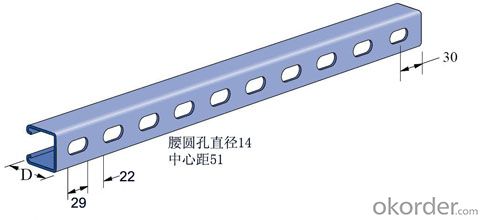

stress components -- type steel and fastener (with locking serrations)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The professional good coordination, improve indoor space elevation

Has good compatibility, the professional can share a hanger; make full use of space, can make each professional bundles can be good coordination.

- force, stable and reliable

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

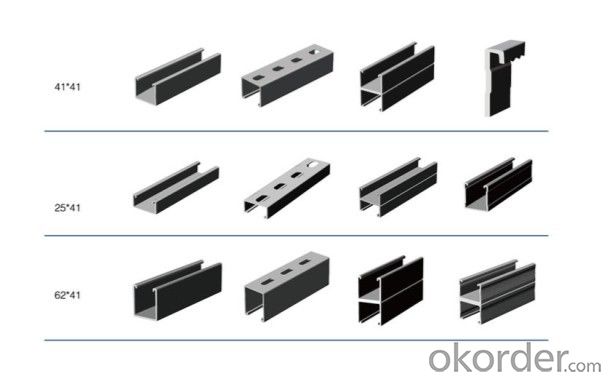

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

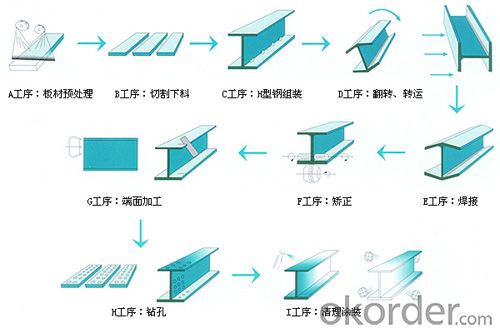

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room equipmentcontainer, mineral support etc.. The best-selling products, well received by customers. This is a company won the trust of customers, has broad prospects for development of theenterprise.

Z type steel main points: equilateral Z type steel, galvanized Z type steel, solar stent type Zsteel, the major and medium small type Z steel, Z shaped steel purlin, template supportoverlapped Z type steel Z steel, Z steel, such as automobile profiles, the above specifications for factory main products, such as shape, specifications, drawings can betransfer to my company.

- Q: What are the key considerations in the design of steel structures for industrial applications?

- Several key considerations must be taken into account when designing steel structures for industrial applications. First and foremost, the structural integrity of the steel structure is of utmost importance. Industrial environments typically involve heavy machinery, high loads, and potential impacts, necessitating a structure that can withstand these forces. The design should include thorough load calculations, taking into account not only static loads but also dynamic loads and potential vibrations. Secondly, the durability of the steel structure is a significant factor. Industrial environments can be harsh, with exposure to extreme temperatures, humidity, chemicals, and corrosion. Therefore, the choice of steel grade and protective coatings is critical to ensure the structure remains in optimal condition throughout its intended lifespan. Another crucial consideration is the functionality and layout of the industrial space. The design should account for the specific requirements of the industrial processes, including the arrangement of equipment and machinery, access points, and workflow efficiency. The structure should be flexible enough to accommodate potential future modifications or expansions. Safety is also of utmost importance in the design of steel structures for industrial applications. The design should adhere to all relevant safety standards and regulations, encompassing fire safety, escape routes, and emergency systems. Sufficient provision should be made for the installation of safety features such as handrails, guardrails, and safety barriers. Moreover, cost-effectiveness is an essential consideration. The design should aim to optimize material usage and minimize construction time and costs while still meeting the required performance and safety standards. Lastly, sustainability and environmental impact should be taken into consideration. By incorporating energy-efficient features, utilizing renewable energy sources, and utilizing recyclable materials, the design of steel structures can contribute to reducing the environmental footprint of industrial applications. In conclusion, the successful and efficient design of steel structures for industrial applications requires careful consideration of structural integrity, durability, functionality, safety, cost-effectiveness, and sustainability.

- Q: What is the role of steel canopies in a structure?

- Steel canopies play a crucial role in providing protection and enhancing the aesthetic appeal of a structure. They serve as a protective covering, shielding the building and its occupants from various weather elements such as rain, sun, and snow. Additionally, steel canopies can also act as architectural features, adding a visually pleasing element to the overall design of a structure.

- Q: What are the design considerations for steel structures in educational buildings?

- Some of the key design considerations for steel structures in educational buildings are strength and durability, flexibility, fire resistance, acoustics, and sustainability. Steel structures need to be strong and able to withstand various loads, such as the weight of the building and its contents, as well as potential seismic activity. Flexibility is important to accommodate the changing needs and future expansions of educational facilities. Additionally, steel structures should have good fire resistance to ensure the safety of occupants. Acoustic considerations are crucial to minimize noise transmission and create a conducive learning environment. Lastly, incorporating sustainable design practices, such as using recycled steel and energy-efficient materials, is important to minimize the environmental impact of educational buildings.

- Q: How do steel structures contribute to the overall natural light and ventilation of a building?

- Steel structures can contribute to the overall natural light and ventilation of a building by allowing for larger windows and open floor plans. The strength and flexibility of steel beams and columns allow architects to design buildings with more expansive glass facades, which in turn increase the amount of natural light entering the space. Additionally, steel structures can support larger openings for windows and doors, facilitating better air flow and ventilation throughout the building.

- Q: How are steel structures designed to accommodate fire suppression systems?

- Steel structures are designed to accommodate fire suppression systems by incorporating features that ensure the safety of the building and its occupants during a fire emergency. These design considerations include the provision of adequate space for the installation of fire suppression equipment, as well as the implementation of fire-resistant materials and fireproofing techniques. Firstly, steel structures are designed with sufficient space and access points to accommodate fire suppression systems. This includes the placement of fire hoses, extinguishers, and other firefighting equipment at strategic locations throughout the building. The design also incorporates the provision of fire hydrants and fire department connections to ensure easy access for firefighters. In addition to space considerations, steel structures employ fire-resistant materials and techniques to enhance fire safety. The use of fire-rated walls and partitions helps to compartmentalize the building, preventing the rapid spread of fire and smoke. These fire-rated barriers are designed to withstand high temperatures and provide a safe escape route for occupants. Furthermore, steel structures may incorporate fireproofing techniques to protect the structural integrity of the building during a fire event. Fireproofing materials, such as intumescent coatings or fire-resistant insulation, are applied to the steel elements to delay their exposure to high temperatures. This allows the steel to retain its load-bearing capacity for a longer period, giving occupants more time to evacuate and firefighters more time to control the fire. Moreover, fire suppression systems in steel structures are often integrated with the building's overall fire safety strategy, which includes fire alarms, smoke detectors, and automatic sprinkler systems. These systems work together to detect and suppress fires at the earliest possible stage, minimizing the risk of extensive damage and ensuring the safety of occupants. In conclusion, steel structures are designed to accommodate fire suppression systems by providing adequate space for firefighting equipment, incorporating fire-resistant materials and techniques, and integrating fire suppression systems with the building's overall fire safety strategy. These design considerations help to ensure the safety of the building and its occupants during a fire emergency.

- Q: What are the different types of steel balconies and terraces used in buildings?

- There are several types of steel balconies and terraces commonly used in buildings, including cantilevered balconies, Juliet balconies, wrap-around balconies, and rooftop terraces. Cantilevered balconies are supported by beams or brackets that extend from the building, giving the illusion of floating. Juliet balconies are small, decorative balconies that are usually placed outside windows and are not intended for full use. Wrap-around balconies extend along multiple sides of a building, providing panoramic views. Rooftop terraces are open spaces on the top of a building that can be used as outdoor living areas.

- Q: How are steel structures used in solar and renewable energy projects?

- Steel structures are widely used in solar and renewable energy projects due to their numerous advantages and suitability for such applications. In solar projects, steel is primarily used for the construction of mounting systems, which are essential for securing solar panels in place. These mounting systems can be fixed or tracking, depending on the specific requirements of the project. Steel structures provide the necessary structural integrity and stability to withstand various environmental conditions, including wind, snow, and seismic loads. They offer a high strength-to-weight ratio, enabling the installation of large solar arrays without compromising stability. Moreover, steel is a durable material that can withstand corrosion, making it a reliable option for long-term outdoor use. Steel structures can also be easily fabricated and customized to suit the specific needs of solar projects. They can be designed to accommodate different panel sizes and configurations, allowing for efficient utilization of space. Furthermore, steel structures can be easily assembled and disassembled, making them suitable for both permanent and temporary installations. In renewable energy projects, steel structures are not limited to solar applications. They are also widely used in wind farms to support wind turbines. Steel towers are used to elevate wind turbines to optimal heights for capturing maximum wind energy. These towers are designed to withstand the dynamic loads and vibrations associated with wind turbines, ensuring their stability and reliability. Additionally, steel structures are utilized in other renewable energy projects, such as biomass power plants and hydropower facilities. In biomass power plants, steel is used for the construction of boilers and storage tanks, which are essential components of the energy generation process. In hydropower facilities, steel is used for penstocks, gates, and other structures that facilitate the flow and control of water to generate electricity. Overall, steel structures play a crucial role in solar and renewable energy projects by providing the necessary support, durability, and flexibility required for these applications. Their strength, versatility, and cost-effectiveness make them the material of choice for constructing the infrastructure needed to harness and utilize clean and sustainable energy sources.

- Q: How are steel structures designed and constructed to meet specific architectural requirements?

- Steel structures are designed and constructed to meet specific architectural requirements through a comprehensive and meticulous process. Firstly, the architectural requirements are thoroughly analyzed, including factors such as the purpose of the structure, the desired aesthetics, and the functional needs of the building. Once these requirements are clearly defined, the design phase begins. During the design phase, engineers and architects collaborate to create a structural design that fulfills the architectural requirements. This includes determining the load-bearing capacities, the size and placement of columns and beams, and the overall layout of the structure. Advanced computer-aided design (CAD) software is often used to create 3D models and simulations that help visualize and refine the design. Steel, being a highly versatile and durable material, is often the preferred choice for structural elements in architectural designs. It offers excellent strength-to-weight ratio, allowing for the creation of large and open spaces with minimal obstructions. The steel members are carefully selected based on their properties and then incorporated into the design. Once the design is finalized, the construction process begins. The steel structure is fabricated off-site in specialized factories, where the steel members are manufactured according to the design specifications. This ensures precision and quality control. The fabricated parts are then transported to the construction site for assembly. During the construction phase, the steel members are erected and connected using various techniques such as welding or bolting. Skilled labor, including ironworkers and welders, play a crucial role in ensuring the accurate and safe construction of the steel structure. The construction process also includes the installation of other components like flooring, roofing, and cladding, which are integrated with the steel structure. To meet specific architectural requirements, additional architectural elements may be incorporated into the steel structure. These can include features like curved or cantilevered sections, unique facade systems, or specialized finishes. These elements are carefully integrated into the design and construction process to ensure they are structurally sound and aesthetically pleasing. Throughout the entire design and construction process, compliance with relevant building codes and regulations is essential. Structural engineers ensure that the steel structure meets all safety standards and can withstand the expected loads and environmental conditions. Additionally, regular inspections and quality control measures are implemented to ensure the durability and longevity of the steel structure. In conclusion, steel structures are designed and constructed to meet specific architectural requirements through a meticulous process that involves careful analysis, precise design, and skilled construction. By utilizing the versatility and strength of steel, architects can create innovative and functional structures that meet the desired aesthetic and functional goals.

- Q: What are the considerations for designing steel structures in areas with high snow accumulation?

- When it comes to designing steel structures in areas where there is a high amount of snow, there are several important factors that need to be taken into account. 1. Snow Load: The primary concern is the amount of snow that the structure will have to bear. Snow is heavy and can put a significant amount of pressure on the roof and other parts of the building. The designer must determine the snow load based on local climate data and regulations. 2. Structural Integrity: Steel structures must be able to withstand the additional weight of the snow. This requires a careful analysis of the structural members, connections, and overall design to make sure that they can support the snow load without compromising the integrity of the structure. 3. Roof Design: The design of the roof is crucial in areas with high snow accumulation. It is often preferred to have a sloped or pitched roof as this allows the snow to slide off more easily, reducing the load on the structure. The angle of the roof and the use of snow guards or other devices to prevent large amounts of snow from sliding off should be considered. 4. Drifts and Sliding: Snow can accumulate in drifts or slide down from higher areas, putting concentrated loads on certain parts of the structure. Proper design should take these factors into account and distribute the snow load evenly to avoid putting too much stress on one area. 5. Thermal Effects: Snow accumulation can insulate the roof, reducing heat transfer and potentially causing the structure to expand or experience stress. The design should consider these effects to make sure that the steel members can handle these changes without failing. 6. Building Codes and Regulations: It is essential to comply with local building codes and regulations when designing steel structures in areas with high snow accumulation. These codes provide guidelines for calculating snow loads, designing structural members, and ensuring the safety and stability of the building. 7. Maintenance and Snow Removal: Designing steel structures in areas with high snow accumulation also requires considering access for snow removal and maintenance. Features such as roof access points, adequate drainage systems, and provisions for snow removal equipment should be included in the design. In conclusion, designing steel structures in areas with high snow accumulation involves careful consideration of snow load, structural integrity, roof design, drifts and sliding, thermal effects, compliance with building codes, and maintenance requirements. By addressing these considerations, engineers can ensure that steel structures in snowy regions are safe, durable, and functional.

- Q: What are the different types of steel balconies and terraces used in buildings?

- There are several different types of steel balconies and terraces used in buildings, each with its own unique characteristics and advantages. 1. Cantilevered balconies: These balconies are supported by projecting beams or brackets that are fixed to the building structure. Cantilevered balconies provide an open and unobstructed view, as there are no supporting columns or posts. 2. Suspended balconies: Suspended balconies are attached to the building using cables or rods, giving them a floating appearance. These balconies are often seen in modern architecture and provide a sleek and contemporary look. 3. Juliet balconies: Juliet balconies are shallow balconies that are typically installed on the upper floors of buildings. They feature a protective railing or balustrade and are designed to provide a decorative element rather than a functional outdoor space. 4. Terrace gardens: Terrace gardens are larger outdoor spaces that are built on rooftops or elevated areas of a building. These terraces often have a steel structure as a base, providing stability and support for the garden above. 5. Steel railings and balustrades: In addition to balconies and terraces, steel is commonly used for railings and balustrades. These elements provide safety and aesthetic appeal, and can be customized to suit the design of the building. When selecting a steel balcony or terrace for a building, factors such as structural requirements, aesthetic preferences, and budget should be considered. It is important to consult with architects, engineers, and construction professionals to determine the most suitable type of steel balcony or terrace for a specific project.

Send your message to us

stress components -- type steel and fastener (with locking serrations)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords