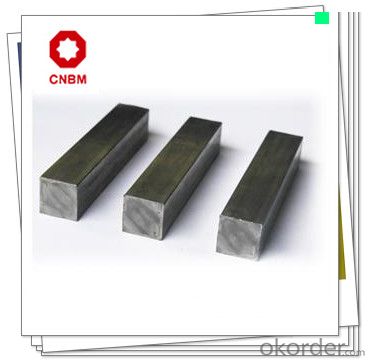

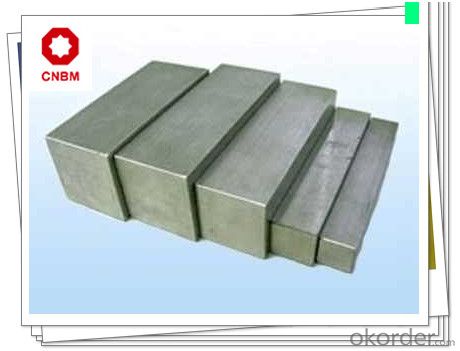

Carbon Structural Steel Square Bars ST37-2CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars ST37-2CR

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr |

| ST37-2CR | 0.21-0.25 | ≤0.35 | ≤1.4 | ≤0.045 | ≤0.045 | ≥0.30 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Impact AKv |

| 340-470 Mpa | ≥235 Mpa | ≥27J |

3, Diameter: 9mm, 9.8mm, 10mm, 12mm, 12.5mm, 13mm, 15mm, 15.87mm, 16mm, 19mm, 20mm, 22mm,

25mm, 25.4mm, 28mm, 38mm, 50mm, 51.5mm, 53mm, 65mm, 75mm, 100mm

Application

1, Widely used in construction and engineering structure.

2, Widely used in making reinforcing steel bar or building plant room rack, high voltage transmission tower, bridge, vehicle, boiler, vessel, ship, etc.

3, Widely used in manufacturing mechanical parts which are not required to be with high performance.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

Product Show

Work Shop

About Us

- Q: What is the difference between a bright and a cold finished steel round bar?

- Two distinct types of steel bars are the bright steel round bar and the cold finished steel round bar. These bars differ in their manufacturing processes and resulting characteristics. The bright steel round bar, also known as a turned or polished bar, undergoes a process called turning or polishing. During this process, a lathe machine rotates the rough steel bar while a cutting tool removes its outer layer. This results in a smooth and shiny surface, enhancing the bar's appearance, dimensional accuracy, and surface finish. Bright steel round bars are commonly used in applications where aesthetics and a high-quality surface finish are important, such as architectural components, decorative items, and certain automotive parts. On the other hand, the cold finished steel round bar undergoes a different manufacturing process called cold drawing or cold rolling. This process involves passing the hot-rolled steel bar through a series of dies at room temperature. As a result, the bar's diameter is reduced while its length is increased. This cold working process improves the mechanical properties of the steel bar, including increased tensile strength, improved yield strength, and enhanced dimensional accuracy. Cold finished steel round bars are often used in applications that require high strength and precision, such as shafts, gears, bolts, and tools. In conclusion, the main distinction between the bright steel round bar and the cold finished steel round bar lies in their manufacturing processes and resulting characteristics. The bright steel round bar is turned or polished to achieve a smooth and shiny surface, while the cold finished steel round bar undergoes cold drawing or rolling to enhance its mechanical properties and dimensional accuracy. The choice between these two types of steel bars depends on the specific requirements of the application, such as the need for aesthetics, surface finish, strength, or precision.

- Q: What is the tensile strength of round steel bars of diameter 28?

- The tensile strength of round steel bars of diameter 28 is 27079.36~33849.2 kg. It is explained as follows: the material of rebar is generally Q235-A carbon structural steel, its yield strength is 235 MPa, tensile strength is 441~550 MPa, and it is 44~55 kg / mm2. The cross-sectional area of 28 mm in diameter is about 615.44 mm2, and its tensile strength is about 27079.36~33849.2 kg.

- Q: How are steel round bars used in the construction of high-rise buildings?

- Steel round bars are commonly used in the construction of high-rise buildings due to their strength, durability, and versatility. These bars are typically made of carbon steel, which has excellent mechanical properties and can withstand high loads and pressures. In the construction of high-rise buildings, steel round bars are primarily used in reinforced concrete structures. They are commonly used as reinforcement in concrete beams, columns, and slabs. The bars are embedded in the concrete to provide additional strength and stiffness to the overall structure. One of the main advantages of using steel round bars is their ability to resist tension forces. Concrete is strong in compression but weak in tension, so the steel bars act as tension reinforcement, preventing the concrete from cracking or failing under tension loads. This helps to enhance the structural integrity and overall safety of the building. Additionally, steel round bars can be easily bent, shaped, and welded, allowing for flexible design and construction possibilities. They can be customized to specific lengths and diameters to suit the requirements of the building project. This versatility makes them ideal for constructing various structural elements, such as beams and columns, which need to be precisely engineered to support the weight and stresses of a high-rise building. Moreover, steel round bars have excellent resistance to corrosion, which is crucial in the construction of high-rise buildings that are exposed to various environmental elements. The corrosion-resistant properties of steel ensure the long-term durability and lifespan of the structure. Overall, steel round bars play a vital role in the construction of high-rise buildings by providing strength, durability, and flexibility to the reinforced concrete structures. They enhance the overall structural integrity, safety, and longevity of the building, making them an essential component in modern construction practices.

- Q: What are the different shapes available in steel round bars?

- Steel round bars are available in a variety of shapes, each designed to meet specific needs and applications. Some of the common shapes of steel round bars include: 1. Round: This is the most common and basic shape of steel round bars. It has a circular cross-section and is widely used in various industries for applications such as construction, manufacturing, and engineering. 2. Square: Square steel round bars have a square cross-section, making them suitable for applications that require stability and structural strength. They are commonly used in the construction of frames, supports, and braces. 3. Hexagonal: Hexagonal steel round bars have six flat sides and are often used in applications that require better grip and torque resistance, such as in machinery and tools. The hexagonal shape allows for a more secure connection and prevents slippage. 4. Flat: Flat steel round bars have a rectangular cross-section with two flat sides. They are commonly used for structural applications, such as in building frames and supports, as well as in the manufacturing of machinery and equipment. 5. Half-round: Half-round steel round bars have a semi-circular cross-section with one flat side. They are often used as decorative elements in architecture and furniture, as well as in the construction of railings and handles. 6. Oval: Oval steel round bars have an elongated oval shape, providing a unique aesthetic appeal. They are commonly used in decorative applications, such as in the design of furniture, railings, and artistic structures. Overall, the availability of different shapes in steel round bars allows for versatility in various industries, enabling engineers, manufacturers, and designers to choose the most suitable shape based on their specific requirements.

- Q: Are steel round bars suitable for welding?

- Certainly! Welding can be done with steel round bars, as they possess exceptional strength and durability. These bars are frequently utilized in welding applications due to their excellent properties. One can easily employ a variety of welding techniques, including MIG, TIG, or stick welding, to weld steel round bars. However, it is vital to carefully select the appropriate welding method and consumables based on the specific grade and alloy composition of the bar to ensure a successful weld. To achieve reliable and robust welds, proper surface preparation and cleaning are of utmost importance. All in all, steel round bars are a favored choice for welding projects due to their versatility and ability to endure high temperatures and stress.

- Q: Are steel round bars suitable for decorative purposes?

- Yes, steel round bars can be suitable for decorative purposes. They can be used in various architectural and interior design applications to create a modern and industrial aesthetic. Steel round bars can be shaped, polished, or painted to enhance their decorative appeal and add a stylish touch to furniture, fixtures, sculptures, and other artistic creations.

- Q: Are steel round bars suitable for agricultural applications?

- Yes, steel round bars are suitable for agricultural applications. They possess strong structural integrity, durability, and resistance to corrosion, making them ideal for various agricultural uses such as fencing, livestock handling equipment, and machinery parts. The versatility and reliability of steel round bars make them a popular choice in the agricultural industry.

- Q: Can steel round bars be used for making agricultural equipment?

- Yes, steel round bars can be used for making agricultural equipment. Steel round bars are known for their high strength and durability, making them suitable for heavy-duty applications in the agricultural industry. They can be used to manufacture various agricultural equipment such as plows, tillers, cultivators, harrows, and seeders. The strength of steel round bars allows these equipment to withstand the harsh conditions in the field, including the impact of rocks and hard soil. Additionally, steel round bars can be easily shaped and welded, providing flexibility in designing and customizing agricultural equipment according to specific requirements. Overall, steel round bars are a reliable and cost-effective material choice for making agricultural equipment due to their strength, durability, and versatility.

- Q: How do steel round bars compare to wrought iron bars?

- Steel round bars and wrought iron bars have several differences that set them apart. Firstly, steel round bars are made from an alloy of iron and carbon, whereas wrought iron bars are composed of pure iron with a low carbon content. This difference in composition leads to varying properties. Steel round bars are known for their strength and durability, making them suitable for a wide range of applications, including construction, manufacturing, and engineering. On the other hand, wrought iron bars are softer and more malleable, allowing them to be easily shaped and formed into intricate designs. This characteristic makes wrought iron bars popular in decorative applications such as gates, fences, and ornamental pieces. Another difference lies in their manufacturing processes. Steel round bars are typically produced through hot rolling, which involves heating the steel billet and passing it through a series of rollers to shape it into the desired round bar form. In contrast, wrought iron bars are made through a labor-intensive process called blacksmithing. This involves heating the iron and repeatedly hammering it to remove impurities and create a fibrous structure, resulting in its characteristic grainy appearance. In terms of cost, steel round bars are generally more affordable compared to wrought iron bars. The manufacturing process for steel is more streamlined and efficient, leading to lower production costs. Wrought iron bars, on the other hand, require more time and labor, making them more expensive. Finally, when it comes to corrosion resistance, steel round bars have an advantage. Steel can be further alloyed with elements such as chromium, nickel, and molybdenum to enhance its resistance to rust and corrosion. This makes steel round bars suitable for outdoor applications where they may be exposed to moisture and harsh environmental conditions. Wrought iron bars, although they possess some level of corrosion resistance, are more prone to rusting and require regular maintenance to prevent deterioration. In conclusion, steel round bars and wrought iron bars differ in terms of composition, strength, manufacturing process, cost, and corrosion resistance. The choice between the two will depend on the specific requirements of the application, with steel round bars being favored for their strength and affordability, while wrought iron bars are often chosen for their malleability and decorative appeal.

- Q: What are the advantages of using heat-resistant steel round bars?

- There are several advantages of using heat-resistant steel round bars. Firstly, heat-resistant steel round bars are specifically designed to withstand high temperatures without losing their mechanical properties. This means they can maintain their strength and structural integrity even in extreme heat conditions. Secondly, heat-resistant steel round bars have excellent corrosion resistance. This makes them highly durable and suitable for use in environments where they may be exposed to corrosive substances or chemicals. Their resistance to corrosion ensures a longer lifespan and reduces the need for frequent maintenance or replacement. Additionally, heat-resistant steel round bars have superior thermal conductivity. This property allows them to efficiently transfer heat, which can be beneficial in various applications. For example, in industries like power generation or petrochemicals, where heat transfer is crucial, using heat-resistant steel round bars ensures optimal performance and energy efficiency. Furthermore, heat-resistant steel round bars offer excellent dimensional stability. Even when subjected to high temperatures, they maintain their shape and size without warping or deforming. This property is particularly important in applications where precise measurements and tight tolerances are required. Lastly, heat-resistant steel round bars are readily available in various sizes and grades, offering versatility in their applications. They can be used in a wide range of industries such as aerospace, automotive, construction, and manufacturing, where high temperatures are involved. In conclusion, the advantages of using heat-resistant steel round bars include their ability to withstand high temperatures, excellent corrosion resistance, superior thermal conductivity, dimensional stability, and versatility in applications. These benefits make them an ideal choice for industries requiring materials that can perform reliably under extreme heat conditions.

Send your message to us

Carbon Structural Steel Square Bars ST37-2CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords