Carbon Structural Steel Square Bars SS400CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars SS400CR

Product Specification

1, p ≤0.050%; S ≤0.050%; Cr ≥0.30%

2, Strength of Extension σb ≥400 Mpa

Yield Strength σs ≥245(25) Mpa

Application

1, Widely used in construction and engineering structure.

2, Widely used in making reinforcing steel bar or building plant room rack, high voltage transmission tower, bridge, vehicle, boiler, vessel, ship, etc.

3, Widely used in manufacturing mechanical parts which do not require high performance.

4, SS400CR with grade C or D can be used as steel with special use.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, bright, polished, galvanized

3, Product Process: hot rolled, cold drawn, forged

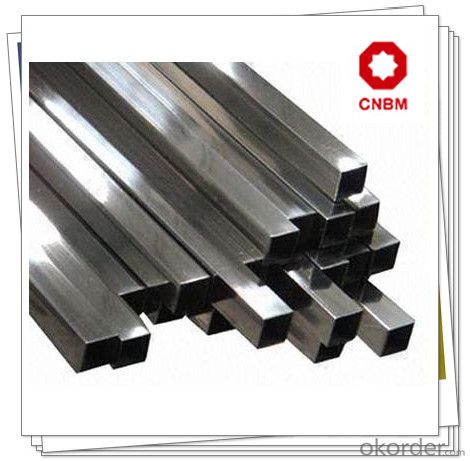

Product Show

Work Shop

About Us

- Q: Are steel round bars susceptible to cracking?

- Yes, steel round bars can be susceptible to cracking under certain conditions. Cracking can occur due to factors such as excessive stress, improper handling, or poor manufacturing processes. However, the susceptibility to cracking can be minimized by using high-quality steel, proper heat treatment, and careful handling and installation techniques.

- Q: Can steel round bars be used for structural purposes?

- Indeed, steel round bars have the capability to serve structural purposes. Due to their robustness and endurance, round bars are frequently employed in construction and engineering ventures. These bars function as weight-bearing elements in edifices, bridges, and other structures, offering essential support and stability. The availability of steel round bars in diverse grades and dimensions permits adaptability in both design and utilization. Moreover, they can be effortlessly welded, molded, and machined to fulfill precise project necessities, rendering them a favored option for structural applications.

- Q: What are the different international standards for steel round bars?

- Steel round bars have several international standards that define their specifications and requirements. Some commonly used standards are as follows: 1. ASTM A36/A36M: This standard focuses on carbon structural steel shapes, plates, and bars of structural quality. It is used in the construction of bridges and buildings through riveting, bolting, or welding. It specifies the chemical composition, mechanical properties, and dimensional tolerances for steel round bars. 2. ASTM A615/A615M: This standard lays down the requirements for deformed and plain carbon-steel bars used for concrete reinforcement. It covers bars with diameters ranging from 6 to 60 mm and provides guidelines for chemical composition, mechanical properties, and bend tests. 3. BS 4449: This British Standard deals with steel bars used to reinforce concrete. It outlines the requirements for carbon steel bars in different grades, such as B500B and B500C. It specifies the tensile properties, chemical composition, and dimensional tolerances for these steel round bars. 4. DIN 17100: This German standard specifies general structural steels, including steel round bars. It provides guidelines for the chemical composition, mechanical properties, and technical delivery conditions for various grades of steel bars. 5. JIS G3101: This Japanese Industrial Standard covers general structure rolled steel used for various applications. It includes steel round bars and defines the chemical composition, mechanical properties, and dimensional tolerances for different grades of steel bars. 6. ISO 6935-2: This International Organization for Standardization standard specifies the requirements for hot-rolled steel bars used for concrete reinforcement. It provides guidelines for the chemical composition, mechanical properties, and dimensional tolerances of steel round bars used in construction. These examples represent only a few of the international standards available for steel round bars. To ensure compliance and quality of the steel round bars used, it is essential to consult the appropriate standard based on the specific application and requirements.

- Q: What are the advantages of using low-alloy steel round bars?

- There are several advantages of using low-alloy steel round bars, which make them a popular choice in various industries. Firstly, low-alloy steel round bars offer increased strength and durability compared to regular carbon steel. This makes them suitable for applications that require high strength and resistance to wear and tear. The addition of alloying elements such as manganese, chromium, and nickel enhances the hardness and toughness of the steel, making it highly reliable and long-lasting. Secondly, low-alloy steel round bars exhibit excellent weldability and machinability. The presence of alloying elements allows for better control over the grain structure of the steel, resulting in improved weldability. This means that low-alloy steel round bars can be easily welded and fabricated into complex shapes without compromising their structural integrity. Additionally, their machinability enables efficient processing and customization according to specific requirements. Furthermore, low-alloy steel round bars offer enhanced resistance to corrosion and atmospheric conditions. The alloying elements present in these bars form a protective oxide layer on the surface, preventing the steel from rusting and deteriorating over time. This makes them ideal for outdoor applications exposed to harsh environments, such as construction, marine, and oil and gas industries. Moreover, low-alloy steel round bars are cost-effective compared to higher-alloy or stainless steel alternatives. While providing similar strength and performance, low-alloy steel is generally more affordable, making it a viable option for projects with budget constraints. This cost-effectiveness, combined with their durability and versatility, makes low-alloy steel round bars a preferred choice for a wide range of applications. In conclusion, the advantages of using low-alloy steel round bars include increased strength and durability, excellent weldability and machinability, resistance to corrosion, and cost-effectiveness. These properties make low-alloy steel round bars a reliable and versatile material for various industries, contributing to their widespread use in numerous applications.

- Q: What is the maximum weight capacity of a steel round bar?

- The maximum weight a steel round bar can hold depends on several factors, including its diameter, length, grade, and type of steel. Steel round bars are available in various sizes and grades, each with its own load-bearing capacity. To determine the maximum weight a steel round bar can handle, you need to calculate its cross-sectional area using the formula: Area = π * (diameter/2)^2. Here, π represents a mathematical constant that is approximately equal to 3.14159. Once you have the cross-sectional area, you can estimate the weight of the bar by multiplying it with the density of the specific steel grade. The density of steel varies based on the grade, but as a general approximation, it is around 7850 kilograms per cubic meter (or 0.00785 grams per millimeter cubed). However, it's important to remember that weight capacity alone may not be the only factor to consider for the safe use of a steel round bar. Other factors like load distribution, applied forces, and the structural integrity of the bar are equally important to ensure safe operation. For accurate weight capacity information for a specific steel round bar, it is recommended to refer to the manufacturer's specifications or consult a qualified engineer or professional who can provide precise calculations based on the specific requirements and characteristics of the steel round bar in question.

- Q: Can steel round bars be used for making rebar?

- No, steel round bars cannot be used for making rebar. Rebar, or reinforcing bar, is specifically designed and manufactured with deformations or ribs on its surface to enhance the bond with concrete. These deformations provide better grip and prevent slippage between the rebar and concrete, thus improving the structural integrity of a reinforced concrete structure. On the other hand, steel round bars have a smooth surface and lack the necessary deformations, making them unsuitable for rebar applications. It is important to use rebar that meets the required standards and specifications to ensure the safety and durability of the concrete structure.

- Q: What is the difference between a turned and a ground steel round bar?

- A turned steel round bar is a cylindrical steel rod that has been machined using a lathe to achieve a smooth and precise finish. This process removes material from the surface of the bar, resulting in a dimensional accuracy and a polished appearance. On the other hand, a ground steel round bar is also a cylindrical steel rod, but it undergoes a different machining process called grinding. Grinding involves using an abrasive wheel or belt to remove material from the bar's surface, resulting in a more precise diameter and a smoother finish compared to turning. In summary, the main difference between turned and ground steel round bars lies in the machining process used. Turning removes material through a lathe, while grinding involves an abrasive process for a more accurate and polished result.

- Q: What are the advantages of using sulfur-alloy steel round bars?

- There are several advantages to using sulfur-alloy steel round bars. Firstly, sulfur-alloy steel round bars have improved machinability compared to other types of steel. The addition of sulfur to the alloy reduces the friction between the tool and the workpiece, resulting in smoother cutting and lower cutting forces. This makes it easier and more efficient to machine the steel, saving time and reducing costs. Secondly, sulfur-alloy steel round bars have enhanced chip-breaking properties. The sulfur content promotes the formation of small, brittle sulfide inclusions within the steel, which act as chip breakers during machining. These inclusions help to break the chips into smaller pieces, preventing them from tangling and causing issues such as built-up edges or poor surface finish. Another advantage of sulfur-alloy steel round bars is their improved surface finish. The sulfur content in the alloy helps to reduce the occurrence of built-up edges or burrs during machining. This results in a smoother and more precise surface finish, which is particularly important for applications where aesthetics or tight tolerances are required. Additionally, sulfur-alloy steel round bars offer good wear resistance. The sulfur content in the alloy forms hard sulfide inclusions, which help to improve the hardness and wear resistance of the steel. This makes it suitable for applications where the round bars will be subjected to abrasive wear, such as in the manufacturing of gears or bearings. Lastly, sulfur-alloy steel round bars are often more cost-effective compared to other high-performance alloys. The addition of sulfur is a relatively inexpensive process, making sulfur-alloy steel a more affordable option for many applications. This makes it an attractive choice for industries that require high-quality steel but are conscious of costs. Overall, the advantages of using sulfur-alloy steel round bars include improved machinability, enhanced chip-breaking properties, better surface finish, good wear resistance, and cost-effectiveness. These benefits make sulfur-alloy steel round bars a popular choice in various industries, including automotive, aerospace, and manufacturing.

- Q: How are steel round bars used in the manufacturing of agricultural machinery?

- Steel round bars are commonly used in the manufacturing of agricultural machinery as they provide strength, durability, and flexibility. These bars are often used to construct various components such as axles, shafts, and pins, which play a crucial role in supporting and transmitting power within the machinery. The high tensile strength of steel round bars allows them to handle heavy loads and withstand harsh operating conditions, ensuring the reliability and longevity of the agricultural equipment.

- Q: What are the standard sizes of steel round bars?

- The sizes of steel round bars can vary depending on the country and specific industry standards. Typically, these bars come in a wide range of diameters, starting from 6mm (0.24 inches) and going up to 400mm (15.75 inches) or even larger. For commercial purposes, commonly used sizes include 10mm (0.39 inches), 12mm (0.47 inches), 16mm (0.63 inches), 20mm (0.79 inches), 25mm (0.98 inches), and 32mm (1.26 inches). However, it's important to note that these sizes may differ in various regions and industries. Additionally, specialized applications may require unique dimensions. Therefore, it's always advisable to refer to the relevant industry standards or consult with suppliers to determine the specific standard sizes for steel round bars in a particular context.

Send your message to us

Carbon Structural Steel Square Bars SS400CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches