Steel Prop & Tripod for Build

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

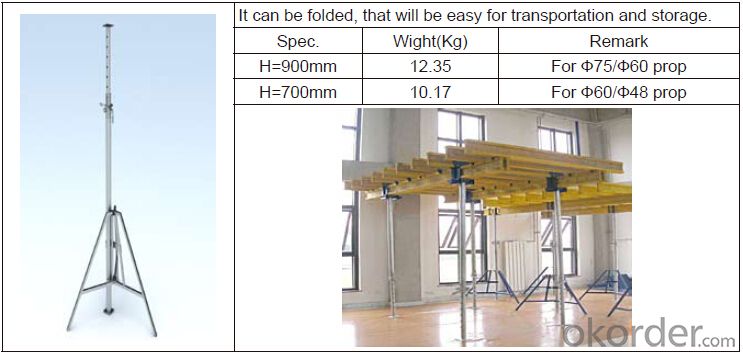

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

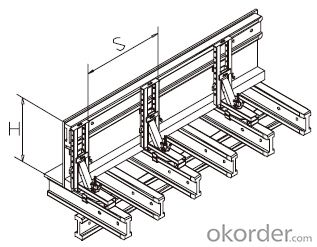

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: What are the potential risks or hazards associated with using steel props?

- There are several potential risks or hazards associated with using steel props in construction or other applications. Firstly, steel props may not be suitable for all types of loads or applications. If the load exceeds the capacity or design limits of the props, they may fail or collapse, leading to accidents, injuries, or property damage. Secondly, steel props rely on proper installation and positioning to be effective and safe. If not properly installed, the props may not provide adequate support and stability, leading to structural instability or collapse. Additionally, if the props are not positioned correctly, they may create uneven or unbalanced loads, which can also compromise the stability of the structure. Another potential risk is associated with the use of damaged or worn-out steel props. Over time, props may become corroded, weakened, or damaged due to various factors such as exposure to harsh weather conditions or mishandling. Using damaged or worn-out props can significantly increase the risk of structural failure or collapse. Furthermore, steel props can pose risks during the assembly and dismantling process. If not done carefully and according to proper procedures, workers may be at risk of being struck by falling props or other materials. Additionally, mishandling or improper storage of steel props can lead to injuries from cuts, bruises, or strains. Lastly, steel props may also pose risks related to their weight and size. They can be heavy and difficult to handle, especially in confined spaces or when working at heights. Improper lifting techniques or inadequate training can lead to accidents, injuries, or strains. To mitigate these risks, it is crucial to ensure that steel props are used within their design limits, properly installed and positioned, regularly inspected for damage, and replaced when necessary. Adequate training and supervision should be provided to workers involved in the assembly, dismantling, and handling of steel props. Additionally, workers should use appropriate personal protective equipment and follow safe work practices to minimize the potential hazards associated with using steel props.

- Q: What is the meaning of steel support flange connection

- The connection between segments is made of high strength bolt connection

- Q: How do you ensure proper coordination between different trades when using steel props?

- Proper coordination between different trades when using steel props can be ensured through effective communication, regular meetings, and detailed planning. This includes sharing project schedules, specifications, and drawings with all relevant trades to ensure a clear understanding of their respective responsibilities and timelines. Additionally, having a designated project manager or coordinator who oversees the activities of different trades and facilitates communication among them can greatly enhance coordination. Regular site inspections and collaborative problem-solving sessions can also help identify and resolve any potential conflicts or issues that may arise during the construction process.

- Q: Can steel props be used for temporary support in stadium roof construction?

- Yes, steel props can be used for temporary support in stadium roof construction. Steel props are commonly used in construction projects to provide temporary support to structures such as walls, beams, or roofs. They are adjustable and can be easily installed and removed as needed. Steel props are strong, durable, and can withstand the weight and pressure of the roof during construction. They provide stability and support, ensuring the safety of the workers and the integrity of the structure.

- Q: How long does a steel prop typically last?

- Various factors, including prop quality, applied load, and frequency of use, typically influence the lifespan of a steel prop. On average, these props can endure for approximately 5 to 10 years. By faithfully following the manufacturer's guidelines and conducting regular maintenance, one can considerably prolong a prop's life. It is crucial to promptly replace any prop showing indications of wear and tear, such as rust, cracks, or deformation, to ensure ongoing safety.

- Q: Are steel props suitable for use in industrial plants?

- Yes, steel props are suitable for use in industrial plants. Steel props, also known as adjustable steel props or steel acrow props, are widely used in various industrial applications due to their strength, durability, and versatility. Industrial plants often require support structures to provide stability and reinforcement to heavy machinery, equipment, or structures. Steel props offer a reliable and robust solution for such needs. One of the main advantages of steel props is their adjustable height feature. They can be extended or retracted to the desired length, allowing for easy installation and customization to specific plant requirements. This adjustability makes them suitable for supporting different loads and accommodating various working heights, making them versatile for use in different areas of an industrial plant. Steel props are designed to withstand heavy loads and provide excellent load-bearing capacity. They are made of high-quality steel, which ensures their strength and durability, making them suitable for withstanding the harsh conditions often found in industrial plants, such as vibrations, impacts, or extreme temperatures. Furthermore, steel props are easy to install, dismantle, and reposition, which is crucial in industrial plants where flexibility and adaptability are necessary. They can be quickly adjusted or relocated as per the changing needs of the plant, saving time and effort. Additionally, steel props are cost-effective compared to other support options. Their long lifespan and low maintenance requirements make them a cost-efficient choice for industrial plants, where budget considerations are crucial. In conclusion, steel props are highly suitable for use in industrial plants. Their strength, durability, adjustability, and cost-effectiveness make them an ideal choice for providing support and stability to heavy machinery, equipment, or structures in industrial settings.

- Q: Can steel props be used in the construction of temporary road barriers?

- Yes, steel props can be used in the construction of temporary road barriers. Steel props are commonly used in construction projects to support structures such as scaffolding and formworks. They are designed to provide stability and strength, making them suitable for use in various applications, including temporary road barriers. Steel props can be easily adjusted to different heights and securely anchored to the ground, ensuring the stability and durability of the road barriers. Moreover, steel props offer excellent load-bearing capacity, making them suitable for withstanding the impact of vehicles and other external forces.

- Q: What are the maximum and minimum heights available for steel props?

- The maximum and minimum heights available for steel props can vary depending on the specific manufacturer and model. However, in general, steel props can typically be adjusted to a minimum height of around 1.8 meters (6 feet) and a maximum height of approximately 4.8 meters (16 feet).

- Q: What are the common applications of steel props in construction?

- Steel props, also known as adjustable steel props or acrow props, are widely used in construction for various applications. One common use of steel props is to provide temporary support during the construction or renovation of buildings. These props are adjustable in height, allowing them to be easily set up to support formwork, scaffolding, or beams. Steel props are also commonly used to stabilize walls or structures during excavation or demolition work. Additionally, they are used in the construction of bridges, tunnels, and other large structures where temporary support is necessary. Overall, steel props play a crucial role in ensuring the safety and stability of construction projects.

- Q: What are the main considerations when using steel props for supporting temporary ramps?

- When it comes to supporting temporary ramps with steel props, there are several crucial factors to keep in mind. First and foremost, it is essential to ensure that the steel props used are strong and capable of bearing the specific load requirements of the ramp. These props should be able to support not only the weight of the ramp itself but also any additional loads, such as people, equipment, or vehicles. To determine the appropriate size and strength of the steel props needed, it is important to consult engineering specifications and guidelines. Secondly, the stability and rigidity of the props must be carefully evaluated. To prevent any movement or shifting while the ramp is being used, the props should be securely anchored to the ground or a stable surface. This is particularly crucial in cases where the ramp is subjected to heavy loads or is located in high-traffic areas. It is also important to implement adequate bracing and support mechanisms to ensure overall stability of the ramp structure. Additionally, the positioning and spacing of the steel props should be taken into consideration. They should be strategically placed along the length of the ramp to provide uniform support, ensuring that the weight is evenly distributed. The number of props required will depend on the size and width of the ramp, as well as the expected load. To prevent any sagging or bending in the ramp, it is important to space the props at regular intervals. Furthermore, regular monitoring of the condition and maintenance of the steel props is necessary. Promptly addressing any signs of corrosion, wear, or damage is crucial to maintain the structural integrity and safety of the ramp. Regular inspections and maintenance should be conducted to ensure that the props are in proper working condition. Lastly, compliance with relevant safety regulations and standards is of utmost importance when using steel props to support temporary ramps. Local building codes and regulations may specify specific requirements for the design, installation, and use of such props. It is essential to consult with a qualified engineer or construction professional to ensure that the props meet all necessary safety standards. In conclusion, the main factors to consider when using steel props to support temporary ramps include their strength and load-bearing capacity, stability and rigidity, positioning and spacing, condition and maintenance, as well as compliance with safety regulations. By carefully addressing these factors, the use of steel props can provide a secure and dependable support system for temporary ramps.

Send your message to us

Steel Prop & Tripod for Build

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords