Half-Speed Steel Roll With High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM Group is integrated with four business segments: Manufacture, R&D,Sets of equipment and Logistics trading.Mill rolls are our main products.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 120 countries and regions all over the world.

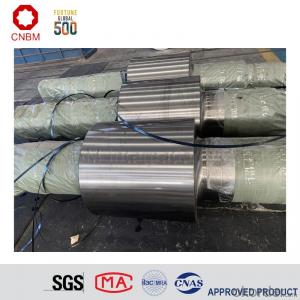

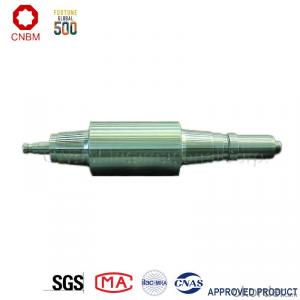

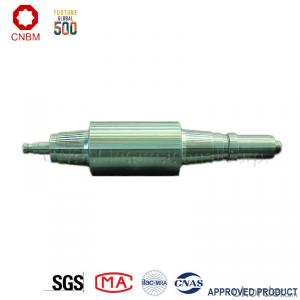

The product introduction of mill roll

Equipped with advanced technological facilities on melting, casting, forging, heat treating and mechanical machining, our factory has formed 9 professional complete roll manufacturing lines of cast steel, cast iron and forged steel rolls such as strip mill rolls, heavy section mill rolls, wire & bar rolls, special shaped rolls and small-sized cold rolls and specialized production lines of bloom and slab CCM, coke oven equipments and wind power products. Annual production capacity of mill rolls is 500,000 tons, metallurgical equipment is 80,000 tons.

Workshop

Workshop is the core of our company and undertakes all of scientific research work. The company specially produces and supplies all kinds of roll used for hot strip mill, cold strip mill, plate & heavy plate mill, large-sized section mill, universal mill etc.

Products & Specification

| Mill | Application | Material | Product Specification | ||

| Hot Strip Mill | Large-sized vertical roll | Special alloy cast roll, Adamite | All Sizes | ||

| Small-sized vertical roll | Adamite, HiCr iron | ||||

| Roughing work roll | Special alloy cast steel, Adamite, HiCr steel, Semi-HSS, HiCr iron | ||||

| Finish rolling | Early stand work roll | HiCr iron, HSS | |||

| Later stand work roll | ICDP, HSS | ||||

| Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |||

| Alloy forged steel | D≤¢2000,W≤75t | ||||

| Temper rolling | Work roll | HiCr iron | All Sizes | ||

| Alloy forged steel | |||||

| Back-up roll | ICDP | ||||

| Duplex cast steel | D≤¢2000, W≤80t | ||||

| Alloy forged steel | D≤¢2000, W≤75t | ||||

| Mill | Application | Material | Product specification |

Cold strip mill & Single stand cold mill | Work roll | Alloy forged steel | All Sizes |

| Intermediate roll | Alloy forged steel | ||

| Temper roll | Alloy forged steel | ||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |

| Alloy forged steel | D≤¢2000,W≤75t | ||

Largesized universal structural mill | Break-down roll | Special alloy cast steel, alloy nodular iron | All Sizes |

| Horizontal collar | High carbon adamite (duplex) | ||

| Vertical collar | High carbon adamite, HiCr iron | ||

| Edger roll Edger roll | High carbon adamite | ||

| Shaft | Alloy forged steel |

| Mill | Application | Marterial | Product Specification | |

| CSP | Vertical Roll | Adamite, Special alloy cast steel, HiCr iron | All Sizes | |

| Roughing work roll | Semi-HSS, HiCr Steel | |||

| Finish rolling | Early stand | HiCr iron, HSS | ||

| Later stand | ICDP, HSS | |||

| Roughing & Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Steckel Mill | Vertical roll | Adamite, Special alloy cast steel | All Sizes | |

| Roughing work roll | ICDP, HiCr iron | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Plate & Heavy plate mill | Rough rolling | 2-hi work roll | Special alloy cast steel, Tool steel | All Sizes |

| 4-hi work roll | HiCr iron, ICDP | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Single stand work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

Quality Control

The company has the most advanced experimental and testing equipments in global mill roll industry, including direct-reading spectrometer, spectrum analyzer , X-ray fluorescence analyzer, scanning electronic microscope, energy disperse spectroscopy, X-ray diffractometer, image analyzer, high/low temperature metallographic microscope, X-ray stress meter, brittleness temperature tester, thermal analogue machine, dilatometer, macro and micro hardness tester, OMNISCAM-1X automatic flaw detection, USN60 ultrasonic flaw detector, magnetic powder and non-destructive flaw detection etc,. The advanced inspection equipments and experimental methods provide guarantee for quality control and experiment on material, usability test and performance.

The factories of CNBM invested 2.3 billion RMB for large-scale

CNBM international Corporation has completed equipment and technology upgrade transformation, which was concentrated on three projects, production line of centrifugal casting rolls for hot strip and plate mill, forged roll for cold/hot strip mill, national class technology center and roll material lab. Through upgrade transformation, the following targets have been achideved:

(1)It becomes the world's biggest specialized mill roll maker with the largest production scale, the most complete specifications of products and the most extensive coverage of various rolls used on rolling mill.

(2) The technology of equipments has reached international leading level.

(3) "Mechanization, automation, intellectualization, digitization" of equipments obviously improve the quality control ability.

(4) New types of research instruments improve the R&D capacity of products.

Customers Visit

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: How is the casting tested for mechanical properties in metal casting machinery?

- Ensuring the quality and reliability of the final product in metal casting machinery involves a critical step of conducting casting testing for mechanical properties. Various methods are utilized to test the mechanical properties of castings, including: 1. Tensile Testing: In this test, the casting's tensile strength is evaluated by subjecting it to a controlled pulling force. A sample is prepared from the casting and loaded into a machine specifically designed for tensile testing. The amount of force required to fracture the sample is recorded, providing valuable information about the casting's strength and ductility. 2. Hardness Testing: This test measures the hardness of the casting, which serves as an important indicator of its resistance to wear and deformation. Different methods such as Brinell, Rockwell, or Vickers hardness testing can be employed based on the casting material and specific requirements. 3. Impact Testing: This test assesses the casting's capability to withstand sudden loading or impact forces. A standardized impact test machine is used to strike a notched sample, and the energy absorbed during fracture is measured. This test helps determine the casting's toughness and resistance to brittle failure. 4. Compression Testing: The resistance of a casting to crushing forces is measured through compression testing. The casting sample is compressed between two plates, and the force required to deform or fracture the sample is recorded. This test provides significant data about the casting's compressive strength and stability. 5. Ultrasonic Testing: Ultrasonic testing employs high-frequency sound waves to detect internal defects such as voids, cracks, or inclusions in the casting. Trained operators analyze the echoes generated by the sound waves to identify potential issues that may impact the casting's mechanical properties. 6. Radiographic Testing: This method involves using X-rays or gamma rays to examine the internal structure of the casting. Radiographic images reveal defects that may not be easily detectable through visual inspection, such as shrinkage, porosity, or inclusions. By analyzing these images, casting engineers can assess the casting's integrity and mechanical properties. These testing methods, along with others, are utilized to ensure that the metal casting machinery produces castings with the desired mechanical properties. To guarantee the reliability and safety of the final products, it is crucial to adhere to rigorous testing protocols and standards.

- Q: What are the different types of risers used with metal casting machinery?

- There are several types of risers used with metal casting machinery, including top risers, side risers, and blind risers. Top risers are positioned on top of the casting mold and allow for the escape of gases and impurities during the solidification process. Side risers are located on the sides of the mold and serve a similar purpose, aiding in the removal of gases and ensuring a more uniform solidification. Blind risers, on the other hand, are not connected to the casting and are used solely to provide additional molten metal to compensate for shrinkage during solidification.

- Q: Can metal casting machinery be used for investment casting of concrete?

- Metal casting machinery is not suitable for investment casting of concrete. The machinery is exclusively designed for casting molten metal into different shapes and forms. On the other hand, investment casting of concrete involves a distinct process and requires specific equipment. Generally, this process entails creating a mold or formwork, pouring wet concrete into the mold, allowing it to cure and dry, and eventually removing the mold to unveil the final concrete shape. Specialized equipment and techniques are essential for this process, which differ from those used in metal casting machinery.

- Q: How does metal casting machinery handle the removal of metal from molds?

- Metal casting machinery uses various methods to handle the removal of metal from molds. One common technique is known as shakeout, where the mold is vibrated or shaken to release the cast metal. This process helps separate the metal from the mold material, such as sand or ceramic, which is then discarded or recycled. Another method is knockout, which involves using mechanical force to remove the cast metal from the mold. This can be done manually or with the help of pneumatic or hydraulic systems that exert pressure to dislodge the metal. Additionally, some metal casting machinery employs the use of mold release agents to facilitate the removal process. These agents are applied to the mold surface before casting, forming a thin film that reduces the adhesion between the metal and the mold. As a result, the metal can be easily removed from the mold without causing any damage. Furthermore, in certain advanced metal casting techniques like investment casting, the molds are made of a material that can be easily broken or dissolved. Once the metal has solidified, the mold is shattered or dissolved, allowing the metal casting to be easily retrieved. Overall, metal casting machinery utilizes a combination of mechanical force, vibration, mold release agents, and specialized mold materials to handle the removal of metal from molds efficiently and safely.

- Q: How can casting defects be identified and corrected in metal casting machinery?

- Casting defects in metal casting machinery can be identified and corrected through various methods. Here are some ways to address and rectify these issues: 1. Visual Inspection: Conduct a visual examination of the castings to identify any visible defects such as cracks, surface irregularities, or porosity. Defective castings can be segregated and corrective measures can be implemented accordingly. 2. Non-Destructive Testing (NDT): Utilize NDT techniques like X-ray, ultrasonic testing, magnetic particle inspection, or dye penetrant inspection to detect internal defects that may not be visible to the naked eye. NDT helps in identifying issues such as voids, inclusions, or improper filling of the mold. 3. Process Monitoring: Regularly monitor the casting process parameters such as temperature, pressure, and flow rate. Deviations from the desired conditions can lead to defects. By closely monitoring these parameters, any variations can be identified and corrected promptly. 4. Mold Design and Preparation: Ensure that the mold design is appropriate for the casting process. Any issues with the mold, such as poor venting, improper gating, or mismatched cores, can result in defects. Proper mold preparation techniques like cleaning, coating, and preheating can also help prevent defects. 5. Material Quality Control: Conduct stringent quality checks on the raw materials used in the casting process. Ensure that the metal alloy composition, purity, and grain size meet the required specifications. Poor quality materials can lead to defects like shrinkage, hot tearing, or metallurgical issues. 6. Process Optimization: Analyze the casting process parameters and optimize them for better quality and productivity. This may involve adjusting pouring temperature, altering cooling rates, modifying pouring techniques, or implementing better gating systems. Process optimization helps minimize defects and improve overall casting quality. 7. Training and Skill Development: Provide proper training to the personnel involved in the casting process. This includes operators, mold makers, and quality control inspectors. Enhancing their knowledge and skills can help them identify defects early on and take corrective actions promptly. 8. Root Cause Analysis: When defects occur, conduct a thorough investigation to determine the root causes. Analyze the data collected from inspections, process monitoring, and quality control checks to identify the underlying issues. Once the root causes are identified, corrective actions can be implemented to prevent future occurrences. By implementing these measures, casting defects in metal casting machinery can be identified and corrected effectively, leading to improved casting quality and productivity.

- Q: How does metal casting machinery handle the removal of surface defects from the castings?

- Metal casting machinery handles the removal of surface defects from castings through various methods such as grinding, sanding, shot blasting, or using specialized tools and equipment. These processes help to smooth out any imperfections, such as rough edges, burrs, or unwanted material, resulting in a more refined and aesthetically pleasing final product.

- Q: What are the common troubleshooting techniques for metal casting machinery?

- There are several common troubleshooting techniques for metal casting machinery that can help identify and resolve issues efficiently. Here are a few of them: 1. Visual inspection: Start by visually inspecting the machinery for any obvious signs of damage, wear, or misalignment. Look for loose or broken parts, leaks, or any abnormalities that might be causing the problem. 2. Use diagnostic tools: Utilize diagnostic tools such as pressure gauges, thermometers, or vibration meters to measure and analyze different parameters. This can help identify specific areas or components that might be malfunctioning. 3. Check power supply: Ensure that the machinery is receiving a consistent and adequate power supply. Verify all electrical connections, fuses, and circuit breakers to rule out any power-related issues. 4. Lubrication: Check the lubrication system to ensure proper lubrication of moving parts. Inadequate lubrication can lead to increased friction, excessive heat, or even component failure. 5. Cleanliness: Maintain cleanliness in and around the machinery. Metal chips, debris, or dust accumulation can cause blockages or interfere with the operation of various components. Regular cleaning can help prevent such issues. 6. Adjust settings: Review and adjust the settings on the machinery, such as temperature, pressure, or speed controls, to ensure they are set correctly. Incorrect settings can result in suboptimal performance or even damage to the machinery. 7. Conduct trial runs: Perform trial runs with a small batch of metal to check if the machinery is functioning as intended. This can help identify any issues before starting a full-scale production run. 8. Consult manuals and reference guides: Review the manufacturer's manuals and reference guides for troubleshooting tips specific to your metal casting machinery. These resources often provide valuable insights into common issues and their solutions. 9. Seek expert advice: If you are unable to resolve the issue on your own, don't hesitate to seek the help of a qualified technician or the manufacturer's support team. They have the expertise and experience to diagnose and repair complex problems. Remember that safety should always be a top priority when troubleshooting metal casting machinery. Follow appropriate safety procedures, such as wearing personal protective equipment and disconnecting power sources before conducting any maintenance or repair work.

- Q: What are the common defects in metal casting and how can they be prevented?

- Common defects in metal casting include porosity, shrinkage, gas defects, and sand inclusion. Porosity occurs when gas or air is trapped within the metal during the casting process. This can lead to weak spots in the casting and reduce its structural integrity. To prevent porosity, proper gating and risering systems should be used to allow for the escape of gases. Additionally, ensuring the metal is properly degassed and using suitable mold materials can help reduce porosity. Shrinkage defects occur when the metal solidifies and contracts, causing voids or cracks in the casting. To prevent shrinkage defects, proper risering and gating systems should be designed to allow for proper feeding of molten metal into the casting. The use of chillers or cooling elements can also help control solidification rates and minimize shrinkage. Gas defects, such as blowholes or gas porosity, occur when gases are trapped in the metal during solidification. This can result in weak points in the casting. To prevent gas defects, proper mold and core venting should be provided to allow for the escape of gases. Controlling the melting and pouring processes can also help minimize gas defects. Sand inclusion defects occur when sand from the mold or core becomes embedded in the casting. This can weaken the metal and result in surface imperfections. To prevent sand inclusion, proper mold design and gating systems should be used to minimize sand erosion. Regularly cleaning and maintaining the molds can also help prevent sand inclusion. Overall, preventing defects in metal casting requires careful process planning and design, as well as proper control of the melting, pouring, and solidification processes. Regular inspections and quality control measures should also be implemented to identify and address any defects that may arise.

- Q: How are the defects related to cleaning prevented in metal casting machinery?

- Defects related to cleaning in metal casting machinery are prevented by implementing proper cleaning and maintenance procedures, such as regular inspections, thorough cleaning of the machinery components, and adhering to recommended cleaning agents and techniques. Additionally, using high-quality cleaning equipment and ensuring proper training of operators can help minimize defects and ensure efficient and effective cleaning in metal casting machinery.

- Q: Can metal casting machinery produce castings with consistent quality?

- Yes, metal casting machinery can produce castings with consistent quality. Metal casting machinery is designed to meet strict quality control standards and ensure that each casting produced meets the specified requirements. The machinery is equipped with advanced technologies and automation systems that enable precise control over the casting process, including temperature, pressure, and cooling rates. This helps to minimize variations and defects in the castings, resulting in consistent quality. Additionally, the machinery is regularly maintained and calibrated to ensure its optimal performance, further enhancing the consistency of the castings produced. Quality control measures such as inspection and testing are also implemented throughout the casting process to identify any deviations and ensure that only castings meeting the desired quality standards are approved. Overall, metal casting machinery is capable of producing castings with consistent quality through its advanced technology, automation systems, and stringent quality control measures.

Send your message to us

Half-Speed Steel Roll With High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords