Steel Tile Roll Forming Machine with CE&ISO

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

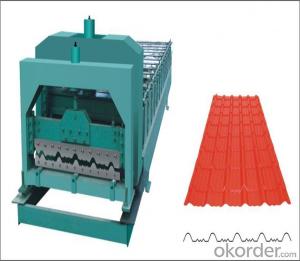

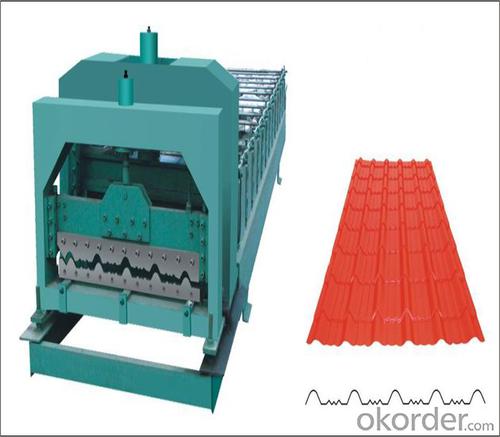

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: Where can a concrete mixer be used?

- A concrete mixer is a machine that mixes cement, gravel and water into concrete mixtures. It consists mainly of mixing, loading and unloading mechanism, water supply system, original motive, transmission mechanism, frame and supporting device. Concrete mixer, including through the shaft connected to the transmission mechanism of driving and driven by the actuator cylinder, the cylinder cylinder jacket around the cylinder cylinder gear ring set, set with the ring gear meshing gear on the shaft. The utility model has simple structure, reasonable, the use of mesh gear, gear ring, which can effectively overcome the fog had, between the roller and the mixer drum skid phenomenon; The driving mechanism can further assure the skidding between the roller and the mixer. Are suitable for all kinds of medium and small precast file and water conservancy, Bridges, roads, ports, docks, industrial and civil building engineering stirring harsh concrete, plastic concrete, active concrete and lightweight aggregate concrete and mortar

- Q: What are the pros and cons of a concrete mixer?

- Are you talking about the production line at the blender station or is it the usual blender or that? These I understand

- Q: How long will it take for a concrete mixer to beat ten square?

- 1, 2 square, each time you can mix 1 square, top material, stirring, material for about 10 minutes, (depending on the material speed), 10 square about 100 minutes

- Q: How many tiles are in the concrete mixer on the site

- 7500L concrete mixer, 7.5kw, and 3.5kw, total power of about 12KW

- Q: How to safely use concrete mixer

- Concrete mixer operation method: 1. The concrete mixer should be placed in a firm place, with the support of the bracket or the support of the foot barrel, and cannot be supported by the tyre. Before the concrete mixer starts, check whether the controller is good. When the concrete mixer is hoisted in the hopper, it is strictly forbidden to pass or stop by the hopper and set up the mixer after the work is completed. When the concrete mixer is running, it is strictly forbidden to put the tools in the roller, and pay more attention to safety. When the concrete mixer is on site, it should be fixed in the mixer, cut off the power supply, and when it enters the mixer cylinder, the outside must be monitored. (the operator of the concrete mixer (driver) must be trained in safety technical training, qualified for examination, and will be held on the certificate and strictly prohibit non-driver operation. The concrete mixer must clean the inside, especially in the winter, which can prolong the service life by using no foreign material in the front roller.

- Q: How the concrete mixer works

- The concrete mixer can be divided into two categories: self-fall and strong. Self-falling concrete mixer is suitable for mixing plastic concrete. The stirring effect of a strong mixer is stronger than that of the falling mixer, which is suitable for mixing hard concrete and lightweight aggregate concrete. A concrete mixer is a machine that stirs a certain mix of sand, stone, cement and water into a uniform quality concrete that meets the quality requirements. The concrete mixer can be divided into two categories: self-fall and strong.

- Q: How much is the blender machine stirring

- The incoming material is 450 litres and can be used for 350 litres at a time

- Q: How does a concrete mixer operate

- If the machine is relatively new, the button will have, it's going to go up, go down, automatically add water, add water by hand, mix it up, mix it up, stop, vibrate

- Q: 250 litres of the blender once made concrete

- A concrete is a cubic meters, 250 litres of mixer can only every time out two-thirds of that which is around 170 litres, more easy to stir or uneven, wear a blender.

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- The jw-200 type mixer consists mainly of the main parts, such as the platform car, the motor, the gearbox, the feeding mechanism, the mixing mechanism and the feeding trough. After the electric start-up, the process of feeding, stirring and discharging is carried out through the transmission such as the triangle belt, the coupler and the worm gear reducer. The concrete mixer is small and suitable for underground.

Send your message to us

Steel Tile Roll Forming Machine with CE&ISO

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords