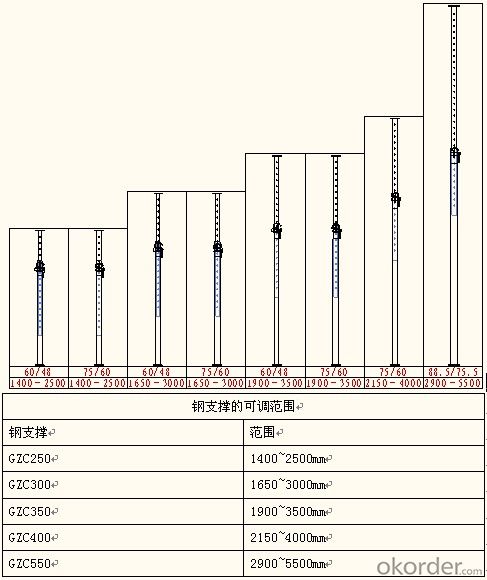

steel props

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

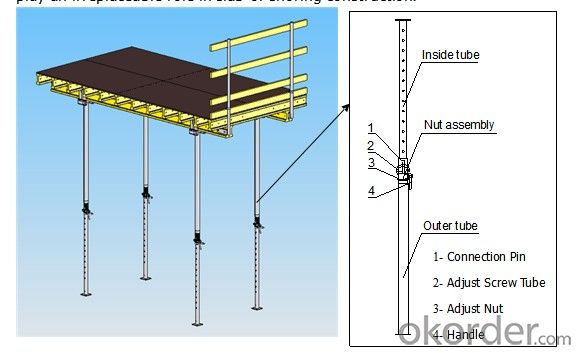

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: Can steel props be used in all weather conditions?

- Steel props can generally be used in all weather conditions, as they are designed to be durable and resistant to various environmental factors. Steel is known for its strength and ability to withstand extreme temperatures, humidity, rain, and snow. However, it is important to note that certain precautions may need to be taken depending on the specific weather conditions. For example, in extremely cold temperatures, steel props may require additional insulation or protection to prevent freezing or damage. Similarly, in areas with high humidity or near saltwater, corrosion-resistant coatings or regular maintenance may be necessary to prevent rust and ensure the longevity of the props. Overall, while steel props are versatile and can be used in various weather conditions, it is important to consider the specific climate and take appropriate measures to ensure their effectiveness and durability.

- Q: Are steel props suitable for temporary or permanent structures?

- Steel props are commonly used in construction projects to provide temporary support to structures during construction or repair work. These props are designed to withstand heavy loads and provide stability to structures until they are able to support themselves. While steel props are primarily used for temporary structures, they can also be suitable for certain permanent structures. In some cases, steel props may be used as permanent supports in buildings or structures where additional strength or reinforcement is required. However, the suitability of steel props for permanent structures depends on various factors such as the design requirements, load-bearing capacity, and the specific needs of the project. It is important to consult with a structural engineer or a professional in the construction industry to determine whether steel props are appropriate for a specific permanent structure. Ultimately, the decision to use steel props for temporary or permanent structures should be based on careful evaluation and consideration of the specific requirements and conditions of the project.

- Q: Are steel props adjustable for supporting inclined surfaces?

- Yes, steel props are adjustable and can be used to support inclined surfaces. The adjustable features of steel props allow for setting the desired height and angle, making them suitable for various inclined surfaces.

- Q: Can steel props be used for supporting temporary residential structures?

- Yes, steel props can be used for supporting temporary residential structures. Steel props, also known as adjustable steel props or steel acrow props, are commonly used in construction projects to provide temporary support to structures. They are designed to bear heavy loads and provide stability during construction or renovation activities. For temporary residential structures, such as mobile homes, portable cabins, or temporary shelters, steel props can be an effective solution. They can be easily adjusted to the desired height and can provide the necessary support for the structure. Steel props are strong, durable, and have a high load-bearing capacity, making them suitable for various types of temporary residential structures. However, it is important to ensure that the steel props are properly installed and meet the specific requirements of the structure. Professional advice and expertise should be sought to determine the appropriate size, number, and placement of steel props to ensure the safety and stability of the temporary residential structure. Additionally, regular inspections and maintenance should be carried out to ensure that the steel props remain in good condition and continue to provide the necessary support. Overall, steel props can be a reliable choice for supporting temporary residential structures, but proper planning, installation, and maintenance are essential to ensure their effectiveness and safety.

- Q: How do you ensure proper stability when using steel props on soft soil?

- To ensure proper stability when using steel props on soft soil, there are several measures that can be taken: 1. Soil investigation: Conduct a thorough soil investigation to understand the properties and characteristics of the soft soil. This will help in determining the appropriate design and dimension of the steel props, considering the specific soil conditions. 2. Load calculation: Calculate the load that will be imposed on the steel props. This includes the weight of the structure being supported, any additional loads or forces, and the factor of safety. This will ensure that the steel props are strong enough to bear the required load without causing any instability. 3. Proper placement: Place the steel props at the correct locations, considering the layout and load distribution of the structure. This will help in evenly distributing the load and minimizing any localized pressure on the soft soil. 4. Adequate spacing: Ensure proper spacing between the steel props. This will prevent excessive load concentration on any particular area of the soft soil, reducing the risk of instability. 5. Reinforcement and anchoring: If necessary, reinforce the soft soil using techniques such as soil stabilization or ground improvement methods. This can involve adding materials like compacted soil, stone columns, or geosynthetics to improve the soil's strength and stability. Additionally, anchor the steel props securely to prevent any lateral movement or tilting. 6. Monitoring and maintenance: Regularly monitor the performance of the steel props and the stability of the soft soil. This can involve visual inspections, measurements, and periodic assessments to identify any signs of instability or potential issues. Prompt action should be taken to address any problems and ensure the stability of the steel props and the surrounding soil. By implementing these measures, one can ensure that steel props are appropriately designed, positioned, and supported to provide proper stability when working on soft soil conditions.

- Q: How do you prevent unauthorized access to steel props on construction sites?

- Preventing unauthorized access to steel props on construction sites is crucial for the safety of workers and the integrity of the project. Here are some measures that can be taken to prevent unauthorized access to steel props: 1. Secure perimeter: Erect a secure perimeter around the construction site using fences and barriers. Clearly mark restricted areas with signs indicating that unauthorized access is prohibited. 2. Access control: Implement strict access control measures such as controlled entry points and identification systems. This can include using access cards, biometric scanners, or security personnel to regulate who enters the construction site. 3. Surveillance systems: Install CCTV cameras strategically throughout the construction site to monitor and record activities. These cameras should cover areas where steel props are stored or being used. Ensure that the surveillance system is regularly maintained and functioning properly. 4. Lighting: Adequate lighting can deter unauthorized access by making it more difficult for individuals to enter the construction site undetected. Install lighting systems that illuminate all areas, particularly those where steel props are stored. 5. Locking mechanisms: Secure steel prop storage areas with robust locking mechanisms such as padlocks or combination locks. Ensure that these locks are regularly checked and replaced if necessary. 6. Security personnel: Employ trained security personnel to patrol the construction site and monitor access points. They can address any unauthorized access attempts promptly and effectively. 7. Regular inventory checks: Conduct regular inventory checks of steel props to ensure that none have been tampered with or stolen. Keep a record of all steel props and their locations to quickly identify any discrepancies. 8. Employee training: Educate all construction site workers about the importance of preventing unauthorized access to steel props. Promote a culture of security and vigilance among the workforce. 9. Alarm systems: Install alarm systems that can be triggered by unauthorized entry attempts. These alarms should be loud and easily audible to alert security personnel or nearby workers. 10. Regular site inspections: Conduct regular inspections of the construction site to identify any vulnerabilities or weak points in the security measures. Continuously improve security protocols based on these inspections. By implementing these preventive measures, construction site managers can significantly reduce the risk of unauthorized access to steel props, ensuring the safety of workers and the successful completion of the project.

- Q: Can steel props be used in the construction of temporary storage or warehouse structures?

- Steel props, also referred to as adjustable steel props or scaffolding props, have the ability to be utilized in the construction of temporary storage or warehouse structures. Commonly seen in the construction industry, these steel props serve to provide support and stability to such temporary structures. Their purpose is to offer temporary assistance during construction or renovation work, and they prove particularly advantageous when it comes to the construction of temporary storage or warehouse structures. Not only are steel props robust and long-lasting, but they are also adjustable, making them well-suited for a range of temporary construction requirements. Furthermore, their installation and dismantling process is straightforward, allowing for flexibility throughout the construction phase. As a whole, steel props are a dependable and effective option for supporting temporary storage or warehouse structures during construction or renovation endeavors.

- Q: How do steel props contribute to the overall stability of a building?

- Steel props, also known as steel shoring or scaffolding, play a crucial role in ensuring the overall stability of a building during construction or renovation. These temporary supports provide structural integrity and prevent the collapse of walls, floors, or ceilings. One key contribution of steel props to the stability of a building is their ability to distribute and transfer loads. By strategically placing these props at critical load-bearing points, they effectively bear the weight of the structure and allow for safe and controlled load transfer. This even distribution of loads helps prevent excessive stress on specific areas, thereby reducing the risk of structural failure. Additionally, steel props provide vertical support and prevent excessive deflection or sagging of structural elements. During construction, when walls or other load-bearing structures are removed or altered, steel props are used to temporarily support the remaining load. This ensures that the building remains stable and secure, preventing any potential collapse or damage. Furthermore, steel props offer adjustability, allowing for precise alignment and leveling of structural components. This adjustability is particularly important when dealing with uneven ground or varying heights of different building elements. By providing stability and alignment, steel props contribute to the overall structural integrity of the building, ensuring that all components are properly supported and in place. Moreover, steel props are designed to withstand heavy loads and provide strong resistance against lateral forces, such as wind or seismic activity. By resisting these external forces, they enhance the overall stability of the building and protect it from potential damage. In summary, steel props play a vital role in contributing to the overall stability of a building during construction or renovation. They distribute and transfer loads, provide vertical support, offer adjustability, and resist lateral forces. By fulfilling these functions, steel props ensure that the building remains safe and structurally sound throughout the construction process.

- Q: Are steel props suitable for supporting temporary manufacturing facilities?

- Yes, steel props are suitable for supporting temporary manufacturing facilities. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary structures to provide support and stability. They are typically made of high-quality steel and are designed to withstand heavy loads and provide a secure foundation. Steel props offer several advantages that make them suitable for supporting temporary manufacturing facilities. Firstly, they are adjustable in height, allowing for flexibility in supporting structures of different sizes and heights. This adjustability feature makes them versatile and adaptable to various manufacturing facility requirements. Moreover, steel props are highly durable and can withstand the demanding conditions of a manufacturing environment. They are designed to provide structural support and stability, ensuring the safety of the temporary facility and the workers within it. Steel props are often tested and certified to meet industry standards, guaranteeing their reliability and safety. Additionally, steel props are relatively easy to install and dismantle, making them ideal for temporary structures. They can be quickly set up and adjusted as needed, allowing for efficient and cost-effective construction of temporary manufacturing facilities. Their lightweight nature also makes them easy to transport and maneuver, further adding to their suitability for temporary structures. In conclusion, steel props are indeed suitable for supporting temporary manufacturing facilities. Their adjustability, durability, and ease of installation make them a practical choice for providing stable support in a temporary manufacturing environment.

- Q: Are steel props suitable for supporting roof structures?

- Roof structures can be effectively supported by steel props. Commonly referred to as adjustable steel props or steel acrow props, these props are frequently utilized in construction to provide temporary support for roofs, formwork, and scaffolding. They are specifically designed to offer reliable and adjustable support, which renders them highly suitable for various types of roof structures. The strength and durability of steel props are derived from their high-quality steel composition. They possess the capability to withstand heavy loads and can be adjusted to the desired height, thereby facilitating precise support. This adjustable feature proves particularly advantageous when working with roofs that are uneven or sloping, as the props can be individually adjusted to guarantee a level and stable support system. Furthermore, steel props are characterized by their versatility and user-friendly nature. Available in different sizes and load capacities, they can be customized according to the specific requirements of the roof structure. Their quick setup and dismantling capabilities make them a convenient choice for temporary support during construction or renovation projects. Moreover, steel props offer a safe and secure support system for roof structures. Their robust construction ensures stability and minimizes the risk of collapse or accidents. They are designed to distribute the load evenly, thereby preventing the occurrence of concentrated stress points that could compromise the integrity of the roof. In conclusion, steel props represent an excellent option for supporting roof structures. Their strength, adjustability, versatility, and safety features render them highly suitable for a wide range of construction projects. Whether it is a small residential roof or a large commercial structure, steel props can provide the necessary support to ensure a stable and secure roof system.

Send your message to us

steel props

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords