Hrb400 Steel Rebar Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hrb400 Steel Rebar

Description of Hrb400 Steel Rebar

1, Diameter: 5.5mm-10mm Hrb400 Steel Rebar

10m- 40mm Hrb400 Steel Rebar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Hrb400 Steel Rebar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

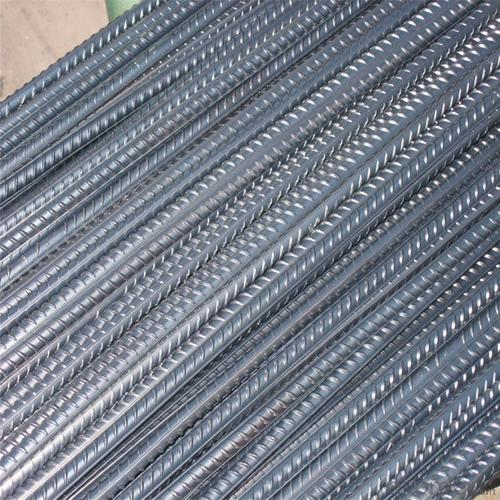

Products Show of Hrb400 Steel Rebar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What is the purpose of annealing in special steel production?

- The purpose of annealing in special steel production is to improve the mechanical properties and overall quality of the steel. Annealing is a heat treatment process in which the steel is heated to a specific temperature and then slowly cooled, typically in a controlled atmosphere. This process helps to relieve any internal stresses or strains that may have developed during previous manufacturing processes such as rolling or forging. During annealing, the steel's microstructure undergoes changes, resulting in a more refined and homogeneous material. The process allows for the redistribution of atoms, which helps to eliminate defects, improve grain structure, and enhance the steel's toughness, ductility, and machinability. Annealing also helps to reduce the hardness of the steel, making it easier to work with and shape. It can also improve the steel's resistance to cracking and enhance its resistance to corrosion or other environmental factors. Additionally, annealing can help to achieve desired physical properties such as increased hardness or improved magnetic properties in certain special steel alloys. Overall, the purpose of annealing in special steel production is to optimize the steel's properties and ensure it meets the specific requirements of its intended application, whether it be in industries such as automotive, aerospace, or manufacturing.

- Q: What are the different techniques used for joining special steel?

- Some of the different techniques used for joining special steel include welding, brazing, soldering, and mechanical fastening. Welding involves melting the surfaces of the steel pieces to be joined and fusing them together. Brazing and soldering involve using a filler material that melts at a lower temperature than the steel to join the pieces together. Mechanical fastening techniques, such as bolts, screws, or rivets, can also be used to join special steel components together.

- Q: How does special steel contribute to the telecommunications industry?

- Special steel plays a crucial role in the telecommunications industry by providing the necessary materials for the production of various components such as cables, connectors, and transmission towers. It offers exceptional strength, durability, and resistance to corrosion, allowing for reliable and long-lasting infrastructure. Whether it's in the form of high-tensile steel wires for cables or corrosion-resistant steel for towers, special steel ensures efficient and uninterrupted communication networks, supporting the growth and advancement of the telecommunications industry.

- Q: What are the different non-destructive testing methods for special steel?

- There are several non-destructive testing methods for special steel, including visual inspection, ultrasonic testing, radiographic testing, magnetic particle testing, and liquid penetrant testing. These methods allow for the detection of surface and subsurface defects, such as cracks, voids, or inclusions, without causing any damage to the material. Each method has its own advantages and limitations, and the choice of testing method depends on the specific requirements and characteristics of the special steel being evaluated.

- Q: How does special steel contribute to sustainability efforts?

- Special steel is a key player in sustainability initiatives for various reasons. To begin with, its durability and long lifespan make it highly sought after. It boasts exceptional resistance to corrosion, wear, and tear, enabling it to endure harsh conditions and heavy use. By prolonging the lifespan of products made with special steel, the need for frequent replacements is minimized. Consequently, this conserves natural resources and diminishes environmental impact by reducing resource consumption and waste generation. Furthermore, special steel is renowned for its recyclability. It can be melted down and reprocessed multiple times without compromising its properties or quality. This quality makes it a valuable material within the circular economy, where resources are reused and recycled to reduce reliance on virgin materials. The recycling process for special steel requires less energy compared to producing steel from raw materials, leading to lower greenhouse gas emissions and energy consumption. Moreover, special steel finds extensive application in energy-efficient endeavors. For instance, it is heavily employed in the manufacturing of wind turbines, which produce renewable energy. By providing a material capable of withstanding the demanding conditions of wind turbines, special steel contributes to the expansion of clean energy sources. This, in turn, reduces dependence on fossil fuels, curbs carbon emissions, and aids in mitigating climate change. Lastly, special steel plays a vital role in the transportation industry. It is utilized in the production of lightweight, fuel-efficient vehicles like electric cars. Through reducing vehicle weight, special steel improves fuel efficiency and diminishes greenhouse gas emissions. Additionally, special steel is instrumental in constructing infrastructure for electric vehicle charging stations, facilitating the transition to cleaner transportation systems. In conclusion, special steel's contributions to sustainability are extensive. Its properties and applications promote durability, recyclability, energy efficiency, and clean energy generation. By conserving resources, reducing waste, and combating climate change, special steel emerges as a crucial material in shaping a more sustainable future.

- Q: What are the different molding grades of special steel?

- Various industries and applications utilize several distinct molding grades of special steel. Some well-known molding grades are: 1. P20: This grade finds wide usage in the production of plastic injection molds, die casting, and extrusion dies. It boasts excellent machinability, high hardness, and good polishability, making it suitable for high-precision molding operations. 2. H13: Primarily used for die casting and forging applications, this grade is a hot work tool steel. It offers high toughness, good heat resistance, and excellent wear resistance, making it suitable for molding processes in high-temperature environments. 3. S7: Commonly employed in molding applications requiring high impact resistance, this grade is a shock-resistant tool steel. It provides good hardness, toughness, and machinability, making it ideal for applications like shear blades and hammer dies. 4. NAK80: Often utilized for high-quality mirror surface molds and precision molding, this grade is a pre-hardened mold steel. It offers high polishability, excellent dimensional stability, and good wear resistance, making it suitable for producing parts with demanding surface finish requirements. 5. 420SS: This grade, a stainless steel, is commonly used in molding applications that require corrosion resistance. It provides good hardness, moderate strength, and excellent corrosion resistance, making it suitable for applications such as medical devices and food processing equipment. These examples represent just a fraction of the available molding grades of special steel on the market. Each grade possesses distinct properties and characteristics that render them suitable for various molding applications. It is crucial to select the appropriate grade based on the specific requirements of the molding process to ensure optimal performance and durability.

- Q: What industries rely on special steel?

- Several industries rely on special steel, including automotive, aerospace, construction, energy, and manufacturing. Special steel is known for its exceptional strength, durability, and resistance to corrosion, making it an essential material in these sectors. It is used for various applications such as structural components, machinery parts, tools, pipelines, and turbines, among others.

- Q: What is the cost of special steel compared to regular steel?

- The cost of special steel is typically higher than that of regular steel due to its unique properties and manufacturing processes.

- Q: What are the thermal conductivity properties of special steel?

- Special steel, also known as alloy steel, exhibits high thermal conductivity properties. This is due to the presence of various alloying elements, such as chromium, nickel, and manganese, which enhance heat transfer. The specific thermal conductivity value of special steel depends on its composition and can vary, but it generally has good heat transfer capabilities.

- Q: How does special steel contribute to reducing energy consumption?

- Special steel contributes to reducing energy consumption in several ways. Firstly, special steel is known for its high strength and durability, which allows for the construction of lighter and more efficient structures. This means that less material is required, resulting in reduced energy consumption during the manufacturing and transportation processes. Additionally, special steel has excellent heat resistance properties, making it ideal for the production of energy-efficient appliances and machinery. By using special steel in these applications, energy losses due to heat transfer are minimized, resulting in lower energy consumption. Furthermore, special steel is often used in the production of renewable energy technologies such as wind turbines and solar panels. By utilizing these energy sources, which rely on steel components, the overall demand for fossil fuels and non-renewable energy is reduced, consequently decreasing energy consumption. Overall, the use of special steel in various industries plays a significant role in reducing energy consumption and promoting sustainability.

Send your message to us

Hrb400 Steel Rebar Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords