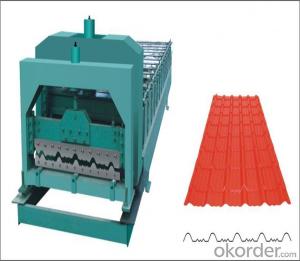

Steel Tile Roll Forming Machine in Good Shape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL TILE ROLL FORMING MACHINE

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2. Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3. What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4.Is the machine automatic?

Yes, it can be manual and automatic.

- Q: How is the surface finish of the final product improved in metal casting machinery?

- The surface finish of the final product is improved in metal casting machinery through various methods such as using high-quality molds, employing precise and controlled casting processes, implementing advanced cooling techniques, and employing post-casting treatments like grinding, polishing, or coating. These measures help eliminate defects, enhance the overall surface smoothness, and achieve the desired surface finish for the final product.

- Q: How are molds designed and operated for continuous casting in metal casting machinery?

- Molds used for continuous casting in metal casting machinery are designed and operated in a way that ensures the efficient and continuous production of metal products. The design and operation of these molds play a crucial role in maintaining the quality and consistency of the cast metal. To begin with, the mold design takes into consideration various factors such as the type of metal being cast, its chemical composition, and the desired shape and dimensions of the final product. The mold is typically made of refractory materials that can withstand high temperatures and the corrosive nature of molten metal. It is designed to have a specific shape and size that allows for the smooth and controlled flow of the molten metal. Mold operation involves several steps to ensure the continuous casting process. Firstly, the mold is preheated to a temperature suitable for the specific metal being cast. This ensures that the molten metal does not solidify before it reaches the mold. Additionally, the mold is coated with a refractory material or a lubricant to facilitate the easy release of the solidified metal. Once the mold is prepared, the metal is continuously poured into it through a controlled pouring system. The design of the pouring system ensures a steady flow of molten metal into the mold, preventing any interruptions or inconsistencies. The mold is equipped with cooling systems, such as water or air cooling, to solidify the molten metal at a controlled rate. This allows for the formation of a solidified shell on the outside of the metal, while the inside remains liquid. As the metal solidifies, it is continuously extracted from the mold at a controlled speed. This is achieved through the use of withdrawal systems, which may involve rollers, belts, or other mechanisms. The mold is designed to allow for the smooth extraction of the solidified metal without causing any damage or deformations. Throughout the continuous casting process, monitoring and control systems are in place to ensure the quality of the cast metal. These systems monitor parameters such as temperature, flow rate, and the dimensions of the cast product. Any deviations from the desired specifications can be quickly identified and adjusted to maintain the quality and consistency of the cast metal. In summary, molds used in continuous casting in metal casting machinery are designed and operated with careful consideration of the metal being cast and the desired product. The design ensures a smooth flow of molten metal, controlled solidification, and easy extraction of the solidified metal. Proper operation, along with monitoring and control systems, ensures the production of high-quality and consistent metal products.

- Q: Can metal casting machinery be used for investment casting of fiber-reinforced polymers?

- No, metal casting machinery cannot be used for investment casting of fiber-reinforced polymers. Investment casting is a process primarily used for casting metals, where a wax pattern is coated with a ceramic shell, melted out, and then filled with molten metal. Fiber-reinforced polymers involve the use of composite materials, typically consisting of a polymer matrix reinforced with fibers. The manufacturing process for fiber-reinforced polymers is different and requires specialized equipment, such as fiber placement machines or filament winding machines, to accurately lay down the fibers and impregnate them with the polymer matrix.

- Q: How are cores positioned and supported in metal casting machinery?

- In metal casting machinery, cores are positioned and supported using various techniques to ensure stability and accuracy during the casting process. Cores are typically made of sand or other materials and are used to create cavities or complex shapes within the final casting. One common method of positioning cores is by using core prints or core seats. These are recessed areas or projections on the mold or pattern that help to locate and support the cores. The core prints provide a precise fit for the cores and ensure they are securely held in place during the pouring of molten metal. In addition to core prints, cores can also be supported using core pins or dowels. These are cylindrical rods that are inserted into the core and then into the mold or pattern. The core pins provide additional support and prevent the core from shifting or moving during the casting process. Another technique used to support cores is the use of chaplets or chaplet wires. Chaplets are small metal supports that are placed between the core and the mold to hold the core in position. They are typically made of a material that will melt or disintegrate during the casting process, allowing the core to be removed easily after solidification. Furthermore, supports such as core rods, cores plates, or core boxes can be used to stabilize and position large or complex cores. These supports ensure the cores maintain their shape and position throughout the casting process. Overall, the positioning and support of cores in metal casting machinery are critical to ensure the integrity and quality of the final castings. By using a combination of techniques such as core prints, core pins, chaplets, and supports, manufacturers can achieve accurate and precise casting results.

- Q: How is the molten metal poured into the mold in metal casting machinery?

- In metal casting machinery, the molten metal is poured into the mold using a process called casting. The first step is to prepare the mold by creating a cavity in the desired shape of the final product. This can be done by using a pre-made mold or by creating a mold from sand, ceramic, or other materials. Once the mold is prepared, it is securely clamped or fastened to the casting machine. The molten metal, which is usually heated in a furnace to reach its liquid state, is then poured into a ladle or crucible. The ladle or crucible is designed to hold and transport the molten metal safely. The molten metal is carefully poured from the ladle or crucible into the mold. This can be done manually by an operator or automatically through a robotic system, depending on the complexity and size of the casting machine. It is important to pour the molten metal slowly and evenly to avoid any turbulence or air entrapment that may result in defects in the final casting. After the molten metal is poured into the mold, it is left to cool and solidify. The cooling time may vary depending on the type of metal and the size of the casting. Once the metal has solidified, the mold is opened or removed, revealing the newly formed metal casting. Overall, the process of pouring molten metal into the mold in metal casting machinery requires precision, control, and attention to detail to ensure the final product meets the desired specifications and quality standards.

- Q: What is the maximum size of castings that can be produced using metal casting machinery?

- The maximum size of castings that can be produced using metal casting machinery varies depending on the specific machinery and capabilities. However, in general, metal casting machinery can produce castings ranging from small, intricate components to large, heavy parts weighing several tons.

- Q: How does metal casting machinery handle the testing and inspection of castings?

- Metal casting machinery handles the testing and inspection of castings through various methods. One common approach is non-destructive testing, where techniques like X-ray, ultrasonic testing, and magnetic particle inspection are used to detect any flaws or defects in the castings. Additionally, dimensional inspection tools such as coordinate measuring machines and optical inspection systems are employed to ensure accuracy and adherence to specifications. These testing and inspection processes are crucial in maintaining the quality and integrity of castings produced by the machinery.

- Q: How does metal casting machinery handle the removal of excess material from centrifugal castings?

- Metal casting machinery typically handles the removal of excess material from centrifugal castings through a process known as centrifugal cleaning. Once the casting has solidified, it is removed from the mold and placed in a centrifuge chamber. The chamber is then spun at high speeds, causing the excess material, such as gates, risers, and flash, to be forced outwards due to centrifugal force. This excess material is then collected and separated from the casting, leaving behind a clean and finished product.

- Q: What are the different types of quality control measures used in metal casting machinery?

- There are several types of quality control measures used in metal casting machinery, including visual inspection, dimensional measurement, non-destructive testing, and material analysis. Visual inspection involves visually examining the casting for any defects, such as cracks, porosity, or surface irregularities. Dimensional measurement ensures that the casting meets the required specifications and tolerances. Non-destructive testing techniques, such as ultrasonic testing or X-ray inspection, are used to detect internal defects that may not be visible to the naked eye. Material analysis involves testing the composition and properties of the metal being cast to ensure it meets the desired standards. These quality control measures help ensure the integrity and quality of the castings produced by the machinery.

- Q: How does metal casting machinery handle the extraction of castings from the molds?

- Metal casting machinery handles the extraction of castings from the molds through a process known as shakeout. Shakeout involves mechanically vibrating or shaking the mold to release the casting from the sand mold. There are different methods and types of machines used for this process. One common method is using a vibratory shakeout machine. This machine consists of a large vibrating table or conveyor belt that moves the mold back and forth, causing the sand to break away from the casting. The vibrations help to loosen the sand particles and allow the castings to separate. Another method is using a knockout machine, which utilizes pneumatic or mechanical force to remove the casting from the mold. This machine typically has a ram or a plunger that applies pressure to the mold, forcing the casting out. In some cases, molds may be designed with collapsible sections or sand cores that can be easily removed, allowing the castings to be extracted more easily. This is often used for complex or intricate castings that require additional flexibility during the extraction process. Overall, metal casting machinery is designed to efficiently and effectively handle the extraction of castings from the molds. These machines are specifically engineered to minimize damage to the casting while ensuring the sand is effectively removed, resulting in high-quality castings.

Send your message to us

Steel Tile Roll Forming Machine in Good Shape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches