Steel prop & Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp:

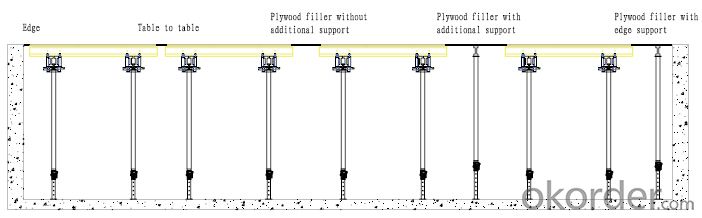

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used for supporting elevated platforms?

- Yes, steel props can be used for supporting elevated platforms. Steel props are commonly used in construction and scaffolding to provide temporary support for various structures, including elevated platforms. Steel props offer strength, stability, and adjustability, making them suitable for safely supporting elevated platforms during construction or other temporary needs.

- Q: What are the common accessories used for connecting multiple steel props?

- Various accessories are utilized for connecting multiple steel props, including: 1. Connectors for props: These connectors are specifically designed to attach and secure steel props together. They often incorporate a threaded design, allowing for easy tightening and adjustment. 2. Pins for props: Prop pins are employed to lock the props in place after they have been connected. They are inserted through the holes in the connectors, providing additional stability and support. 3. Sleeves for props: Prop sleeves are used to seamlessly join two or more steel props together. Typically made of steel or aluminum, they are designed to slide over the ends of the props, creating a secure connection. 4. Nuts for props: Prop nuts are utilized to secure the connectors and prop sleeves in place. They are tightened onto the threaded portion of the props, imparting additional stability and strength to the connection. 5. Wedges for props: Prop wedges are employed to secure the props against the supporting structure. They are positioned between the props and the structure, often made of wood or rubber to prevent surface damage. 6. Base plates for props: Base plates are employed to evenly distribute the load of the props and provide a stable foundation. They are placed beneath the props and are frequently made of steel or concrete. 7. Couplers for props: Prop couplers are used to connect two or more props in a straight line. They are typically employed when props need to be extended for reaching greater heights or spanning longer distances. These accessories are indispensable for ensuring the safe and efficient utilization of steel props in construction and scaffolding applications. By appropriately connecting and securing multiple props, they confer stability, support, and strength to the overall structure.

- Q: Set up bearing platform, 9 meters long, width of 4 meters, height of 8.5 meters, the support of the corner of the 4, the length of the direction of the middle of the 4.5 meters (middle), bearing capacity of 150 tons, supporting columns need to choose how much H steel, beams need to choose how much of the H steel, how to calculate?

- Since there are 150 tons of concentrated load in the middle of the bearing platform, in addition to meet the structural strength requirements, but also to meet the structural requirements of grace

- Q: Can steel props be used in the construction of underground metro systems?

- Indeed, underground metro systems can utilize steel props in their construction. These props are frequently employed in construction projects to offer temporary support and stabilization to structures. When it comes to underground metro systems, steel props can serve as support for the tunnel walls and ceilings during excavation and construction. Steel props are favored in underground construction due to their robustness, longevity, and ability to bear heavy loads. They have the capacity to withstand the immense pressures and weights exerted by the surrounding soil and rock, ensuring the stability and safety of the underground structures. Moreover, steel props are adaptable and adjustable, allowing for customization to suit various tunnel dimensions and specifications. They can be easily installed and removed as the construction progresses, making them a cost-effective solution for temporary support. Additionally, steel props can be combined with other construction techniques and materials, such as shotcrete and steel beams, to enhance the overall stability and strength of the underground metro system. All in all, steel props are a dependable and widely employed choice in the construction of underground metro systems. They provide the necessary support and stability required for safe and efficient construction.

- Q: Quota take template of reinforced concrete foundation for the 1 steel formwork support 2 steel formwork supporting steel formwork support 3 Wood 4 steel formwork concrete support selection

- In theory, according to the actual use of the corresponding template template,General composite template,Steel formwork for irregular concrete,

- Q: Can steel props be used in bridge construction?

- Steel props have the capability to be utilized in bridge construction. In the realm of construction projects, steel props, also referred to as temporary supports or shoring systems, are commonly employed to furnish temporary support to structures throughout the construction or repair process. They are specifically engineered to endure substantial loads and furnish stability to the structure. In the context of bridge construction, steel props can be employed to provide support to the bridge deck, beams, or arches during the construction phase, thereby enabling a safe and efficient construction process. Once the bridge construction has reached completion, the steel props can be dismantled or repurposed for future undertakings. All in all, steel props are versatile and dependable tools that can be effectively employed in bridge construction projects.

- Q: How do you prevent damage to steel props during construction activities?

- There are several measures that can be taken to prevent damage to steel props during construction activities: 1. Proper handling and storage: Steel props should be handled with care to avoid dropping or dragging them on rough surfaces. When not in use, props should be stored in a clean, dry area away from any potential hazards or heavy machinery. 2. Adequate support: Steel props should be positioned on a stable and level surface to ensure proper load distribution. The ground should be prepared beforehand, removing any loose debris or uneven surfaces that could cause the props to shift or collapse. 3. Regular inspections: It is important to regularly inspect steel props for any signs of damage or wear. Any props with visible defects, such as cracks, dents, or corrosion, should be removed from service immediately and replaced with new ones. 4. Protective measures: During construction activities, steel props should be protected from potential damage caused by falling debris, heavy equipment, or accidental impacts. Using protective covers or barriers can help shield the props from harm. 5. Proper installation: Steel props should be installed correctly according to the manufacturer's guidelines and recommendations. This ensures that they are able to withstand the intended loads and forces without becoming compromised or damaged. 6. Training and awareness: Construction workers should receive adequate training on the proper handling and usage of steel props. They should be made aware of the potential risks and consequences of mishandling or damaging the props, and encouraged to follow best practices at all times. By following these preventive measures, the risk of damage to steel props during construction activities can be minimized, ensuring their longevity and effectiveness in supporting structures.

- Q: What are the common accessories used for stabilizing steel props?

- The common accessories used for stabilizing steel props include base plates, bracing frames, cross braces, diagonal braces, and adjustable jacks. These accessories help to provide additional support and stability to steel props, ensuring their safe and efficient use in construction projects.

- Q: Can steel props be used for supporting temporary seating arrangements or bleachers?

- Yes, steel props can be used for supporting temporary seating arrangements or bleachers. Steel props are commonly used in construction and temporary structures due to their strength and stability.

- Q: The support system of the steel roof structure of a single storey workshop is composed of

- The roof support system of single storey steel structure workshop is generally: 1 lateral horizontal bracing; 2 vertical horizontal bracing; the vertical support of the 3; the tie bar of the 4.

Send your message to us

Steel prop & Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords