environments, such as those with high levels of moisture or exposure to chemicals, can cause steel to rust and deteriorate over time. To mitigate this risk, the steel formwork should be properly coated with corrosion-resistant materials, such as epoxy or galvanized coatings, to provide a protective barrier against the corrosive elements. Regular maintenance and inspections should also be carried out to identify and address any signs of corrosion or damage. Additionally, alternative formwork materials, such as plastic or fiber-reinforced polymers, may be more suitable for extremely corrosive environments as they offer superior resistance to corrosion. Ultimately, the decision to use steel formwork in a corrosive environment should be based on thorough evaluation of the specific conditions and the implementation of appropriate preventive measures to ensure the long-term durability of the concrete structure.

- Q: What are the maintenance requirements for steel formwork?

- The maintenance requirements for steel formwork typically involve regular cleaning to remove any debris or concrete buildup, inspection for signs of wear or damage, and occasional repairs or replacement of damaged components. Additionally, applying a protective coating or rust inhibitor can help prevent corrosion and prolong the lifespan of the formwork.

- Q: How does steel formwork handle different concrete early age strength development?

- Steel formwork, a versatile and durable material commonly used in construction for shaping and supporting concrete structures, offers several advantages when dealing with different concrete early age strength development. To begin with, during the initial stages of the concrete's curing process, steel formwork provides exceptional support and stability. This is critical as the concrete gains strength and begins to solidify. The inflexible nature of steel formwork prevents any distortion or displacement, ensuring that the concrete maintains its desired shape and structure as it sets. Moreover, steel formwork guarantees a high level of dimensional accuracy. This allows for precise and consistent shapes and sizes of the concrete elements being constructed. This is particularly significant during the early age strength development phase, as any variations or irregularities in the formwork could have a negative impact on the overall strength and integrity of the concrete. Additionally, steel formwork exhibits high resistance to moisture and chemical reactions. Concrete undergoes a hydration process, where it absorbs water and undergoes chemical reactions to gain strength. Since steel formwork is non-absorbent, it prevents excessive moisture from being absorbed by the concrete, which could hinder strength development or cause cracks. Furthermore, steel formwork does not chemically react with the concrete, ensuring that the desired early age strength development is not compromised. Another advantage of steel formwork is its reusability. Unlike other formwork materials like wood or plastic, steel formwork can be easily disassembled and reused for multiple construction projects. This not only reduces construction costs but also guarantees consistent and reliable formwork performance, regardless of the concrete's early age strength development requirements. In conclusion, steel formwork is a dependable and efficient solution for handling various concrete early age strength development tasks. Its stability, dimensional accuracy, resistance to moisture and chemical reactions, and reusability make it an ideal choice for shaping and supporting concrete structures during the crucial initial stages of curing.

- Q: How does steel formwork affect the overall sound insulation of a structure?

- Steel formwork has a significant impact on the overall sound insulation of a structure. Due to its dense and rigid nature, steel formwork tends to transmit sound vibrations more efficiently compared to other materials such as wood or plastic. This means that if steel formwork is used extensively in a building's construction, it can potentially reduce the sound insulation capabilities of the structure. The transmission of sound through steel formwork occurs mainly through three mechanisms: airborne sound, impact sound, and structure-borne sound. Airborne sound refers to sound waves traveling through the air and being transmitted through the steel formwork. Impact sound occurs when a sound wave hits the steel surface, causing it to vibrate and transmit the sound further. Structure-borne sound refers to vibrations traveling through the steel formwork and being transmitted to other parts of the building. To mitigate the negative impact of steel formwork on sound insulation, various measures can be taken. One approach is to use additional sound-absorbing materials, such as acoustic panels or insulation, on the interior surfaces of the structure. These materials can help reduce the transmission of airborne sound waves and dampen the vibrations caused by impact or structure-borne sound. Additionally, proper sealing and jointing of the formwork can minimize the leakage of sound through gaps or cracks. It is important to note that the overall sound insulation of a structure is not solely dependent on the formwork material. Other factors, such as the thickness of walls, type of insulation used, and the design of windows and doors, also play a crucial role. Therefore, while steel formwork may have a negative impact on sound insulation, it is possible to compensate for this by employing appropriate acoustic design strategies and incorporating soundproofing techniques throughout the building's construction process.

- Q: How does steel formwork contribute to the sustainability of a construction project?

- Steel formwork contributes to the sustainability of a construction project in several ways. Firstly, steel formwork is highly durable and has a long lifespan. This means that it can be used for multiple construction projects, reducing the need for new formwork and minimizing waste. Additionally, the durability of steel formwork reduces the need for frequent repairs or replacements, saving both time and resources. Secondly, steel formwork is a reusable material. It can be easily disassembled and reassembled for use in different projects, reducing the demand for new formwork and minimizing the amount of waste generated. This significantly reduces the environmental impact of construction projects, as it reduces the need for new materials and decreases the amount of waste sent to landfills. Furthermore, steel formwork is highly efficient and allows for faster construction times. Its strength and stability enable the construction process to progress more quickly, reducing the overall duration of the project. This not only saves time but also reduces the energy consumption associated with construction activities, contributing to the overall sustainability of the project. Moreover, steel formwork is a recyclable material. At the end of its lifespan, the steel formwork can be recycled, further reducing its environmental impact. Recycling steel requires less energy and resources compared to manufacturing new steel, thus reducing greenhouse gas emissions and conserving natural resources. In summary, steel formwork contributes to the sustainability of a construction project by being durable, reusable, efficient, and recyclable. It reduces the need for new formwork, minimizes waste generation, saves construction time, and conserves resources. By incorporating steel formwork into construction projects, builders can significantly reduce the environmental impact while ensuring long-term durability and efficiency.

- Q: What are the different types of reinforcement used with steel formwork?

- There are several types of reinforcement used with steel formwork in construction projects. The choice of reinforcement depends on various factors such as the load-bearing capacity required, the type of structure being built, and the environmental conditions. 1. Steel Bars: Steel bars, also known as rebars, are the most commonly used reinforcement in steel formwork. These bars are typically made of carbon steel and are available in various diameters and lengths. Steel bars provide strength and stability to the formwork, ensuring that it can withstand the applied loads. 2. Wire Mesh: Wire mesh is another widely used reinforcement in steel formwork. It is made by interweaving or welding steel wires to form a grid-like pattern. Wire mesh provides additional tensile strength to the formwork, making it more resistant to cracking and deformation. 3. Steel Fibers: Steel fibers are small, discrete fibers made of steel that are added to the concrete mix. These fibers enhance the tensile strength and ductility of the concrete, making it more resistant to cracking and improving its overall structural performance. 4. Reinforcing Plates: Reinforcing plates are flat steel plates that are used to reinforce specific areas of the formwork. These plates are typically welded or bolted to the formwork structure to provide additional strength and stability. 5. Tie Rods: Tie rods are used to secure and reinforce the formwork panels. These rods are usually made of steel and are inserted through holes in the formwork panels. They are then tightened with nuts and washers to hold the panels in place and prevent them from moving or deforming. 6. Steel Frames: Steel frames are used in larger formwork systems to provide structural support and stability. These frames are typically made of steel beams and columns and are assembled to form a rigid structure. Steel frames are commonly used in high-rise building construction and other large-scale projects. Overall, the different types of reinforcement used with steel formwork play a crucial role in ensuring the strength, stability, and durability of the formwork system. The choice of reinforcement depends on the specific requirements of the project and the desired structural performance.

- Q: What are the considerations when designing steel formwork for underground utilities?

- There are several essential factors to consider when designing steel formwork for underground utilities. These considerations encompass: 1. Structural Integrity: It is necessary to ensure that the formwork can withstand the pressure and forces exerted by the surrounding soil and any potential external loads. The design should offer sufficient strength and stability throughout the construction process. 2. Water and Chemical Resistance: Underground utilities are often exposed to water and various chemicals. Consequently, the formwork must be designed to resist corrosion and deterioration caused by these elements, ensuring its durability. 3. Accessibility for Installation and Maintenance: The formwork design should facilitate easy access during installation and future maintenance activities. This may involve incorporating provisions for openings, removable sections, or access points to allow workers to easily reach the utilities when necessary. 4. Modular Design: Utilizing a modular design can provide flexibility and simplify installation. Modular formwork systems enable quick assembly and disassembly, which proves advantageous when dealing with different underground utility layouts and configurations. 5. Safety: Safety is of utmost importance in any construction project. Therefore, the formwork design should include safety features such as guardrails, handrails, and anti-slip surfaces to minimize the risk of accidents and injuries during construction and maintenance. 6. Cost-effectiveness: The design should strike a balance between performance and cost. It should be optimized to minimize material usage and labor costs while maintaining quality and durability. 7. Compatibility with other construction methods: The design should be compatible with other construction methods and materials used for the underground utilities. This encompasses considerations for joining techniques, such as welding or bolting, and compatibility with other materials, such as concrete or PVC pipes. By taking these factors into account, designers can ensure that the steel formwork for underground utilities is structurally sound, resistant to environmental factors, easily accessible for installation and maintenance, safe for workers, cost-effective, and compatible with other construction methods.

- Q: How does steel formwork affect the overall water tightness of a structure?

- Steel formwork does not directly affect the water tightness of a structure as it is used to create the shape and support the concrete during construction. However, the quality of the concrete and the proper installation of seals, joints, and waterproofing measures are crucial factors determining the overall water tightness of the structure.

- Q: Can steel formwork be used for elevated water tanks?

- Indeed, elevated water tanks can be constructed using steel formwork. This particular formwork option proves to be versatile and long-lasting, offering a durable solution for the construction of such tanks. The strength and stability it provides are crucial in supporting the weight of both the tank and the water it holds. Furthermore, the use of steel formwork allows for the creation of intricate shapes and designs, granting the flexibility to tailor the tank according to specific requirements. Moreover, steel formwork exhibits remarkable resistance against weather conditions and corrosion, rendering it suitable for extended use in outdoor settings. All in all, steel formwork emerges as a dependable choice for erecting elevated water tanks, ensuring structural integrity and safeguarding the functionality and safety of the water storage system.

Send your message to us

Tabe Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords