High Pressure Continuous PU Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of High Pressure Continuous PU Sandwich Panel Production Line

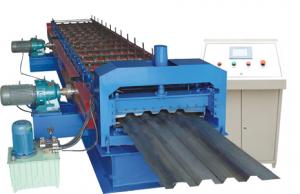

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint design.

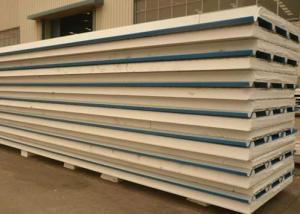

Sandwich panel, as a new building material show excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Continuous sandwich panel line is mainly composed of laminator, forming machine, cutting unit. With the simultaneously polyurethane foaming, this production line is able to realize the continuous sandwich panel production, length to cut by PLC control, speed control by inverter, and polyurethane panel solidifying process is completed in the double-chain laminator. This production line, with the high production rate and automation, accurate synchronization, is extremely appropriate for polyurethane sandiwch panel prodcution in a large scale, which is prior in constructing high quality large-size buildings.

Specifications of High Pressure Continuous PU Sandwich Panel Production Line

Reuqire specifications of raw materials:

Thickness of panel: 0.37-1.2mm

Track width (max): 1250mm

Weight of uncoil (max): 5 tons

Inner dia: 500-600mm

Dimension of the sandwich panel available to produce

Length: 2-20m

Width: 900-1100mm

Panel thickness (min): 30mm

Panel thickness (max): 200mm

Production/Operation rate: 3-10m/min

Length of the whole production line: about 120m

Useful length of the double track: 25m

Working height: 1200mm

The pressure of pour foaming: 150-200 bar

Complete line consist of:Uncoiler (auto), Forming machine, Steel/Panel heating machine, Heating frame (move auto), Foaming machine, Main engine with double track, Heating machine with double track, Band saw cutter, Automatic stacker and Auto electric controller

Applications of High Pressure Continuous PU Sandwich Panel Production Line

This metal forming machine is indispensable equipment for producing the wall panel and roof panel for industrial workshops, warehouses etc.

Technical Data of High Pressure Continuous PU Sandwich Panel Production Line

1. The Manufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjust speed)

2. The Thickness Of Sandwich Panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of The Production Line : about 120 meters

5. The Total Power Of The Production Line : 350 KW

6. The Length Of The Double Belt Conveyer : 24m

Packaging & Delivery of High Pressure Continuous PU Sandwich Panel Production Line

1. Main machine is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.

3. Delivery:80 days.

- Q: How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- New composite plate is a new type of building materials developed rapidly in five to ten years, because these new building materials can meet the technical indicators of building structure, insulation and other related aspects, and has the advantages of low cost, light weight, convenient construction investment Sheng, reusable characteristics, has been strongly recommended by the administrative Department of construction.

- Q: How to thread the EPS (color steel) sandwich panel?

- EPS plate can not use the dark cable way, must use PVC flame retardant pipe line, need to use the hole opening device, open out also good-looking.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: How is the sandwich plate synthesized?

- The sandwich panel is made up of two layers of metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q: What is the color steel sandwich board?

- The intermediate sandwich panel is two color steel with polyurethane foam with a layer of insulating material.

- Q: Can the sandwich board adhere to the plaster line?

- Carpentry board is big core board, it is solid wood to spell, gesso board is gesso to make, outside a layer of kraft paper, two material is different. Wood board is commonly used materials currently Jiezhuang, generally used as lining making furniture, door, use is very extensive. Gypsum board is generally used for ceiling, television, wall and so on, but it needs carpentry rendering.

- Q: Rock wool, color steel sandwich plate production line where good?

- The rockwool sandwich panel production line has a strip of 250mm thick high density rock wool board cutting, automatic transmission, 90 degree flip and saw sandwich plate after forming cutting, automatic stacking, wrapping, can produce different types of wall panels, roof panel, door panel and cold plate etc..

- Q: What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- The upper and lower track plates of the fixed polyurethane plate are not smooth, mainly because of the processing problem, the chain drive polygon effect or the equipment level is not adjusted properly;

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- Foam sandwich board, beautiful shape, bright color, good overall effect, it sets the bearing, thermal insulation, waterproof in one, and no two decoration, is a widely used, especially in the temporary facilities for construction sites such as office, warehouse, wall and so on, but also the modern construction site civilization construction.

- Q: What does color steel sandwich board mean?

- The color steel sandwich panel product is composed of two layers of formed metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 23.41% Eastern Europe 20.29% Southeast Asia 16.91% Mid East 11.68% Africa 11.00% South America 8.74% North America 4.30% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

High Pressure Continuous PU Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches