Steel Rebar HRB400 Grade for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

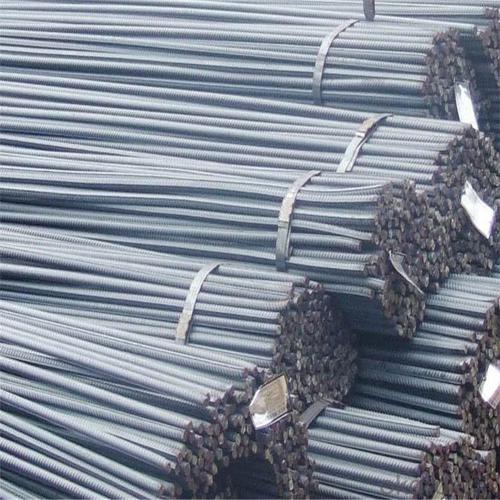

Steel Rebar HRB400 Grade for Building

Description of Steel Rebar HRB400 Grade for Building

1, Diameter: 5.5mm-10mm Steel Rebar HRB400 Grade for Building

10m- 40mm Steel Rebar HRB400 Grade for Building

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

2, Produce Process: hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

Chemical Composition of Steel Rebar HRB400 Grade for Building

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Steel Rebar HRB400 Grade for Building

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How can I determine the cooling water flow of square billet mold for special steel?

- Mold heat balance method. If the heat of the molten steel in the mould is taken away from the cooling water, the heat released by the solidification of the molten steel is equal to the amount taken away by the cooling water

- Q: Can special steel be used for making power generation equipment?

- Yes, special steel can be used for making power generation equipment. Special steels are specifically designed to have enhanced properties such as high strength, corrosion resistance, heat resistance, and wear resistance. These properties make special steel suitable for use in demanding applications such as power generation equipment, which often operates under high temperatures and pressures. Power generation equipment, such as turbines, boilers, and generators, require materials that can withstand harsh operating conditions and deliver reliable performance over an extended period. Special steel grades, such as stainless steels, nickel-based alloys, and heat-resistant steels, are commonly used in the construction of power plants and power generation equipment. Stainless steels are frequently used in power generation due to their excellent corrosion resistance, which is crucial for equipment exposed to high moisture or aggressive environments. Nickel-based alloys are renowned for their exceptional high-temperature strength, making them ideal for components subjected to extreme heat, such as turbine blades or exhaust systems. Heat-resistant steels, on the other hand, are specifically designed to retain their mechanical properties at elevated temperatures, making them suitable for applications such as boilers and heat exchangers. In summary, special steel offers a range of desirable properties that make it highly suitable for manufacturing power generation equipment. Its strength, corrosion resistance, heat resistance, and wear resistance make it an excellent choice for withstanding the demanding conditions found in power plants and ensuring the reliable and efficient generation of electricity.

- Q: What are the specific requirements for special steel used in the textile machinery industry?

- The specific requirements for special steel used in the textile machinery industry can vary depending on the specific application and machinery involved. However, there are some general requirements that are common in this industry. 1. Corrosion resistance: Textile machinery is often exposed to moisture, chemicals, and other corrosive substances. Therefore, the special steel used in this industry must have excellent corrosion resistance properties to ensure durability and longevity. 2. High strength: Textile machinery operates under high loads and stresses. Hence, the special steel used must have high strength to withstand these forces and prevent any deformation or failure. 3. Wear resistance: Textile machinery involves constant contact between different components, resulting in wear and tear. Therefore, the special steel used should have good wear resistance properties to minimize the effects of friction and prolong the lifespan of the machinery. 4. Heat resistance: Textile machinery often operates at high temperatures due to the friction generated during the manufacturing process. The special steel used should have excellent heat resistance to prevent any deformation or loss of mechanical properties under high temperature conditions. 5. Machinability: The special steel used in the textile machinery industry should be easily machinable to allow for the production of complex components with precise dimensions. This ensures that the machinery operates smoothly and efficiently. 6. Cost-effectiveness: While meeting all the above requirements, it is essential for the special steel used in the textile machinery industry to be cost-effective. Manufacturers aim to balance the performance and cost to ensure that the machinery remains competitive in the market without compromising on quality. It is important to note that these requirements can vary depending on the specific application within the textile machinery industry. Therefore, it is crucial for manufacturers and engineers to carefully evaluate the requirements of their machinery and select the appropriate special steel accordingly.

- Q: What are the safety benefits of using special steel?

- Using special steel can provide several safety benefits in various applications. One of the main advantages is its enhanced strength and durability compared to traditional steel. Special steel is often designed to withstand extreme conditions, such as high temperatures or corrosive environments, making it ideal for applications in industries like aerospace, automotive, and oil and gas. The high strength of special steel allows for the construction of safer and more reliable structures. It can withstand heavy loads, reducing the risk of structural failures or collapses. This is crucial in industries where the safety of workers, equipment, and the general public is of utmost importance. Another safety benefit of special steel is its resistance to corrosion. Corrosion can weaken structures and compromise their safety. Special steel is often alloyed with elements like chromium, nickel, or molybdenum, which provide excellent corrosion resistance. This makes it suitable for applications in marine environments, chemical processing plants, or any setting where exposure to moisture or chemicals is a concern. Special steel is also known for its ability to retain its mechanical properties at high temperatures. This makes it an excellent choice for applications where heat resistance is crucial, such as in the construction of fire-resistant structures or in the manufacturing of industrial ovens and furnaces. By using special steel in these applications, the risk of structural failure or fire-related accidents can be significantly reduced. Furthermore, special steel can offer improved fatigue resistance, which is important in applications subject to cyclic loading or vibration. Fatigue failure can occur when a material experiences repeated stress over time, leading to cracks and eventual failure. Special steel can be engineered to have excellent fatigue properties, reducing the likelihood of unexpected failures and improving the overall safety of structures or equipment. In summary, the safety benefits of using special steel include enhanced strength, durability, corrosion resistance, heat resistance, and fatigue resistance. These properties make special steel a reliable choice for industries where safety is a top priority, ensuring the protection of workers, equipment, and the general public.

- Q: How does special steel perform at high temperatures?

- Special steel performs exceptionally well at high temperatures due to its unique composition and properties. Unlike regular steel, special steel is specifically designed to withstand extreme heat conditions without losing its strength or structural integrity. It exhibits excellent thermal stability, resistance to oxidation, and maintains its hardness and toughness even at elevated temperatures. This makes special steel an ideal material for various applications that require reliable performance under high-temperature environments, such as in aerospace, power generation, and industrial processes.

- Q: How does special steel comply with international standards?

- Special steel complies with international standards through a rigorous quality control process that involves testing the material for its chemical composition, mechanical properties, and dimensional accuracy. These standards, such as ISO, ASTM, and DIN, ensure that the steel meets the required specifications and performance criteria for various applications. Manufacturers also follow strict production guidelines and undergo regular audits to maintain compliance with these international standards.

- Q: How does special steel contribute to the automotive material recycling?

- Special steel plays a significant role in automotive material recycling by providing high-strength and durable components that can be easily disassembled and reused. Its properties allow for effective recycling processes, enabling the extraction of valuable materials from end-of-life vehicles. This contributes to the sustainability of the automotive industry by reducing waste and conserving resources.

- Q: How is special steel tested for quality control?

- Special steel is tested for quality control through a series of rigorous inspections and tests. These can include chemical composition analysis, mechanical property testing, non-destructive testing, and dimensional inspections. Additionally, special steel may undergo heat treatment testing, surface quality evaluations, and microstructure examinations to ensure it meets the required standards and specifications.

- Q: How does special steel contribute to the packaging industry?

- Special steel contributes to the packaging industry by providing high strength, durability, and corrosion resistance, making it ideal for manufacturing packaging materials and machinery. It ensures the integrity and safety of packaging products, prevents damage during transportation, and extends the shelf life of perishable goods. Additionally, special steel's versatility allows for innovative packaging designs and customization, meeting the specific requirements and demands of different industries.

- Q: What are the different casting methods used for special steel?

- For special steel, various casting methods are commonly utilized, depending on the specific requirements and needs of the application. These methods encompass investment casting, sand casting, continuous casting, and centrifugal casting. 1. Investment casting: To create the desired part, a wax pattern is made and coated with a ceramic shell. The wax is melted away, leaving a hollow shell that is then filled with molten steel. After solidification, the ceramic shell is broken, yielding the final part. Investment casting enables the production of accurate and intricate shapes, making it ideal for high-quality and precise special steel components. 2. Sand casting: Among the oldest and most prevalent casting techniques, sand casting involves forming a mold using a mixture of sand and a binder like clay. The mold is shaped around a pattern of the desired part and molten steel is poured into it. Upon cooling and solidification, the casting is complete. Sand casting is versatile and cost-effective, suitable for producing large and heavy special steel components. 3. Continuous casting: This method is commonly employed for manufacturing long steel products such as bars, rods, and billets. Molten steel is continuously poured into a water-cooled mold, which solidifies the outer surface. The solidified steel is then continuously withdrawn as more molten steel is poured in. Continuous casting ensures high-quality steel with a consistent cross-section, devoid of defects. 4. Centrifugal casting: In this technique, molten steel is poured into a rotating mold. The centrifugal force drives the molten steel towards the outer walls, resulting in a dense and compact casting with enhanced mechanical properties. Centrifugal casting is particularly suitable for producing cylindrical or tubular special steel components such as pipes and rings. In summary, the selection of a casting method for special steel hinges on factors like part complexity, required quality and accuracy, component size and shape, and production volume. Each method has its advantages and limitations, necessitating careful consideration to determine the most appropriate casting technique for a specific application.

Send your message to us

Steel Rebar HRB400 Grade for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords