Structural Steel Square Bars S30C Carbon Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structural Steel Square Bars S30C Carbon Steel Specification 1, Size: 120*120mm; 130*130mm; 150*150mm; 160*160mm; 200*200mm 2, Length: Max 12m 3, Heat Treatment: Normalizing, Annealing, Tempering, Quenching 4, Surface Treatment: Black, Polished, Galvanized Application 1, Used in mending drawing parts of panel die of automotive sheet metal & stamping die of large metal sheet. 2, Used in making hard surface. 3, Used as base plate of cold mold. 4, Used as fixed plate of drill jig. Chemical Composition % Products Show C Si Mn P S Cr Ni Cu 0.27-0.34 0.17-0.37 0.50-0.80 ≤0.035 ≤0.035 ≤0.25 ≤0.30 ≤0.25

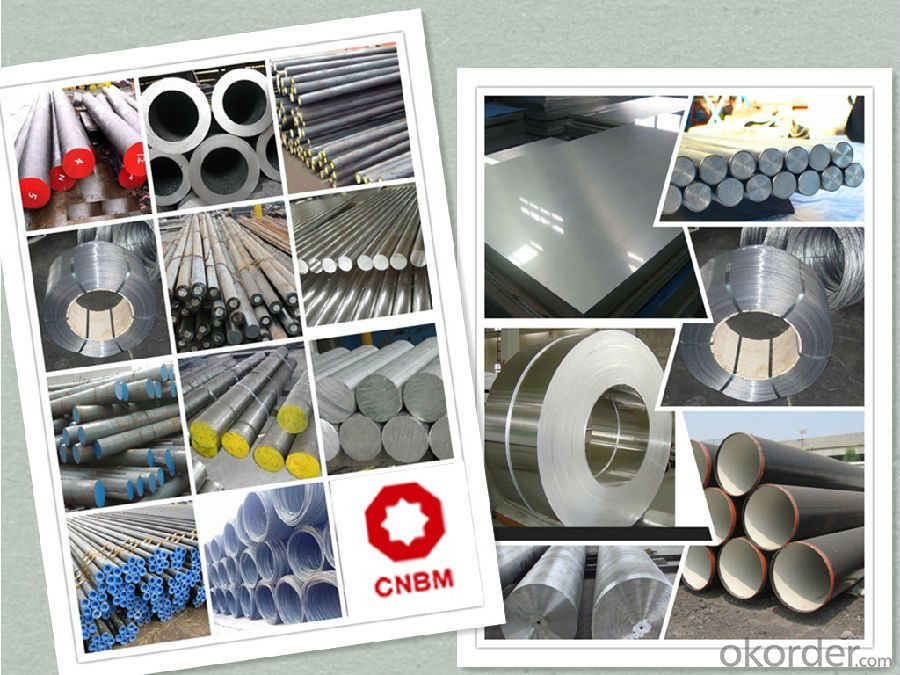

Work Shop

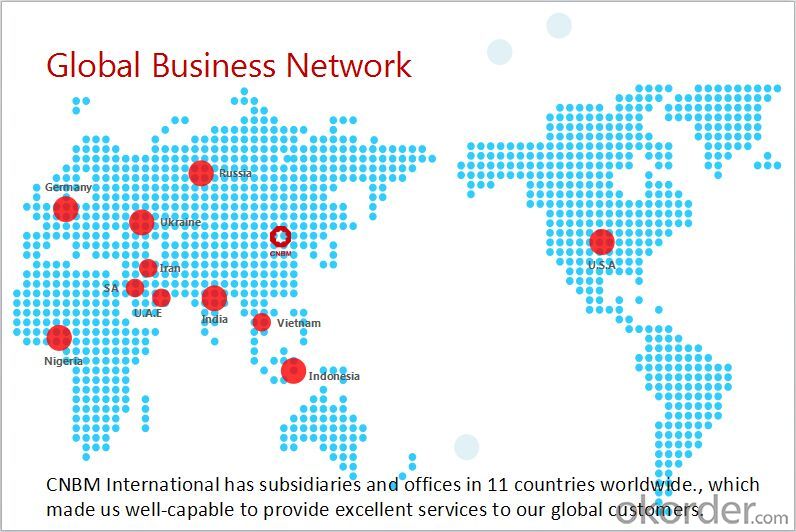

About Us

- Q: Can a steel square be used for checking the squareness of a shelf?

- Yes, a steel square can be used for checking the squareness of a shelf. A steel square is a reliable tool for measuring right angles and can be used to ensure that the corners of the shelf are perfectly square.

- Q: Can a steel square be used for checking the alignment of fences?

- Yes, a steel square can be used for checking the alignment of fences. A steel square is a versatile tool that can be used for various measurements and alignments. When it comes to checking the alignment of fences, a steel square can help ensure that the fence posts are square to the ground and that the fence panels are properly aligned. By placing the steel square against the posts and panels, one can easily determine if they are straight and aligned correctly. The right angles and straight edges of the steel square make it an effective tool for this purpose.

- Q: How do you use a steel square for marking roof dormer angles?

- To use a steel square for marking roof dormer angles, first, position the square on the edge of the roof, aligning one leg with the roof's pitch. Then, rotate the square until the other leg matches the desired angle for the dormer. Finally, mark the angle on the roof using a pencil or marker, ensuring accurate measurements for the dormer construction.

- Q: Can a steel square be used for checking the levelness of countertops?

- No, a steel square cannot be used for checking the levelness of countertops. A steel square is primarily used for measuring angles and ensuring the accuracy of right angles. To check the levelness of countertops, a level tool should be used. A level is a device with a bubble vial filled with liquid that allows you to determine if a surface is perfectly horizontal or vertical. This is important for countertops to ensure that they are level and provide a stable and even surface.

- Q: Can a steel square be used for cabinet-making projects?

- Yes, a steel square can be used for cabinet-making projects. Steel squares are commonly used by woodworkers to ensure accurate and precise measurements and angles when building cabinets. They are sturdy, reliable, and can help in achieving straight cuts, proper joint alignments, and square corners while constructing cabinets.

- Q: Can a steel square be used for checking the alignment of a bandsaw table?

- Yes, a steel square can be used for checking the alignment of a bandsaw table. A steel square is a versatile tool that can be used for measuring and checking the squareness and alignment of various surfaces and objects. When it comes to a bandsaw table, a steel square can be placed against the table surface and the blade, allowing you to visually check if the blade is parallel to the table or if it is tilted. This is an important aspect of bandsaw operation as a misaligned blade can lead to inaccurate cuts and potential safety hazards. By using a steel square, you can quickly and easily determine if any adjustments need to be made to ensure the proper alignment of the bandsaw table.

- Q: Can a steel square be used for gazebo construction?

- Gazebo construction can indeed benefit from the utilization of a steel square. These versatile tools serve multiple purposes such as angle measurement, marking, ensuring squareness, and facilitating precise and accurate construction. Carpenters and builders frequently employ steel squares in various construction projects, including the construction of gazebos. By implementing a steel square, one can effectively establish and mark the necessary angles and cuts for the gazebo frame, guaranteeing proper alignment and squareness of the structure. Furthermore, during the assembly process, the steel square can be employed to verify squareness, thereby ensuring compliance with the desired specifications. In conclusion, a steel square is an invaluable tool that contributes significantly to the success of gazebo construction.

- Q: How do you use a steel square to measure the width of a door frame?

- To use a steel square to measure the width of a door frame, place the square against the inside edge of the door frame, ensuring it is aligned with the top and bottom. Then, read the measurement on the edge of the square to determine the width of the door frame.

- Q: How do you use a steel square to find the length of a stair stringer?

- In order to determine the length of a stair stringer using a steel square, a series of steps must be followed. Initially, position the steel square against the edge of the stringer board, ensuring that the long arm of the square is aligned with the board's edge. Then, extend the short arm of the square along the face of the stringer, aligning it with the rise and run measurements of the stairs. The rise represents the vertical distance between each step, while the run represents the horizontal distance. Once the square is properly aligned, make a mark on the stringer where the long arm intersects with the edge of the board. This mark signifies the length of the stringer. Repeat this procedure for every step, ensuring accurate measurement and marking of each stringer. Lastly, connect all the marks using a straight edge or a chalk line to form the outline of the stringer. This outline will serve as a guide when cutting the stringer to the correct length. Prior to making any cuts, it is essential to double-check your measurements and calculations to ensure accuracy.

- Q: Can a steel square be used for deck railing installation?

- Yes, a steel square can be used for deck railing installation.

Send your message to us

Structural Steel Square Bars S30C Carbon Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords